Results are shown here from 2 compressible codes

so that the user may compare their own compressible code results. Multiple grids were

used so the user can see trends with grid refinement. Different codes will behave

differently with grid refinement depending on many factors (including code order of accuracy

and other numerics),

but it would be expected that as the grid is refined the results

will tend toward an "infinite grid" solution that is the same.

Be careful when comparing details: any differences in boundary conditions or flow conditions

may affect results.

Two independent compressible RANS codes,

CFL3D and FUN3D, were used to compute this

bump-in-channel flow with the Spalart-Allmaras turbulence model

(version SA-QCR2013-V - see full description on

Spalart-Allmaras page).

The full series of 5 grids were used.

CFL3D is a cell-centered structured-grid code, and FUN3D is a

node-centered unstructured-grid code (it can solve on mixed element grids, so this case

was computed on the same hexahedral grid used by CFL3D).

Both codes were run with full Navier-Stokes,

and both codes used first-order upwinding for the advective terms of the turbulence model.

Details about the codes can be found on their respective websites,

the links for which are given on this site's

home page.

The codes were not run to machine-zero iterative convergence, but an attempt was made to converge

sufficiently so that results of interest were well within normal engineering tolerance and

plotting accuracy. For example, for CFL3D the density residual was typically

driven down below 10-13. It should be kept in mind that many of the files given below

contain computed values directly from the codes,

using a precision greater than the convergence tolerance (i.e., the values

in the files are not necessarily as precise as the number of digits given).

The main reason for implementing QCR2013-V (rather than QCR2013), is because

in current experience, the mut*sqrt(2*Smn*Smn)

term in the QCR2013 model can sometimes cause numerical

problems. See description of QCR2013-V on the Spalart-Allmaras page).

It should be noted that the QCR2013-V correction has relatively minor effect in this case,

but the influence is detectable (compared to SA) as the grid is refined.

However, the differences between

SA-QCR2000,

SA-QCR2013, and SA-QCR2013-V are generally negligible.

The SA results alone can also be found on the page:

SA Expected Results - 2D Bump-in-channel.

For the CFL3D and FUN3D tests reported below, the turbulent inflow boundary condition used for SA was:

.

For the interested reader, typical input files for this problem are given here:

.

For the interested reader, typical input files for this problem are given here:

CFL3D:

FUN3D:

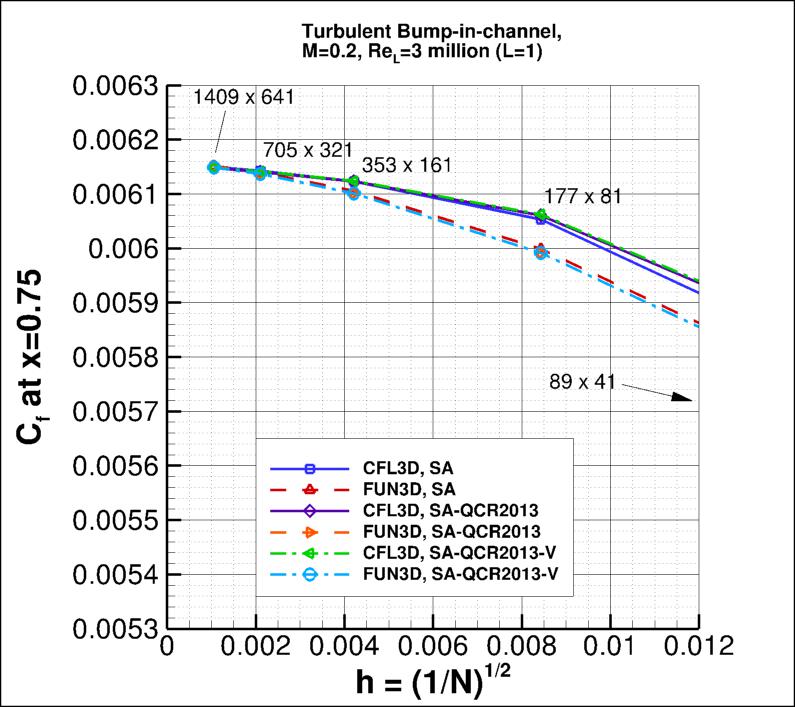

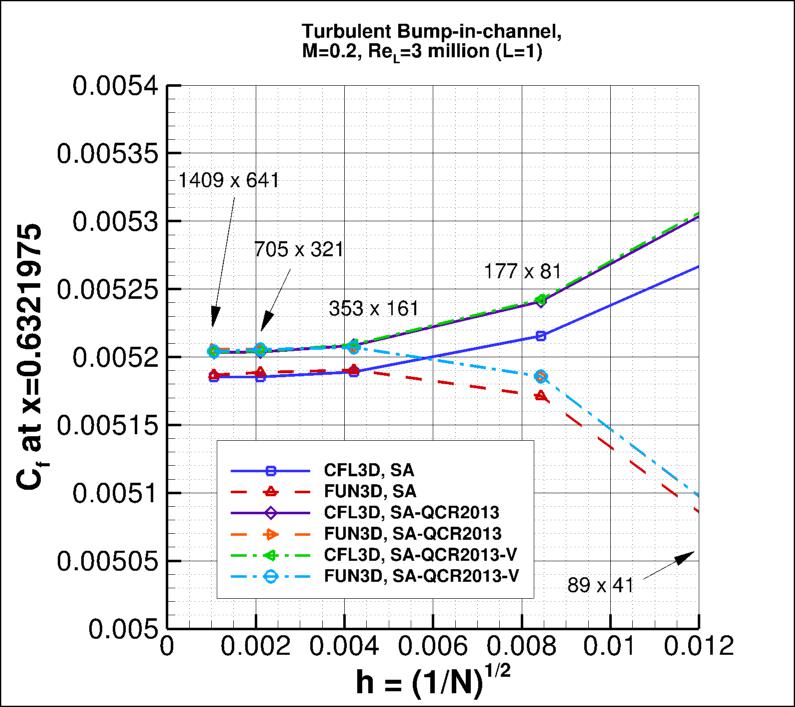

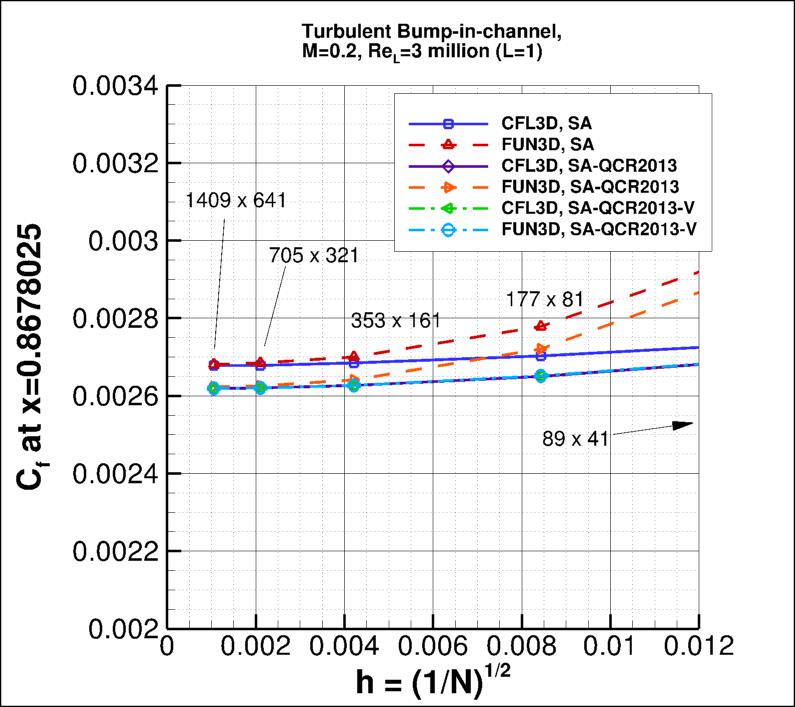

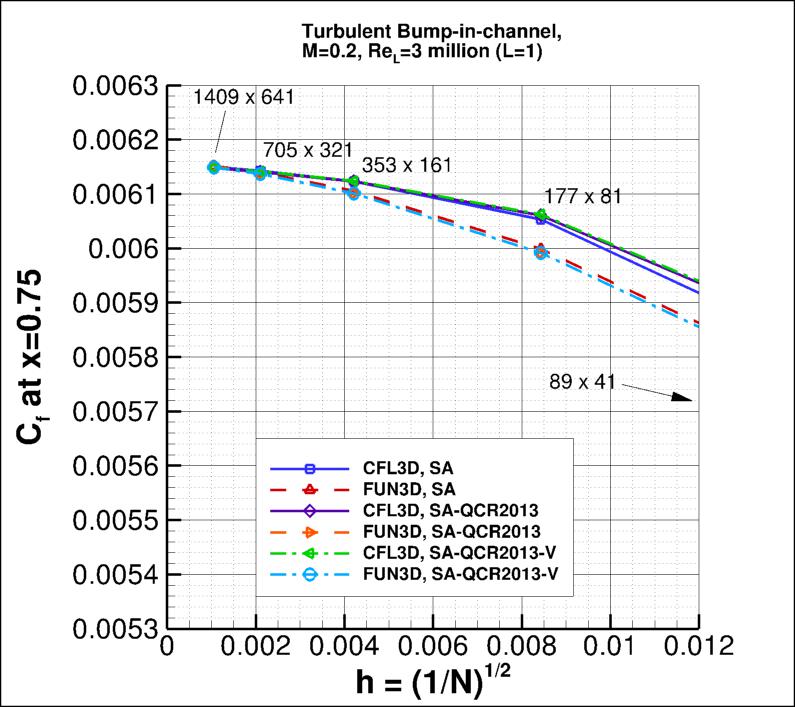

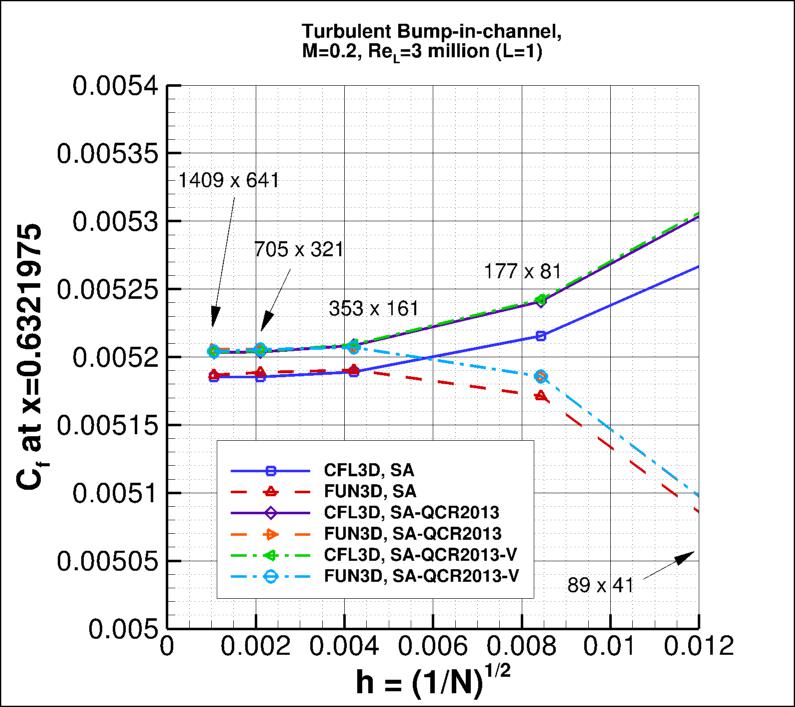

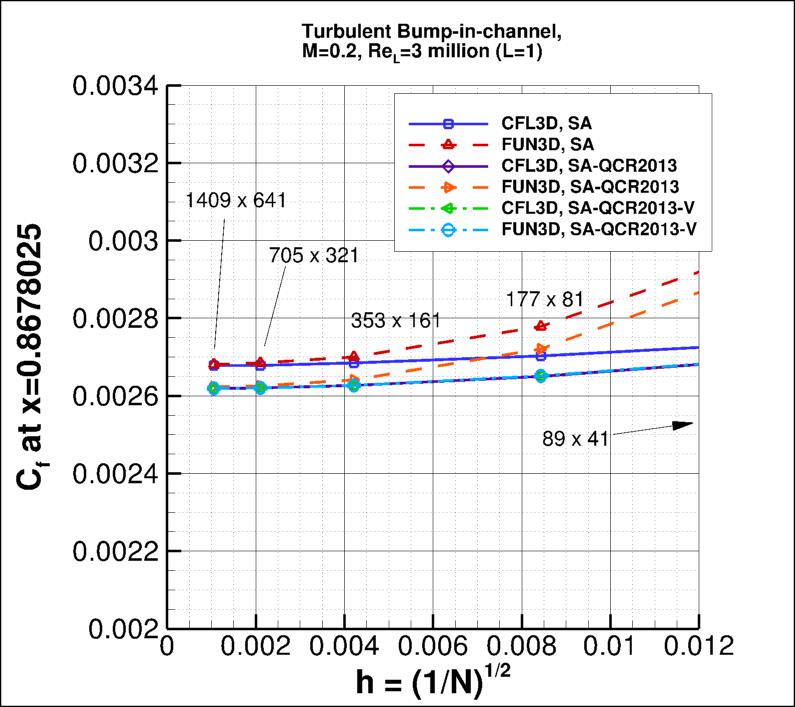

The following plots show the convergence of the wall skin friction coefficient

at the bump peak (at x=0.75), in front of the bump peak (at x=0.6321975), and

aft of the peak (at x=0.8678025) with

grid size for the three codes.

The plots show results for SA, SA-QCR2013, and SA-QCR2013-V so that the results can be compared.

SA-QCR2013 and SA-QCR2013-V are essentially indistinguishable, whereas they are slightly different

from SA as the grid is refined.

In the plot the x-axis is plotting 1/N1/2, which is proportional to

grid spacing (h).

At the left of the plot, h=0 represents an infinitely fine grid.

Both codes go toward approximately the same result on an infinitely refined grid.

Using the uncertainty estimation procedure from the Fluids Engineering Division of the ASME (Celik, I. B.,

Ghia, U., Roache, P. J., Freitas, C. J., Coleman, H., Raad, P. E.,

"Procedure for Estimation and Reporting of Uncertainty Due

to Discretization in CFD Applications," Journal of Fluids Engineering, Vol. 130, July 2008, 078001, https://doi.org/10.1115/1.2960953), described in Summary of Uncertainty Procedure,

the finest 3 grids yield the following for skin friction coefficient at x=0.75, x=0.6321975, and

x=0.8678025 for SA-QCR2013-V:

| Code |

Computed apparent order, p |

Approx rel fine-grid error, ea21 |

Extrap rel fine-grid error, eext21 |

Fine-grid convergence index, GCIfine21 |

| x=0.75 |

| CFL3D |

1.37 |

0.107% |

0.068% |

0.085% |

| FUN3D |

1.57 |

0.193% |

0.098% |

0.123% |

| x=0.6321975 |

| CFL3D |

3.45 |

0.009% |

0.001% |

0.135% |

| FUN3D |

0.10 |

0.028% |

0.387% |

0.073% |

| x=0.8678025 |

| CFL3D |

2.28 |

0.052% |

0.014% |

0.017% |

| FUN3D |

1.72 |

0.173% |

0.075% |

0.094% |

The data file that generated the above plot is given here:

cf_convergence_saqcr2013v_75.dat,

cf_convergence_saqcr2013v_632.dat, and

cf_convergence_saqcr2013v_868.dat.

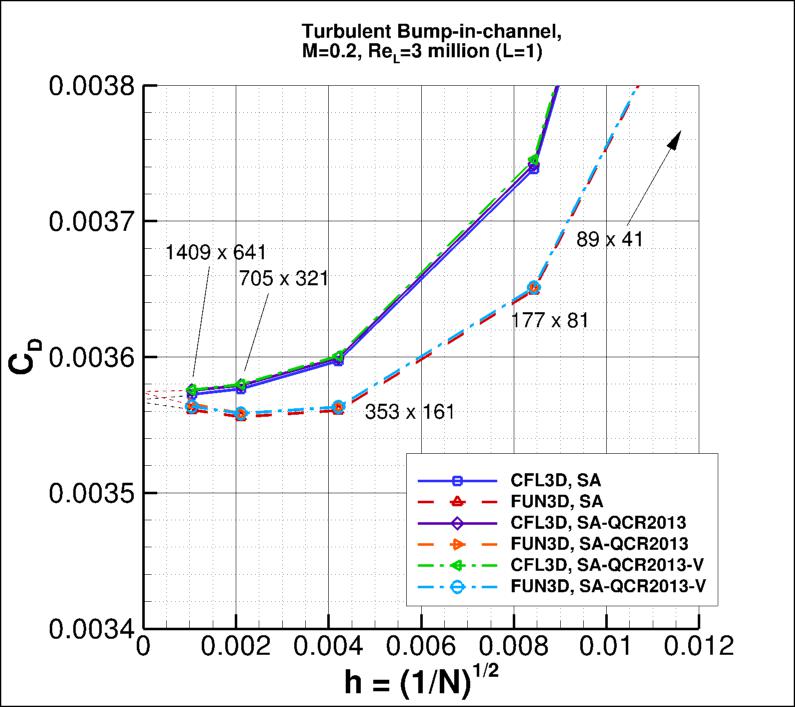

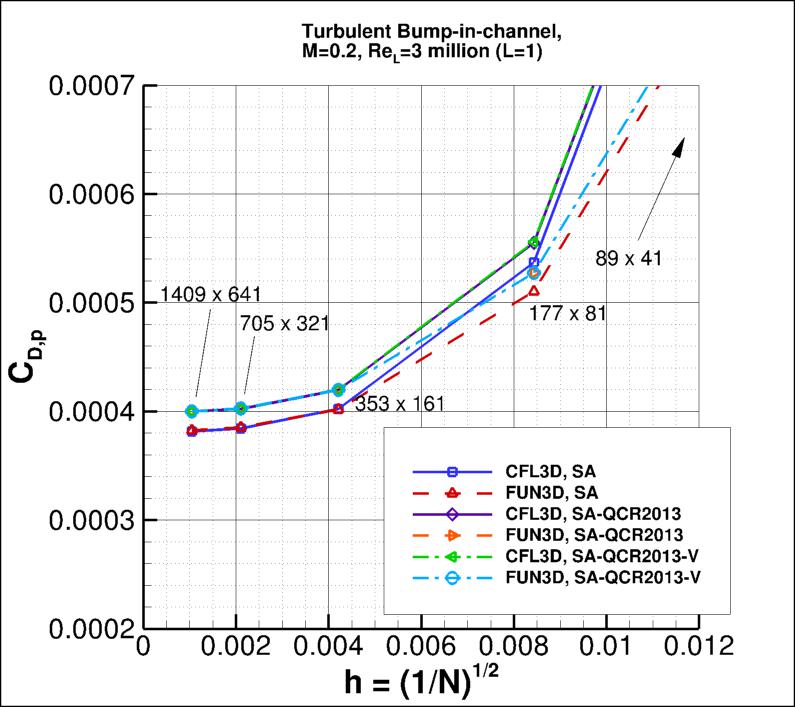

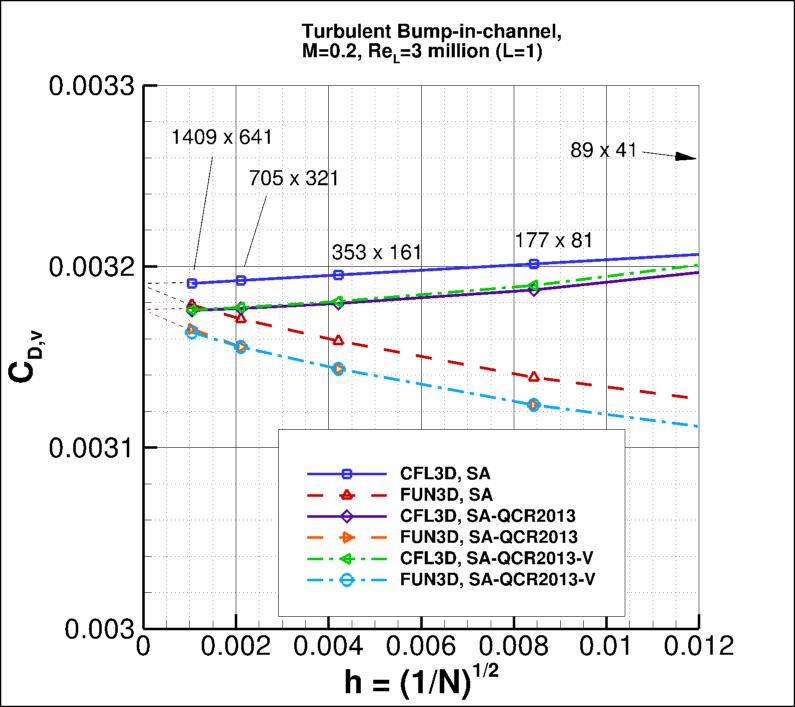

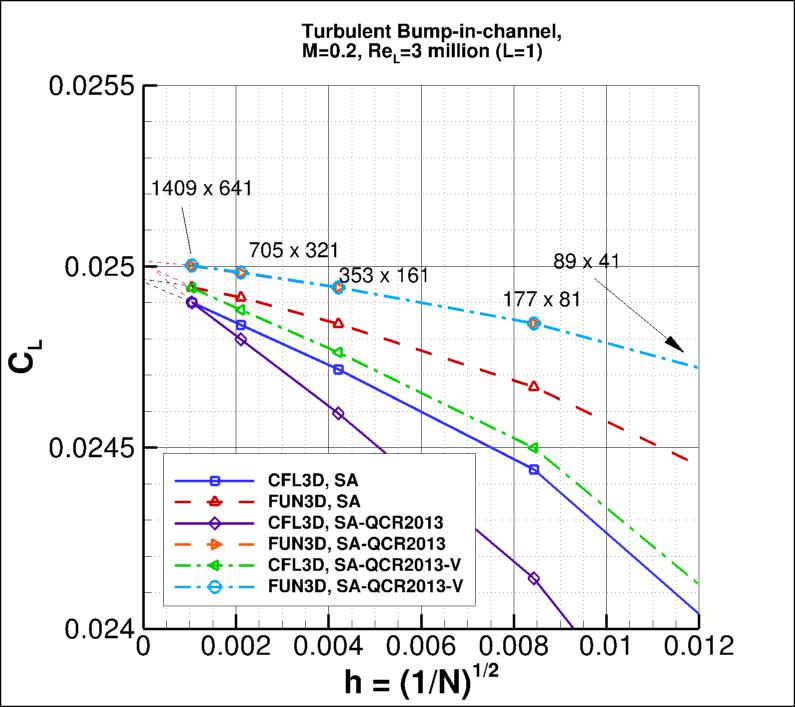

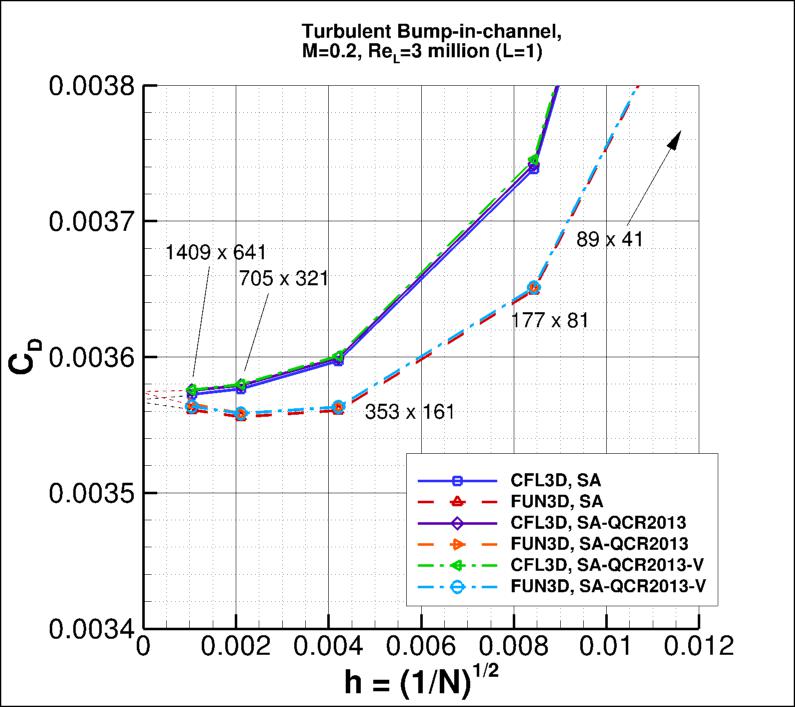

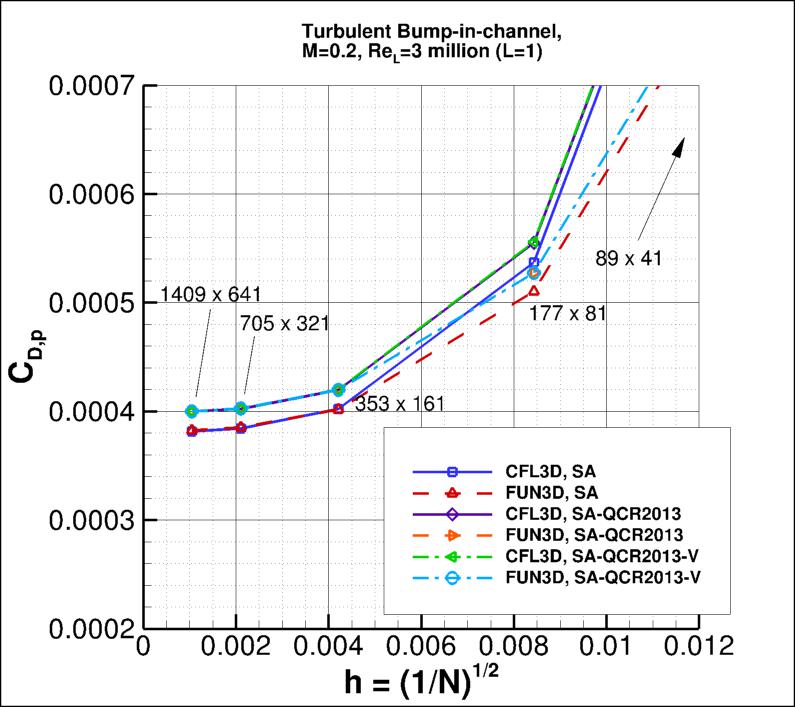

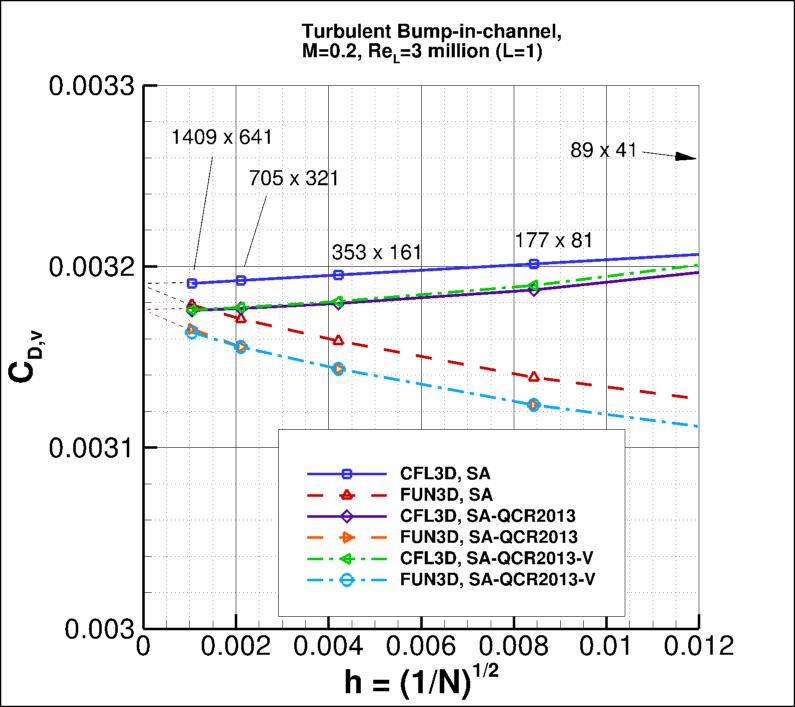

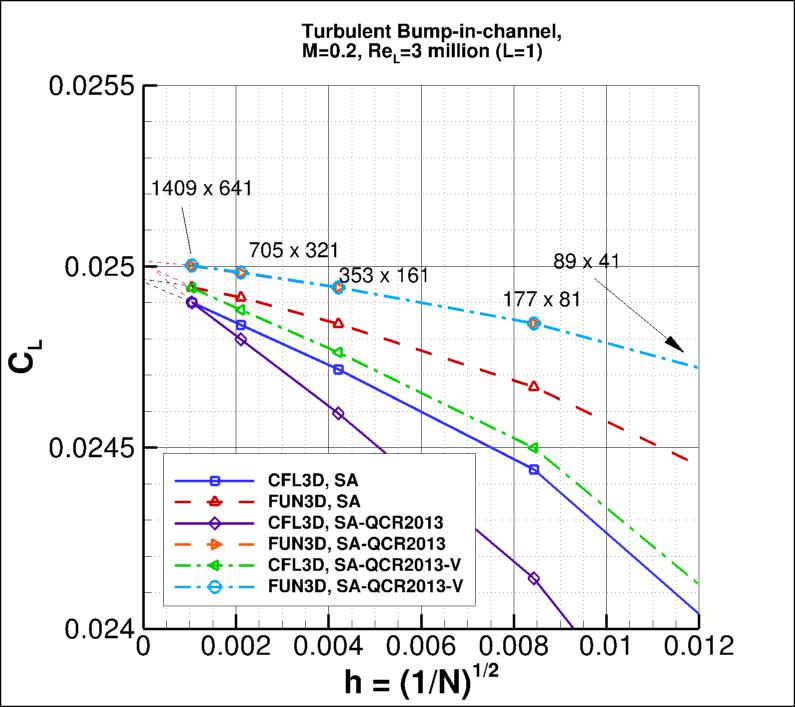

The following plots show: (1) total drag coefficient, (2) pressure drag coefficient,

(3) viscous drag coefficient, and (4) total lift coefficient for the bump.

In this bump case the surface skin friction

is singular (tends toward infinity) at the leading edge. The finer the grid, the more nearly singular

the local behavior on a finite grid.

There is also locally anomalous behavior in Cf at the back end of the bump wall (at x=1.5), as

is often seen in CFD solutions near trailing edges (see, e.g., Swanson and Turkel, AIAA Paper 87-1107, 1987

https://doi.org/10.2514/6.1987-1107).

Both of these behaviors may have some influence

on the convergence/order-property of the integrated viscous component of the drag coefficient.

As seen in the following plots, both codes are tending toward similar integrated force coefficient values

as the grid is refined.

Using the uncertainty estimation procedure from the Fluids Engineering Division of the ASME (Celik, I. B.,

Ghia, U., Roache, P. J., Freitas, C. J., Coleman, H., Raad, P. E.,

"Procedure for Estimation and Reporting of Uncertainty Due

to Discretization in CFD Applications," Journal of Fluids Engineering, Vol. 130, July 2008, 078001, https://doi.org/10.1115/1.2960953), described in Summary of Uncertainty Procedure,

the finest 3 grids yield the following for force coefficients of SA-QCR2013-V:

| Code |

Quantity |

Computed apparent order, p |

Approx rel fine-grid error, ea21 |

Extrap rel fine-grid error, eext21 |

Fine-grid convergence index, GCIfine21 |

| CFL3D |

Cd |

2.43 |

0.110% |

0.025% |

0.031% |

| CFL3D |

Cd,p |

2.86 |

0.619% |

0.099% |

0.124% |

| CFL3D |

Cd,v |

1.16 |

0.046% |

0.037% |

0.046% |

| CFL3D |

CL |

0.97 |

0.240% |

0.248% |

0.311% |

| FUN3D |

Cd |

oscillatory convergence |

0.147% |

N/A |

N/A |

| FUN3D |

Cd,p |

2.59 |

0.698% |

0.139% |

0.174% |

| FUN3D |

Cd,v |

0.60 |

0.254% |

0.486% |

0.610% |

| FUN3D |

CL |

1.09 |

0.077% |

0.067% |

0.084% |

The data file that generated the above plot is given here:

force_convergence_saqcr2013v.dat.

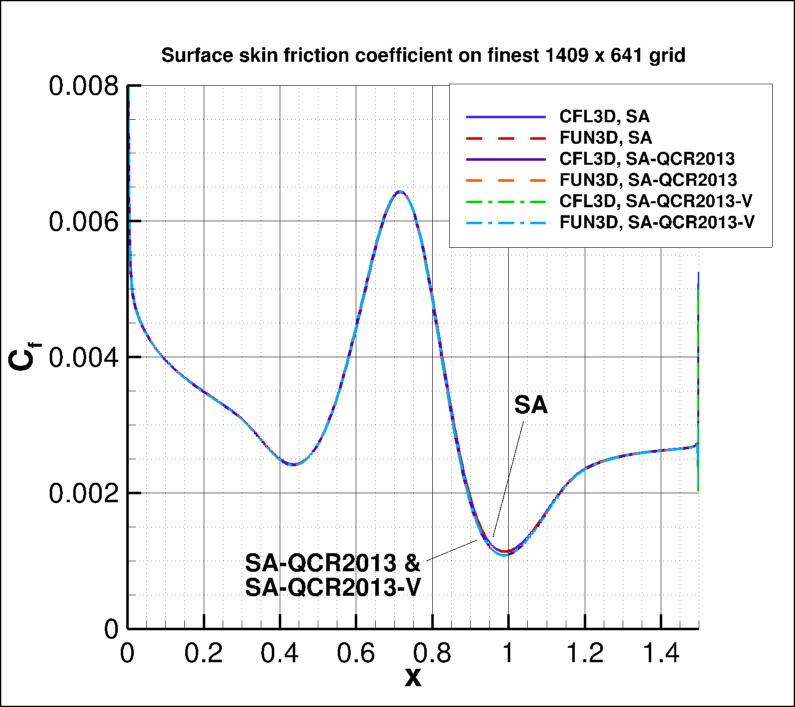

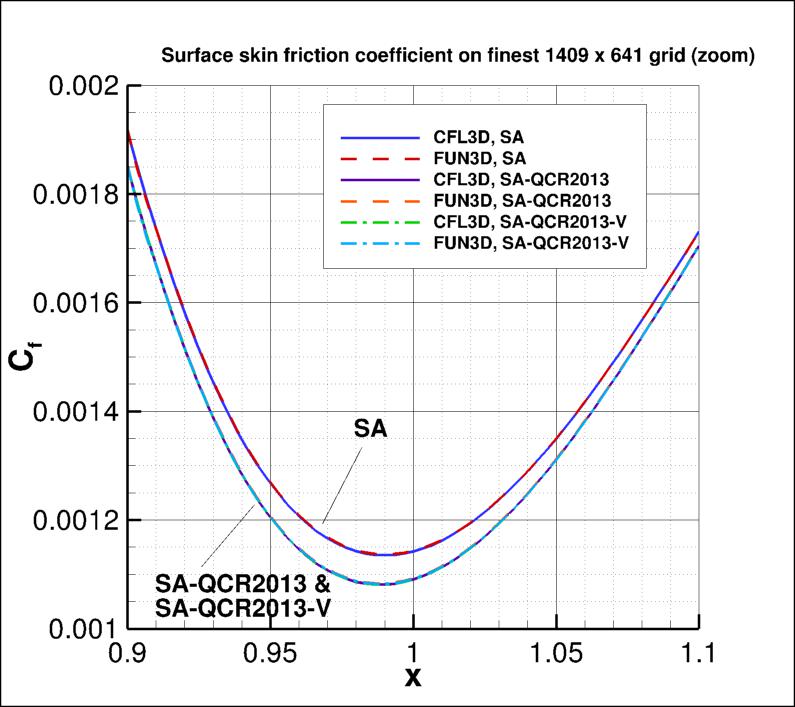

The surface skin friction coefficient from both codes on the finest 1409 x 641 grid

over the entire bump wall, as well as in a zoomed view,

is shown in the next two plots (for SA, SA-QCR2013, and SA-QCR2013-V).

Again, local anomalous behavior exists near the leading

edge (x=0) due to singular behavior of the solution,

as well as near the trailing edge (x=1.5) due to numerical influences.

These behaviors differ for the codes, and result in small local deviations that

can be seen when zoomed into the two locations. But both codes are seen to yield nearly identical results

over most of the bump wall.

The data file that generated the above plots is given here:

cf_bump_saqcr2013v.dat.

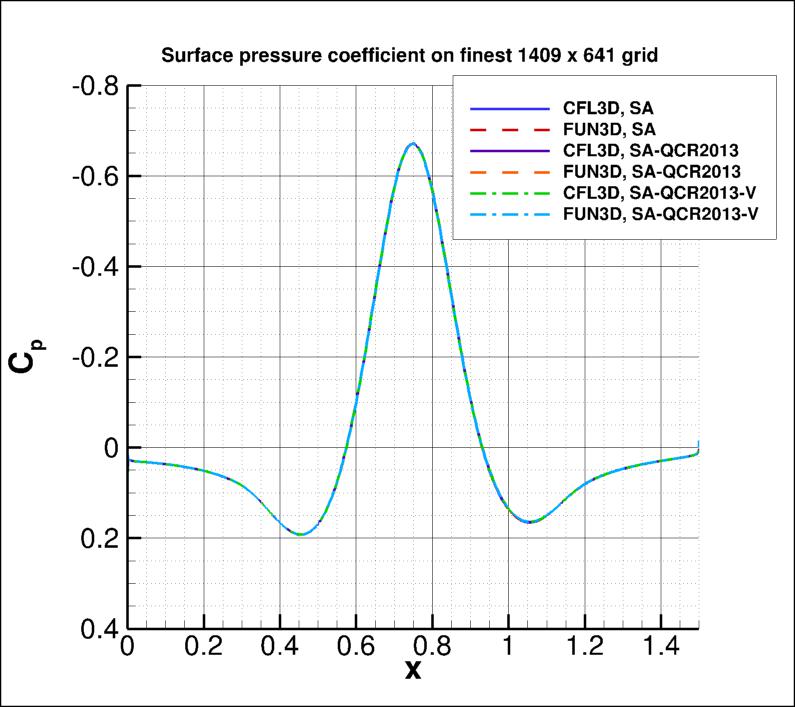

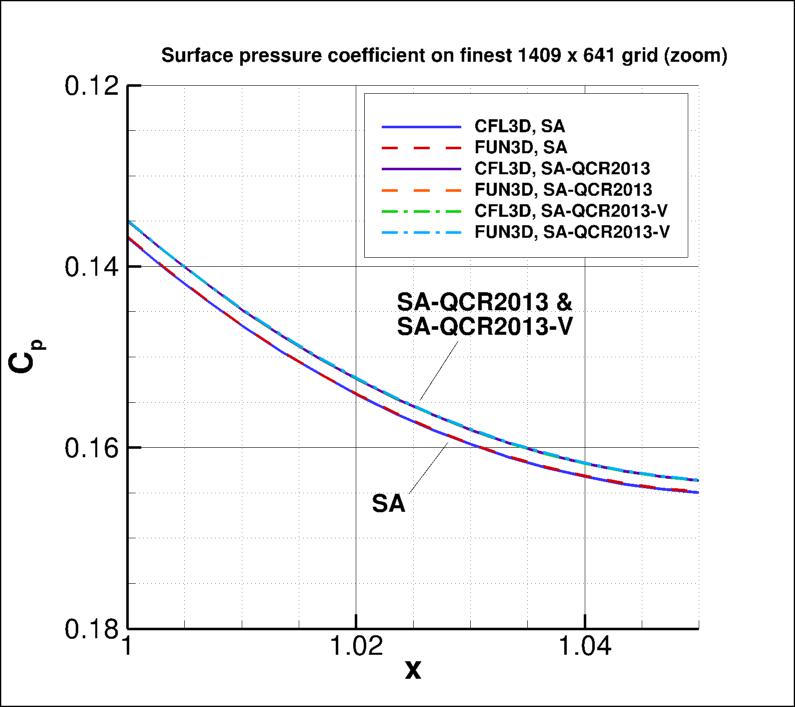

The surface pressure coefficient from both codes on the finest 1409 x 641 grid

over the entire bump wall is shown in the next plot.

Both codes yield nearly identical results, and there is essentially no difference between

SA-QCR2013 and SA-QCR2013-V (and very little difference between these models and SA).

One area of minor differences between the models is highlighted in the second zoomed-in plot.

The data file that generated the above plots is given here:

cp_bump_saqcr2013v.dat.

Like most of the quantities shown above, the eddy viscosity and

velocity profiles from SA-QCR2013-V are essentially identical to results from

SA-QCR2013, so they are not shown here. See the

SA-QCR2013 page instead.

The main advantage to employing the quadratic constitutive relation (QCR) in SA-QCR2013-V

is that it better represents

the turbulent normal stress differences in boundary layers. These have very little effect for this case,

but may be important in some situations (for example, when computing flow near corners).

For details about the normal stress differences that result from QCR2013, please refer to the

SA-QCR2013 Expected Results - 2D Zero Pressure Gradient Flat Plate or the

SA-RC-QCR2013 Expected Results - 2D Zero Pressure Gradient Flat Plate page.

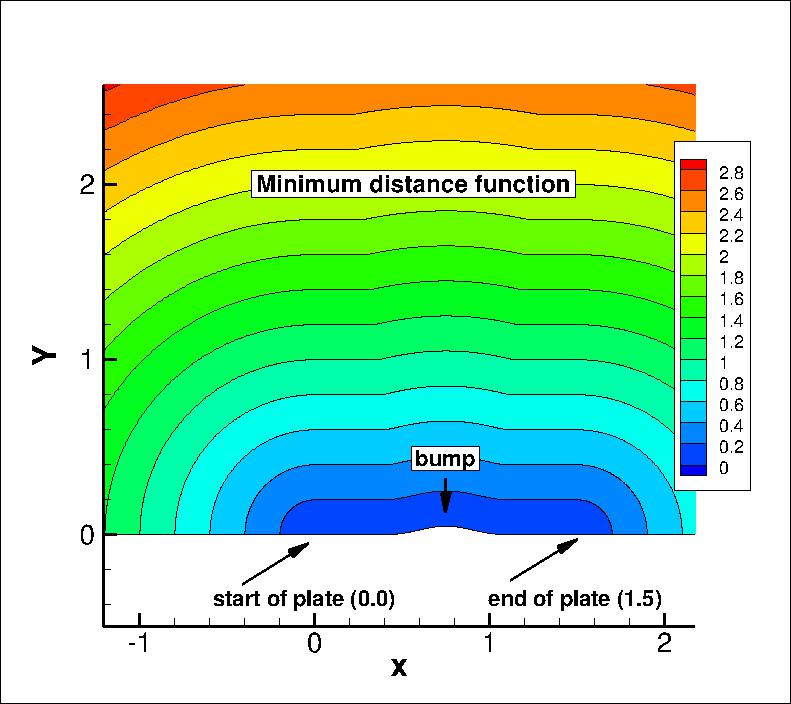

The SA model relies on the minimum distance to the nearest wall. For this case,

contours of this function

are shown in the following plot, for the grid 1 level down from the finest

grid.

The data file that generated the above plot is given in

bump_1levdown.mindist.dat.gz (gzipped file,

3.9 MB, unstructured, at grid points). Note

that this is a gzipped Tecplot

formatted file, so you must either have Tecplot or know how to read their format in

order to use it.

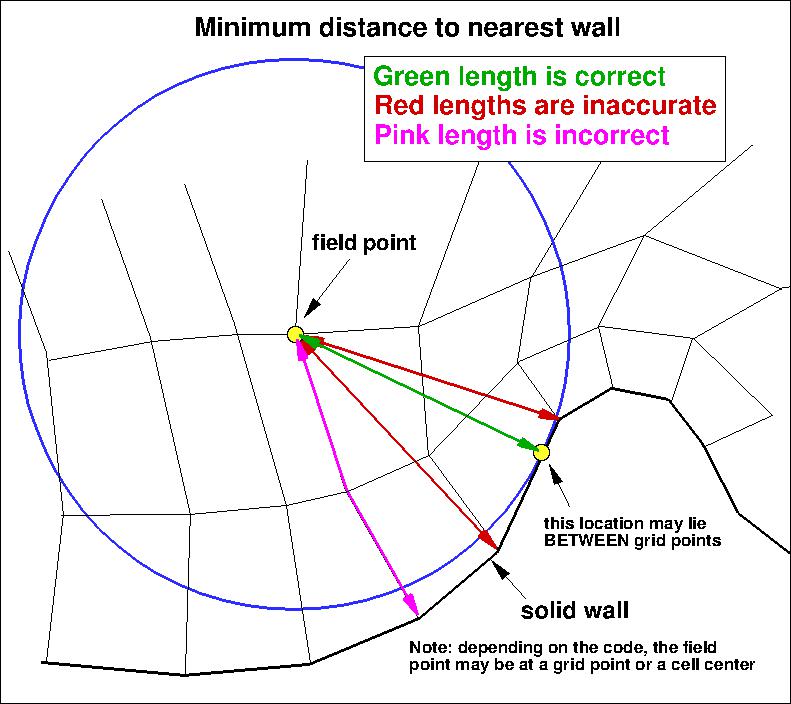

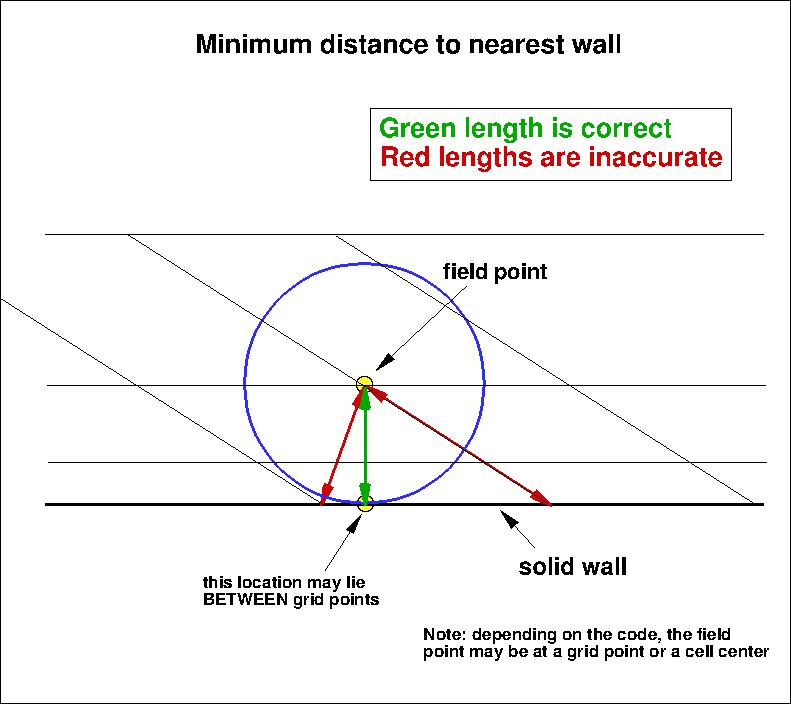

It is important to note that computing minimum distance by searching along grid lines is

incorrect, and is not the same as computing actual minimum distance to the nearest wall for this grid. Using

the former method will yield some minor differences in the results. The following sketches

demonstrate the concept of minimum distance. Improperly-calculated minimum distance

functions will particularly produce incorrect results for cases in which the

grid lines are not perfectly normal to the body surface.

Note that when the nearest wall point is a sharp convex corner or edge (like an airfoil or wing trailing edge) then the

correct minimum distance is the distance to that corner or edge, which is not a wall normal.

Return to: 2D Bump-in-channel Verification Case Intro Page

Return to: Turbulence Modeling Resource Home Page

Privacy Act Statement

Accessibility Statement

Responsible NASA Official:

Ethan Vogel

Page Curator:

Clark Pederson

Last Updated: 03/01/2023

.

For the interested reader, typical input files for this problem are given here:

.

For the interested reader, typical input files for this problem are given here: