Results are shown here from 2 compressible codes

so that the user may compare their own compressible code results. Multiple grids were

used so the user can see trends with grid refinement. Different codes will behave

differently with grid refinement depending on many factors (including code order of accuracy

and other numerics),

but it would be expected that as the grid is refined the results

will tend toward an "infinite grid" solution that is the same.

Be careful when comparing details: any differences in boundary conditions or flow conditions

may affect results.

Two independent compressible RANS codes,

CFL3D and FUN3D, were used to compute this

zero-pressure-gradient flat plate flow with the Spalart-Allmaras turbulence model

(version SA-QCR2000 - see full description on

Spalart-Allmaras page). The full series of 5 grids were used.

CFL3D is a cell-centered structured-grid code, and FUN3D is a

node-centered unstructured-grid code (it can solve on mixed element grids, so this case

was computed on hexahedral grids).

Both codes were run with full Navier-Stokes.

and both used first-order upwinding for the advective terms of the turbulence model.

The codes were run to nearly machine-zero iterative convergence, so

results of interest were well within normal engineering tolerance and

plotting accuracy.

It should be noted that the QCR2000 correction has very little effect in this case,

but the influence is detectable (compared to SA) as the grid is refined.

For the CFL3D and FUN3D tests reported below, the turbulent inflow boundary condition used for SA-QCR2000 was:

.

For the interested reader, typical input files for this problem are given here:

.

For the interested reader, typical input files for this problem are given here:

CFL3D:

FUN3D:

Most of the following SA-QCR2000 results are plotted below against standard SA results, for comparison.

Note that the CFL3D and FUN3D SA results are from the

SA Expected Results page, and were run many years ago (CFL3D V6.5 and FUN3D rev 32421).

However, the grid-converged solutions have not changed.

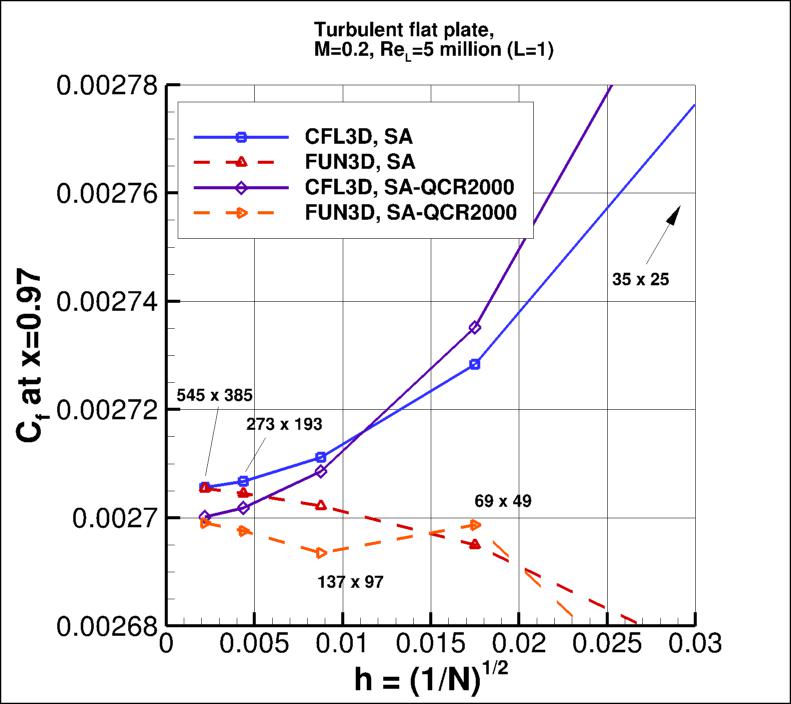

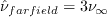

The following plot shows the convergence of the wall skin friction coefficient at x=0.97008 with

grid size for both codes, for both SA and SA-QCR2000.

In the plot, the x-axis is plotting 1/N1/2, which is proportional to

grid spacing (h).

At the left of the plot, h=0 represents an infinitely fine grid.

