|

Langley Research CenterTurbulence Modeling Resource |

Exp: CFDVAL2004 Case 3: Flow over a Hump Model (Actuator Control)

Return to: CFDVAL2004 - Intro Page

Return to: Data from Experiments - Intro Page Return to: Turbulence Modeling Resource Home Page

Case 3 is a part of the

ERCOFTAC Database (Classic Collection).

It is listed as Case C.83: Wall-mounted two-dimensional hump with oscillatory zero-mass-flux jet or

suction through a slot (keyword: hump).

(Note that Case 3 was also a test case for the

11th ERCOFTAC/IAHR Workshop on

Refined Turbulence Modelling,

April 7-8, 2005, Chalmers Univ. of Technology,

Sweden, and a test case for the

12th ERCOFTAC/IAHR Workshop on Refined Turbulence Modelling, October 12-13, 2006,

Institute for Fluid Mechanics and Technical Acoustics,

Technical University of Berlin, Germany, and a test case for the

V&V I: Code Verification and Solution Verification & Validation Workshop at ECCOMAS CFD 2010,

June 14-17, 2010, Lisbon, Portugal.)

The characteristic reference length of the model is defined here as the

length of the bump on the wall, 16.536 inches. (In Seifert & Pack's

original work on the hump model, the reference length was defined as

the airfoil chord length of 7.874 inches (x = 0.0 to x = 7.874 inches).

Their leading edge was then faired smoothly into the wall from x = -.3937

to x = .3937 inches; however this additional length ahead of x = 0.0 was not

accounted for in their definition of the reference length. For the current

experiment it was felt to be more straightforward to use the actual bump

length as the reference length. As a result

of this, the current scaled (nondimensional) coordinates of the overall body

shape are slightly different from those of Seifert & Pack. A simple rescaling

operation can recover it.)

The model itself

is 23 inches wide between the endplates at both sides (each endplate is approximately

9.25 inches high, 34 inches long, and 0.5 inches thick with an elliptical-shaped

leading edge). The model is 2.116 inches

high at its maximum thickness point. Both uncontrolled (baseline)

and controlled flow scenarios are considered under the conditions

of M = 0.1 and Re somewhat less than 1 million

per chord. The tunnel medium is air at sea level. The model

experiences a fully-developed turbulent boundary layer whose delta

(thickness) at the leading edge of the model is between 1 - 2 inches.

The boundary

layer is subjected to a favorable pressure gradient over the front

convex portion of the body and separates over a relatively short

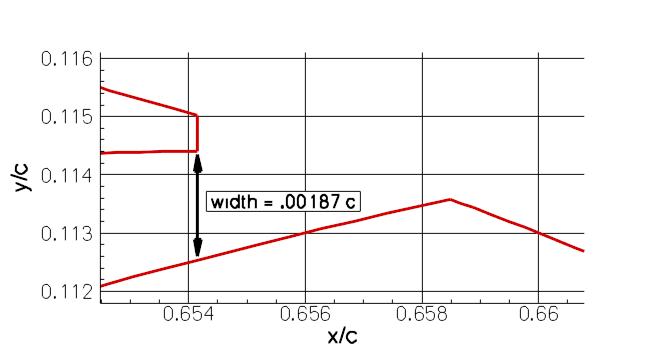

concave section in the aft part of the body. A slot opening of 0.00187*chord

(chord=0.4200 m) at approximately

the 65% chord station on the model extends across the entire span of

the hump ("slot opening" here means vertical opening below the lip - see figure

below).

Flow control is supplied by means of the

two-dimensional slot across the span, immediately upstream of the

concave surface. One type of control uses steady suction, which

is driven by a suction pump with the mass flow monitored.

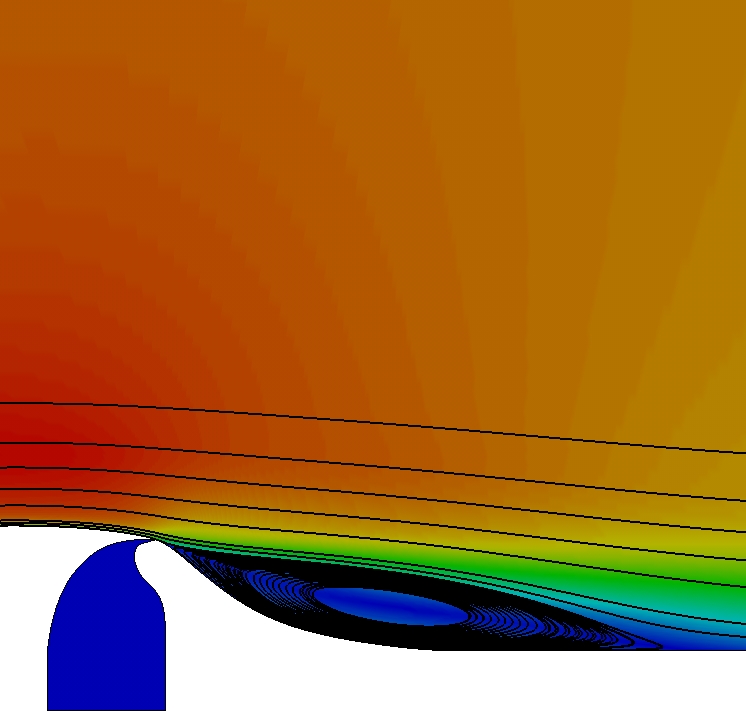

The following two figures show a schematic of the hump model

and a sample 2-D CFD result.

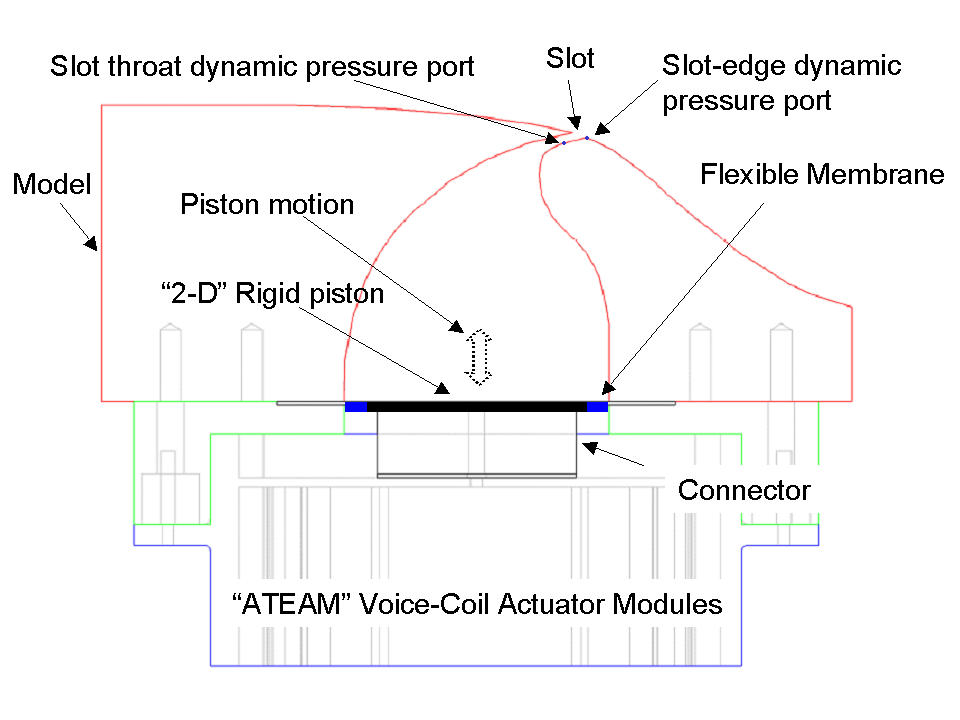

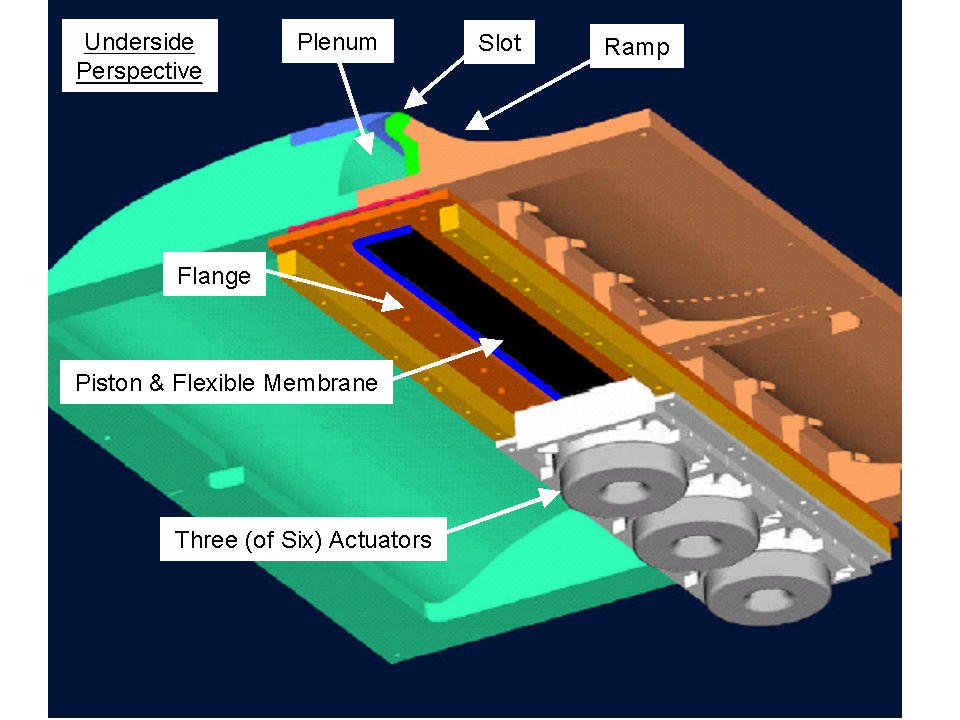

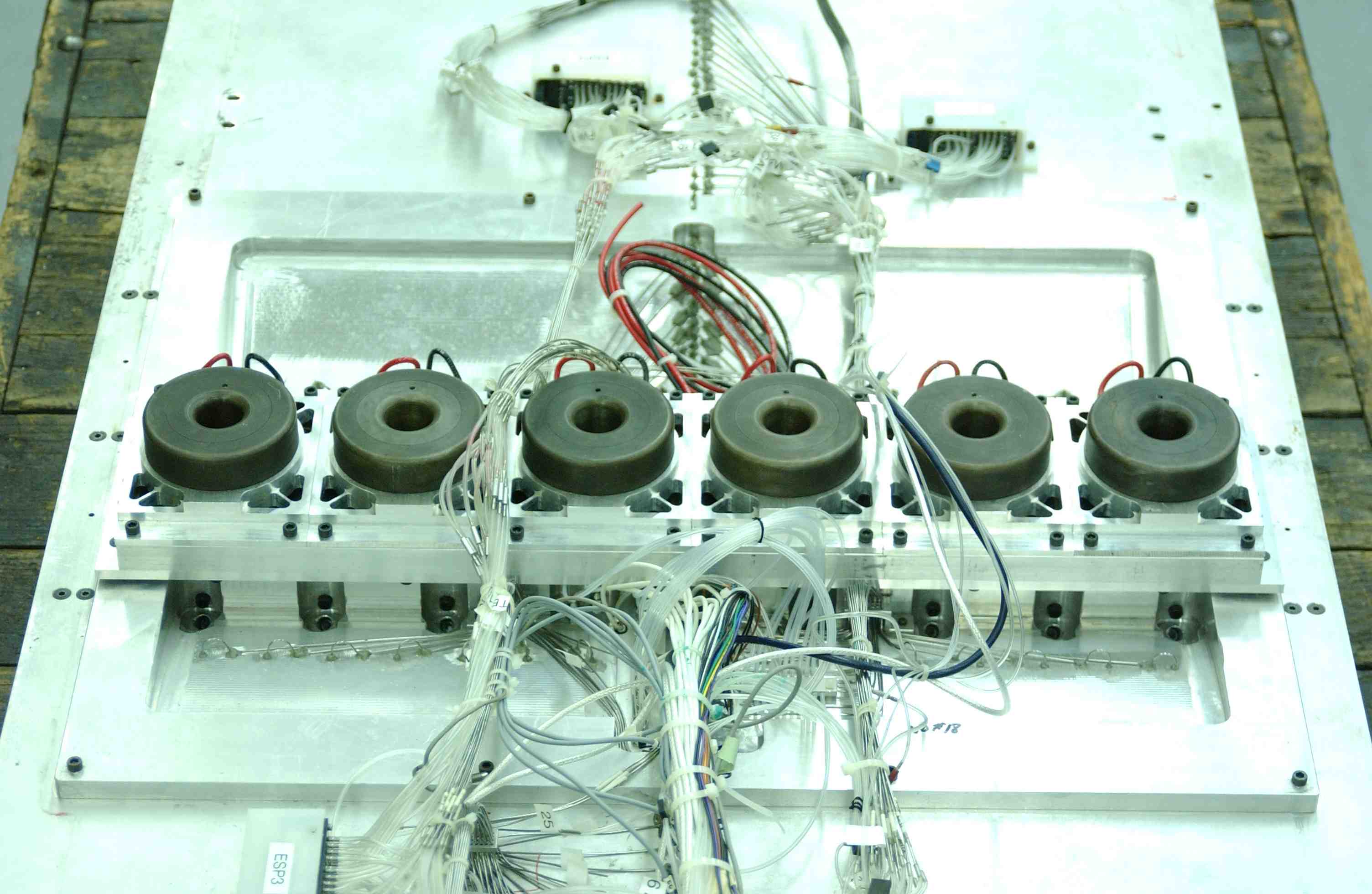

For the oscillatory test, separation control is performed using zero efflux oscillatory

blowing introduced from the spanwise slot, where careful attention is paid to

maintaining slot two-dimensionality. This is achieved by means of a rigid piston that

spans the model. The piston is secured to a flange by means of a flexible membrane

and the flange is bolted to the base of the plenum. The piston is driven externally by

six voice-coil-based actuator modules (Kiedaisch, Nagib and Associates, IIT), generating

slot velocities up to 80m/s at frequencies ranging from 60Hz to 500Hz. A schematic view

of the assembly from the side is shown in fig. 1 below; a view

from the underside of the model, with three modules removed for

purposes of illustrating the piston and membrane, is show in fig. 2. A photograph of the

underside of the model, prior to tunnel installation, is shown in fig. 3. The slot-flow

is calibrated and characterized for both tunnel flow-off (quiescent) and flow-on

(non-quiescent) conditions, using hot-wire anemometry, throat dynamic pressure

measurements and two-dimensional PIV.

Fig. 1 Fig. 2 Fig. 3

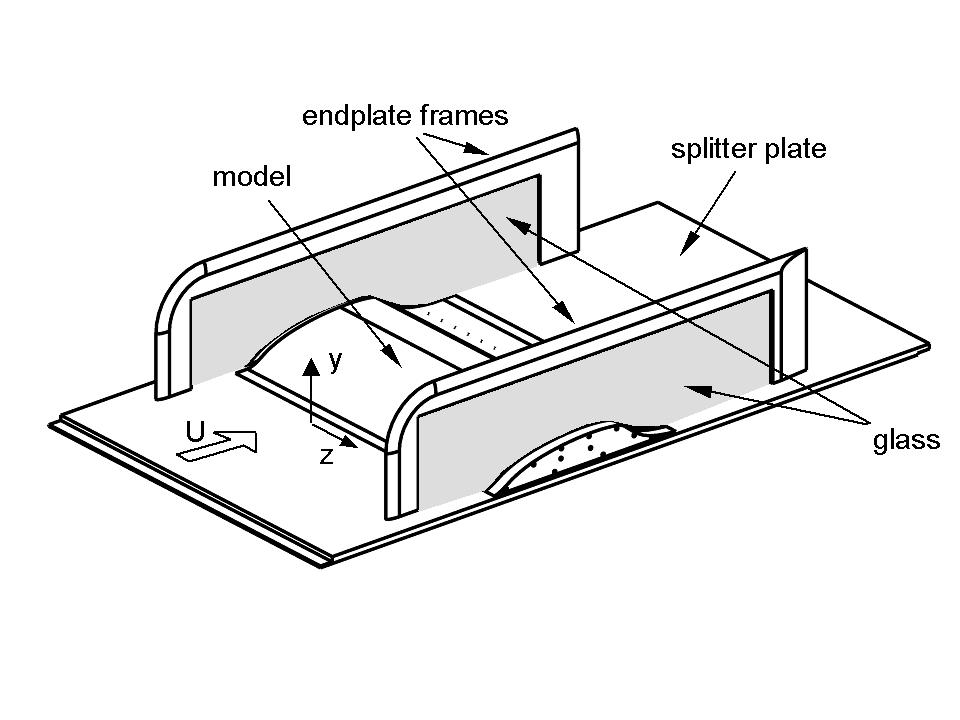

Case 3 is a Wall-mounted Glauert-Goldschmied type body, geometrically

similar to that employed by Seifert & Pack (2002). Full details of the current case

are given in Greenblatt et al (2004, 2005) and Naughton et al (2004). The model is

mounted between two glass endplate frames and both leading edge and trailing

edges are faired smoothly with a wind tunnel splitter plate. This is a

nominally two-dimensional experiment, although there are side-wall

effects (3-D flow) near the end-plates. The tunnel dimensions at the

test section are 28 inches wide by 20 inches high, but the hump model is

mounted on a splitter plate (0.5 inches thick), yielding a nominal test section

height of 15.032 inches (distance from the splitter plate to the top wall).

The splitter plate extends 76.188 inches upstream of the model's leading

edge. Also, 44.437 inches downstream of the model's leading edge,

the splitter plate is equipped with a flap (3.75 inches long), which

is deflected up during the experiment in order to control the air flow

beneath the splitter plate. This control affects the stagnation point

at the leading edge of the splitter plate, avoiding massive separation

in that region.

Note that the two endplate frames create blockage which affects all the measurements for this case. See "Experimantalist's Note 3", in the Experimental Data link below. Also, one of the questions in the FAQS link below addresses this issue.

References:

Return to: CFDVAL2004 - Intro Page

Return to: Data from Experiments - Intro Page Return to: Turbulence Modeling Resource Home Page

Responsible NASA Official:

Ethan Vogel

Page Curator:

Clark Pederson

Last Updated: 11/04/2021