As can be seen, the two codes agree well as the grid is refined. Also, there is

very little difference between SA and SA-QCR2000, but it is a consistent difference

on the finer grids.

SA-QCR2000 yields a slightly lower level of grid-converged skin friction at this location.

Using the uncertainty estimation procedure from the Fluids Engineering Division of the ASME (Celik, I. B.,

Ghia, U., Roache, P. J., Freitas, C. J., Coleman, H., Raad, P. E.,

"Procedure for Estimation and Reporting of Uncertainty Due

to Discretization in CFD Applications," Journal of Fluids Engineering, Vol. 130, July 2008, 078001, https://doi.org/10.1115/1.2960953), described in Summary of Uncertainty Procedure,

the finest 3 grids yield the following for skin friction coefficient for SA-QCR2000 at x=0.97:

| Code |

Computed apparent order, p |

Approx rel fine-grid error, ea21 |

Extrap rel fine-grid error, eext21 |

Fine-grid convergence index, GCIfine21 |

| CFL3D |

2.01 |

0.062% |

0.020% |

0.026% |

| FUN3D |

1.41 |

0.056% |

0.034% |

0.042% |

The data file that generated the above plot is given here:

cf_convergence_saqcr.dat.

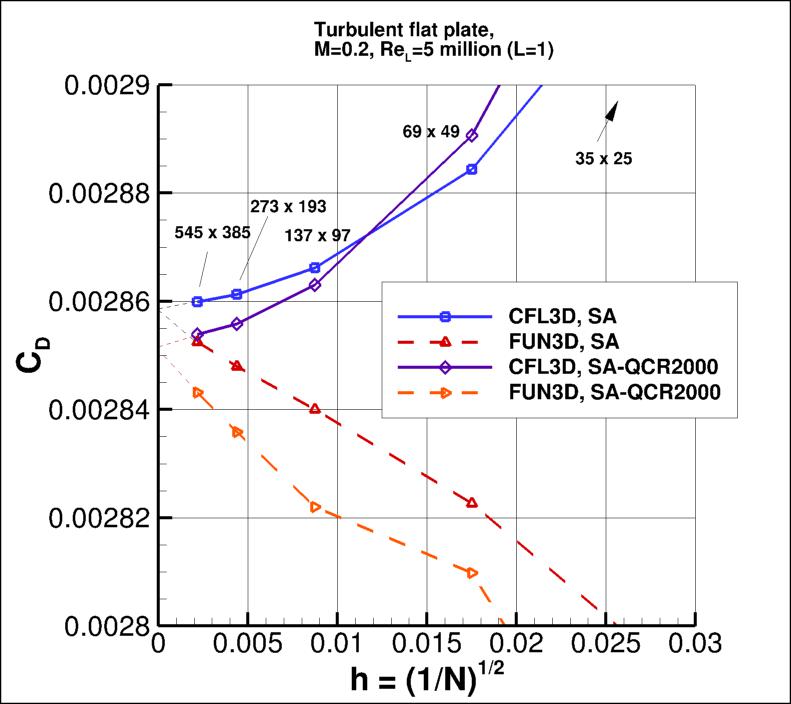

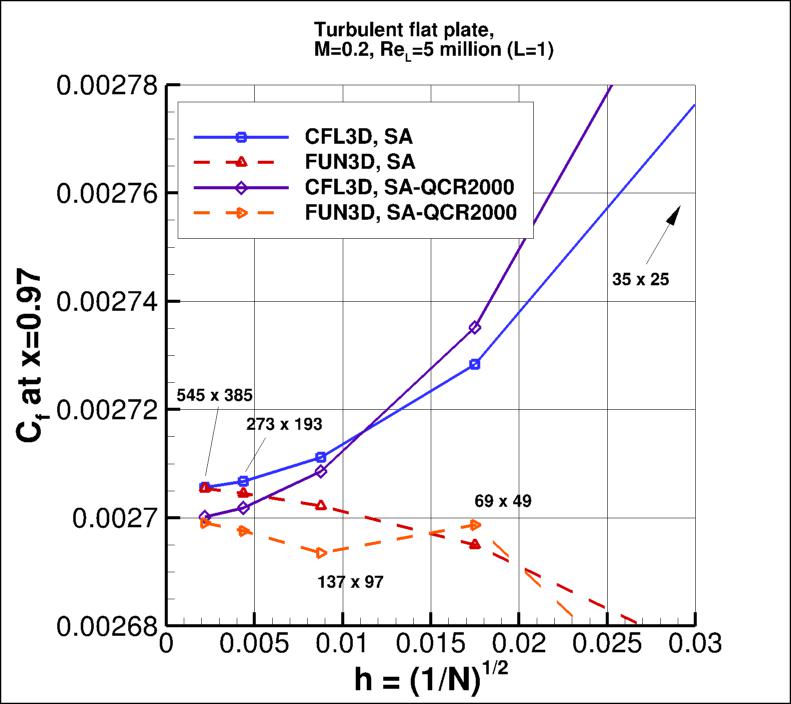

Note that in this particular flat plate case, when looking at the total integrated drag coefficient on the plate,

formal order-property convergence may not be generally achievable. This is because the skin friction

(which is the only contributor to the drag in this case)

is singular (tends toward infinity) at the leading edge. The finer the grid, the more nearly singular

the local behavior on a finite grid.

There also appears to be some locally minor

anomalous behavior at the aft end of the plate, which is likely a function of

how each code handles the interaction of the solid wall boundary condition with the

outflow pressure boundary condition near the bottom right corner of the grid.

Nonetheless, both codes are tending toward a similar integrated drag coefficient value

as the grid is refined, and SA-QCR2000 yields slightly lower grid-converged drag values than SA as the grid is refined.

Using the uncertainty estimation procedure from the Fluids Engineering Division of the ASME (Celik, I. B.,

Ghia, U., Roache, P. J., Freitas, C. J., Coleman, H., Raad, P. E.,

"Procedure for Estimation and Reporting of Uncertainty Due

to Discretization in CFD Applications," Journal of Fluids Engineering, Vol. 130, July 2008, 078001, https://doi.org/10.1115/1.2960953), described in Summary of Uncertainty Procedure,

the finest 3 grids yield the following for drag coefficient for SA-QCR2000:

| Code |

Computed apparent order, p |

Approx rel fine-grid error, ea21 |

Extrap rel fine-grid error, eext21 |

Fine-grid convergence index, GCIfine21 |

| CFL3D |

1.85 |

0.070% |

0.027% |

0.033% |

| FUN3D |

0.94 |

0.255% |

0.279% |

0.350% |

The data file that generated the above plot is given here:

drag_convergence_saqcr.dat.

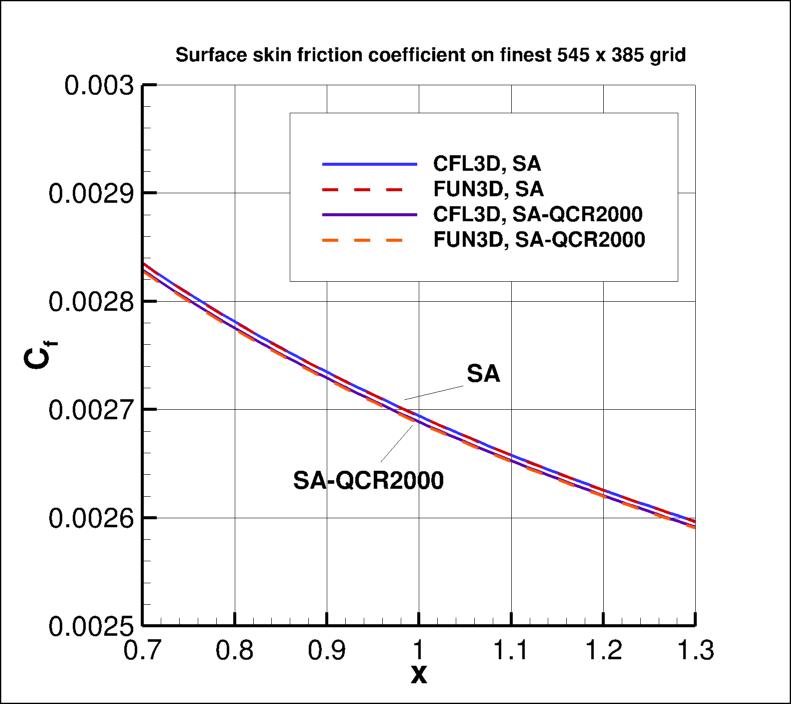

The surface skin friction coefficient from both codes on the finest 545 x 385 grid

over a portion of the plate is shown in the next plot. Again, local anomalous behavior exists near the leading

edge (x=0) due to singular behavior of the solution,

and near the trailing edge (x=2) most likely due to boundary condition

interaction. These behaviors differ for the codes, and result in small local deviations that

can be seen when zoomed into the two locations. But the codes are seen to yield nearly the same results

over most of the plate, and the SA-QCR2000 is clearly slighty lower than SA.

The data file that generated the above plot is given here:

cf_plate_saqcr.dat.

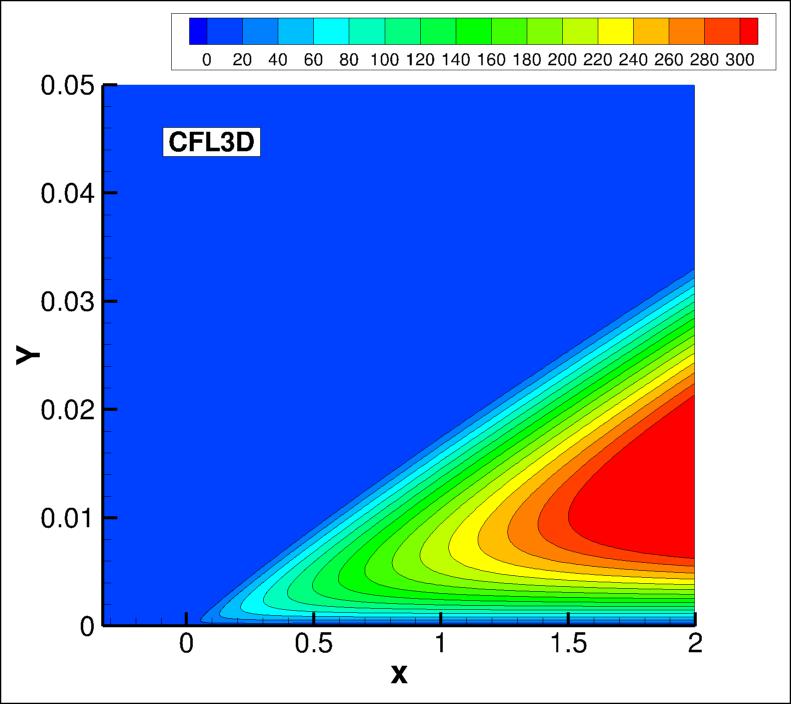

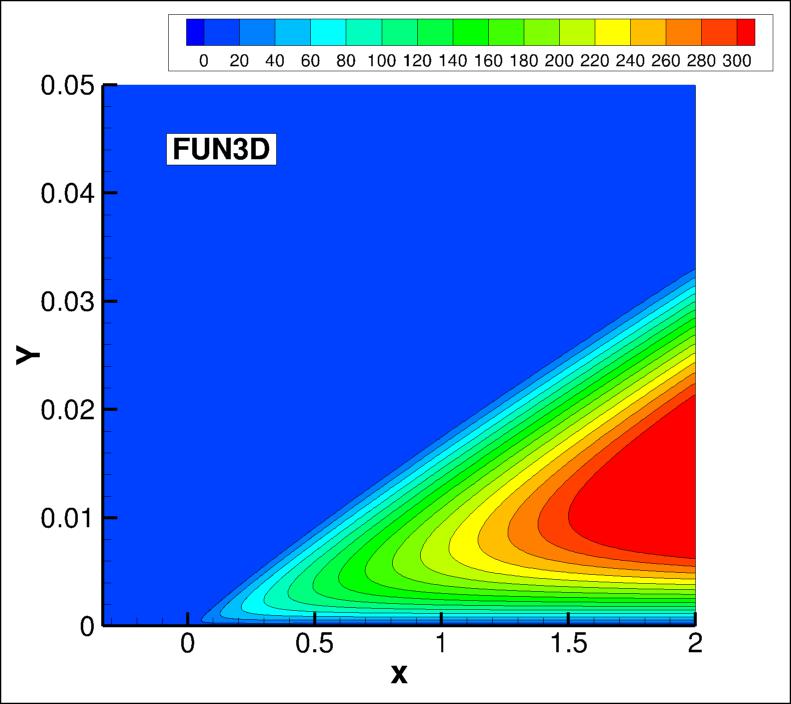

The eddy viscosity contours (nondimensionalized by freestream laminar viscosity) from SA-QCR2000

from the two codes on the finest 545 x 385 grid are shown

in the following plots (y-scale expanded for clarity). They are essentially indistinguishable.

(Note legends do not necessarily reflect min and max values.)

The data files that generated the above plots are given here:

mut_contours_saqcr_cfl3d.dat.gz (1.3 MB) (CFL3D) and

mut_contours_saqcr_fun3d.dat.gz (3.0 MB) (FUN3D).

that these are both gzipped

Tecplot

formatted files, so you must either have Tecplot or know how to read their format in order to use these

files.

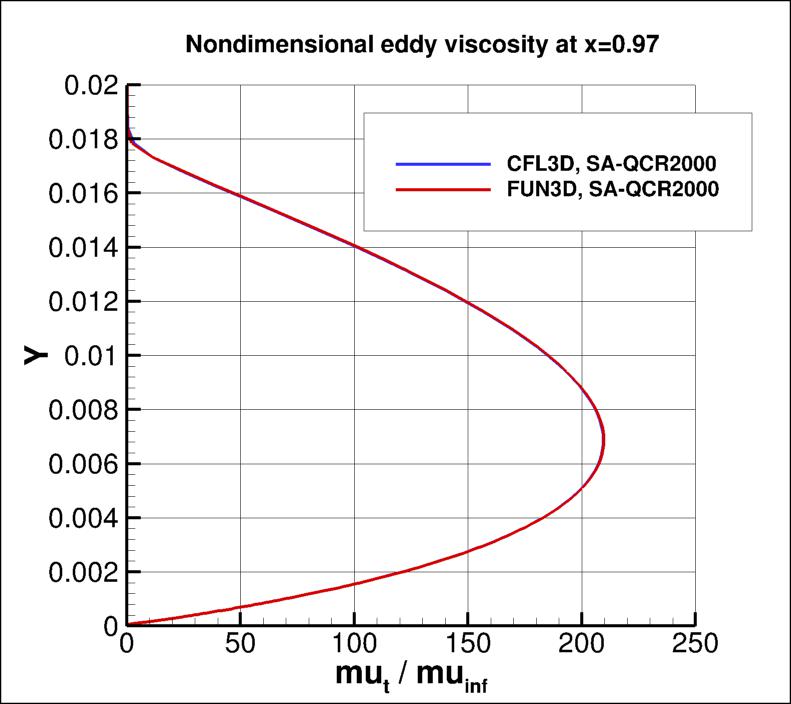

Using the finest 545 x 385 grid, a detail of the extracted nondimensional eddy viscosity profile at

x=0.97 is shown below. They are essentially the same for both codes.

The data file that generated the eddy viscosity profile at x=0.97 is given here:

mut_97_saqcr.dat.

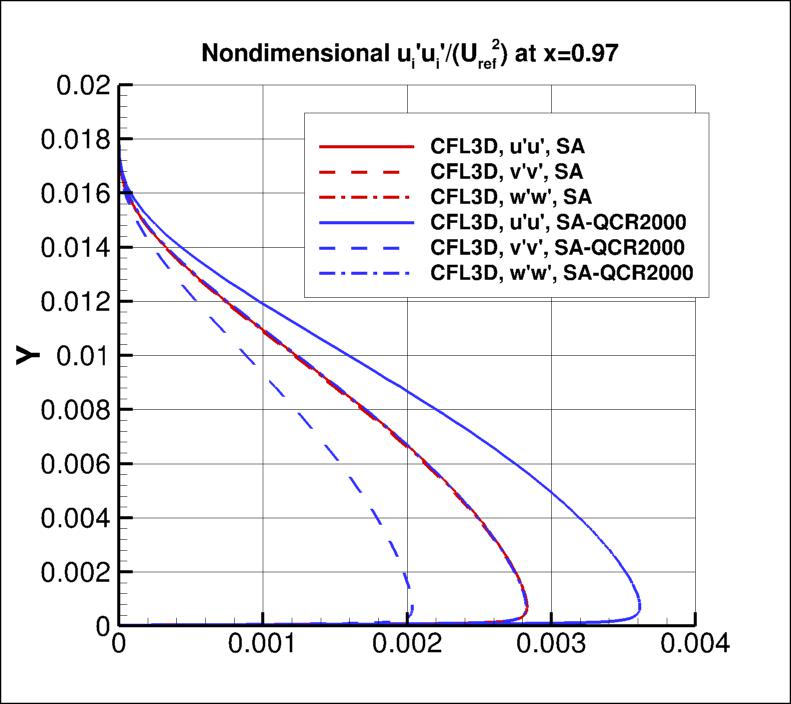

The main advantage to employing the quadratic constitutive relation (QCR) in SA-QCR2000 is that it better represents

the turbulent normal stress differences in boundary layers. These may be important in some situations (for example,

when computing flow near corners). Below, results for

are plotted for both SA and SA-QCR2000

on the finest grid (CFL3D only) in order to show the difference. Note that the normal stresses include a 2/3*rho*k term (see

Notes on Running the Cases with CFD, note 3).

However, for SA-based models, k does not "exist." It is therefore typically not included when evaluating the

turbulent stresses

while solving the Navier-Stokes equations. On the other hand, when outputting the normal

stresses for visualization, inclusion of an approximated k

term is sometimes done in order to produce more realistic absolute levels;

in this case here the k in the SA and SA-QCR2000 models is approximated (see AIAA-92-0439) for output only by:

k = mu_t/rho*sqrt(2*Sij*Sij)/(2*a1), where a1 is taken to be 0.155.

Note that the version

QCR2013 accounts approximately for the k term in a similar way, but in that model

the approximated k term is added while solving the Navier-Stokes equations

(this addition has no effect on the flowfield in incompressible flows, because it is

offset by a change in the pressure field.)

It can be seen from the plot that standard SA yields essentially no

difference between the three normal stresses, whereas the use of QCR2000 produces significantly larger u'u' and smaller v'v' levels.

Note that, as shown, the v component is "up" and the w component is spanwise.

The data file that generated the above plot is given in

uiprime_uiprime_cfl3d.dat.

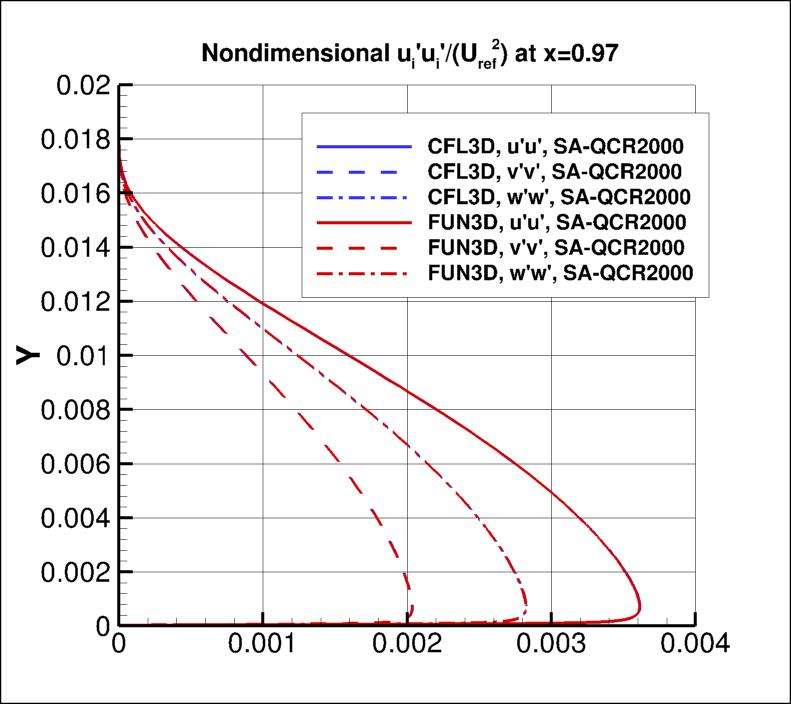

Results for the normal stresses from CFL3D and FUN3D are nearly identical, as shown below.

The data file that generated the above plot is given in

uiprime_uiprime_C+F.dat.

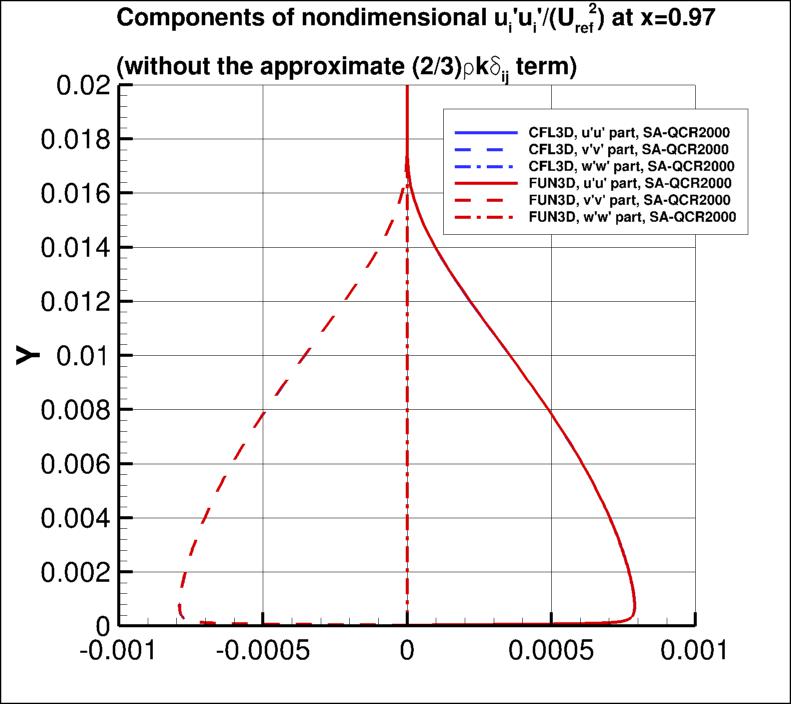

The normal stress results can also be plotted WITHOUT the 2/3*rho*k component included, as below (it is the normal stress differences

that really matter):

The data file that generated the above plot is given in

uiprime_uiprime_nok_C+F.dat.

Return to: 2D Zero Pressure Gradient Flat Plate Verification Case Intro Page

Return to: Turbulence Modeling Resource Home Page

Privacy Act Statement

Accessibility Statement

Responsible NASA Official:

Ethan Vogel

Page Curator:

Clark Pederson

Last Updated: 08/28/2018

.

For the interested reader, typical input files for this problem are given here:

.

For the interested reader, typical input files for this problem are given here: