|

Langley Research Center

Turbulence Modeling Resource

|

Exp: Smooth Body Separation

Experiment (SBSE) - Boeing Gaussian Bump with Error Function Shoulders

(also known as Boeing Speed Bump)

Return to: Data from Experiments - Intro Page

Return to: Turbulence Modeling Resource Home Page

The data on this page were provided by

Joseph Straccia and

Patrick Gray.

High-Level Table of Contents:

- Test Program Summary

- Wind Tunnel Description and Layout

- Geometry Definition

- Bump Model Parametric Representation

- CAD Definitions

- CMM Data

- Steps and Surface Roughness

- Experimental Conditions

- Experimental Data

- Notes on Data Format

- Guide to Importing the Data

- Empty Test Section Data

- Splitter Plate Only Data (No Bump)

- Bump Installed Data

- List of Related CFD Papers

1. Test Program Summary

A geometry named the Boeing Bump was conceived in 2015 with the goal of producing a highly separated flow

region downstream of the bump apex while minimizing the tunnel sidewall boundary layer interactions

that have previously been the cause of coupling between the flow separation and the corner flow physics.

The three-dimensional wall mounted bump model initially accelerates the flow due to a favorable pressure

gradient (FPG) and then quickly decelerates the flow in an adverse pressure gradient (APG) region to

induce a strong separated flow region. A three-year test campaign conducted at the University of Notre

Dame between 2020 and 2023 sought to explore the flow characteristics that give rise to the highly

turbulent, three-dimensional separation downstream of the bump apex. The goals, methods and results

of the Smooth Body Separation Experiment (SBSE) are documented in detail in the test reports available here:

Additional documentation can be found in the following publications:

Gray, P. D., Lakebrink, M., Straccia, J., Thomas, F.,

Corke, T., Gluzman, I., "Experimental and Computational Evaluation of Smooth-Body Separated Flow over Boeing Bump,"

AIAA Paper 2023-3981, Jun 2023,

https://doi.org/10.2514/6.2023-3981.

Gluzman, I., Gray, P., Mejia, K., Corke, T. C.,

and Thomas, F. O.,

"A Simplified Photogrammetry Procedure in Oil-film Interferometry for Accurate Skin Friction Measurement over Arbitrary Geometries,"

Experiments in Fluids, Vol. 63, Article No. 118, 2022,

https://doi.org/10.1007/s00348-022-03466-x.

Gray, P., Gluzman, I., Thomas, F., Corke, T.,

Mejia, K.,

"Characterization of Separated Flow over the Boeing Bump,"

AIAA Paper 2022-3342, June-July 2022,

https://doi.org/10.2514/6.2022-3342.

Gray, P., Gluzman, I., Thomas, F., Corke, T.,

Mejia, K.,

"Experimental Characterization of Smooth Body Flow Separation

OverWall-Mounted Gaussian Bump,"

AIAA Paper 2022-1209, January 2022,

https://doi.org/10.2514/6.2022-1209.

Gray, P., Gluzman, I., Thomas, F., Corke, T.,

Lakebrink, M. T., Mejia, K.,

"A New Validation Experiment for Smooth-Body Separation,"

AIAA Paper 2021-2810, August 2021,

https://doi.org/10.2514/6.2021-2810.

A zip file containing all geometry definition

and data files from the experiment can be downloaded here. The download size is 3.1 GB.

Alternatively,

smaller zip files containing specific data types are linked in the following subsections of the web page.

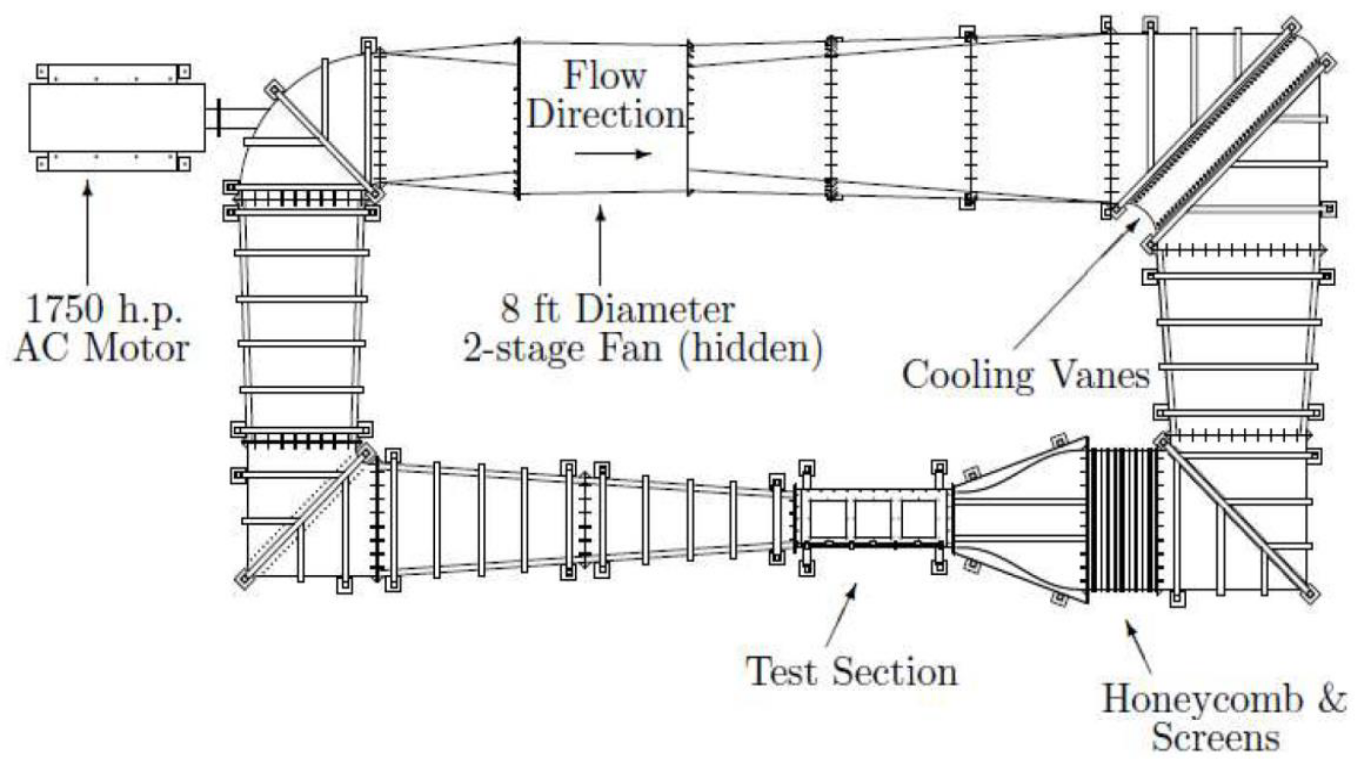

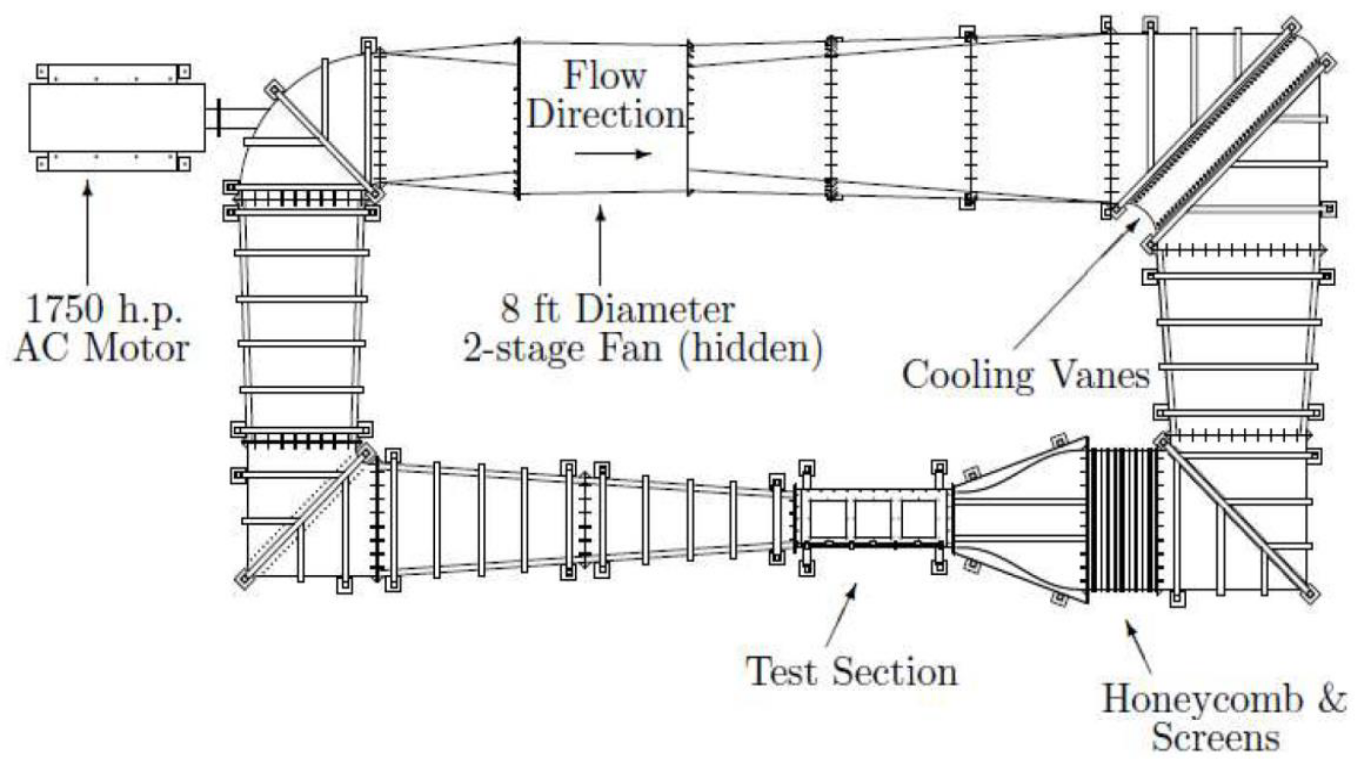

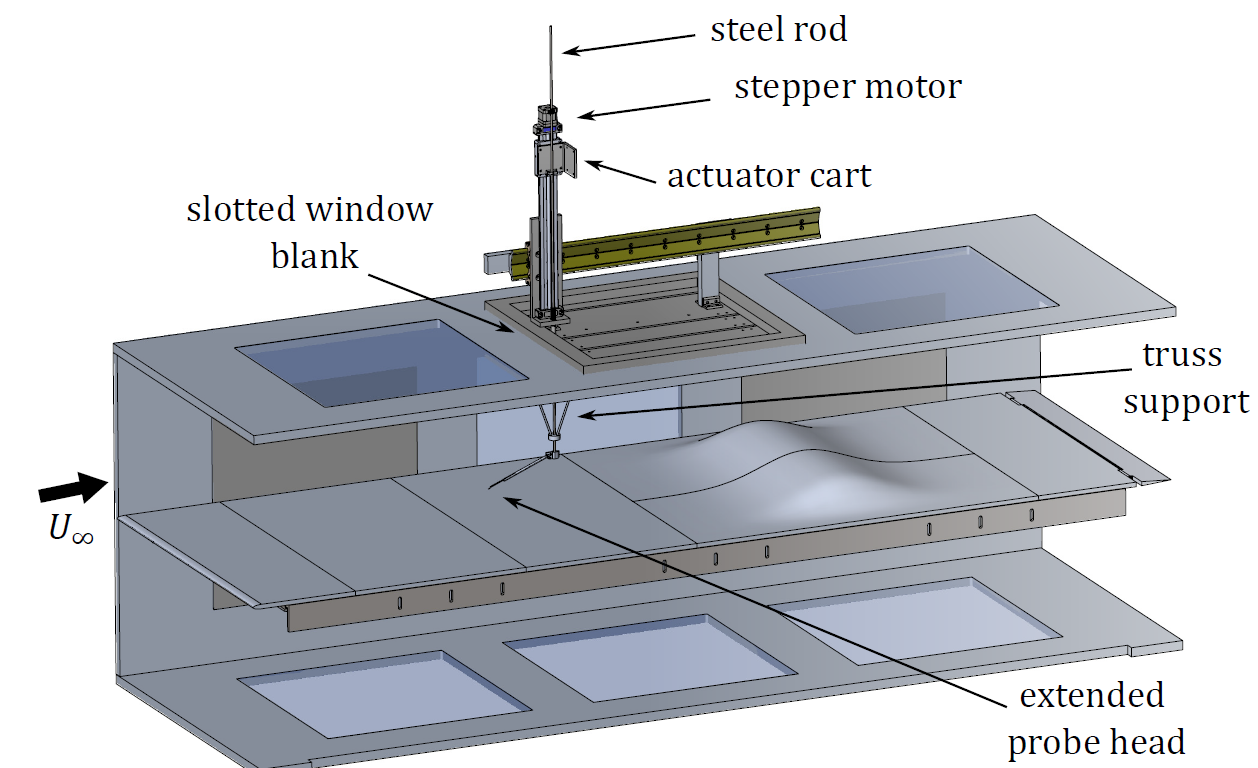

2. Wind Tunnel Description and Layout

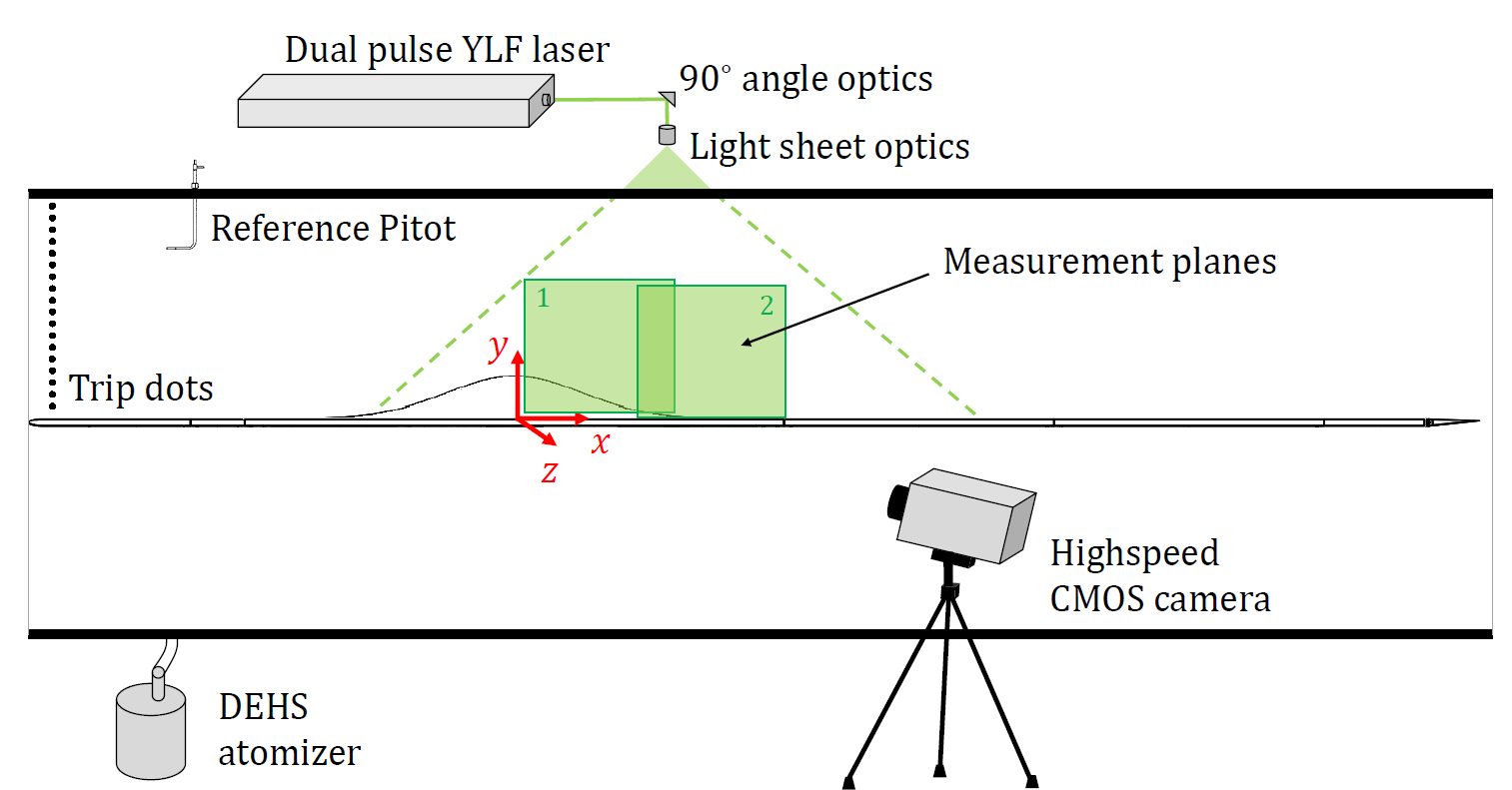

The experiments were conducted in the University of Notre Dame's Mach 0.6 closed-loop wind tunnel.

The tunnel has a test section with a 0.91 x 0.91 m square cross section that extends 2.73 m in the

flow direction. Turbulence management consists of a honeycomb section followed by five seamless,

low-solidity screens, resulting in a turbulence intensity level of approximately 0.05% throughout

the tunnel Mach number range. The tunnel's turning vanes act as heat exchangers through which

water from a 125 ton chiller coupled with a 1000 ton-hr ice-storage system is pumped. This

allows the tunnel temperature to equilibrate to within 1 degree C for experimental runs up

to M = 0.5. The test facility is discussed in

Section 2.1 of the test report.

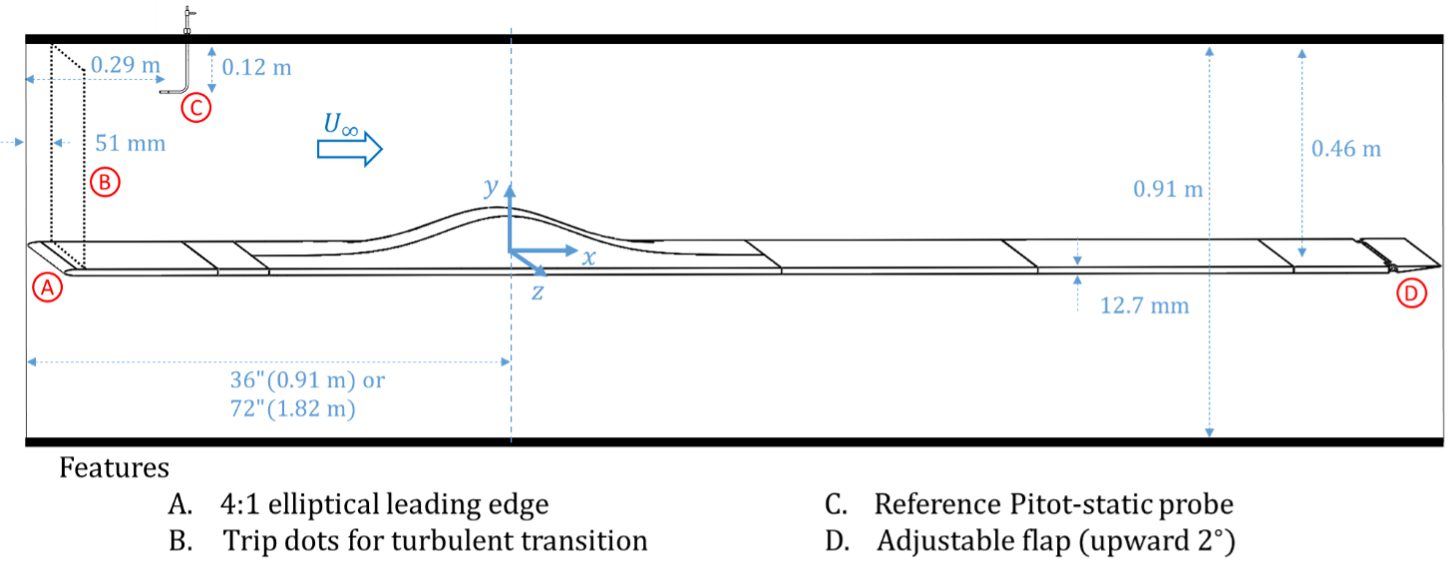

The bump model was installed into a 2.64m long splitter plate with a 4:1 elliptical leading edge and an

adjustable trailing edge flap, although the flap angle was fixed throughout the experiments.

Customized CADCUT cylindrical trip dots (flat top with sharp edges) that were 0.292 mm tall, 1.27 mm

in diameter and spaced 2.5 mm between centers were placed 51 mm downstream of the elliptical leading

edge (and the upstream edge of the removable test section) on the splitter plate surface and along the

interior sidewalls and ceiling of the wind tunnel test section. The trip dots were present for the

splitter plate and bump installed testing but not for the empty test section qualification

measurements. See

Section 2.2

in the test report for more details on the splitter plate and trip dots.

3. Geometry Definition

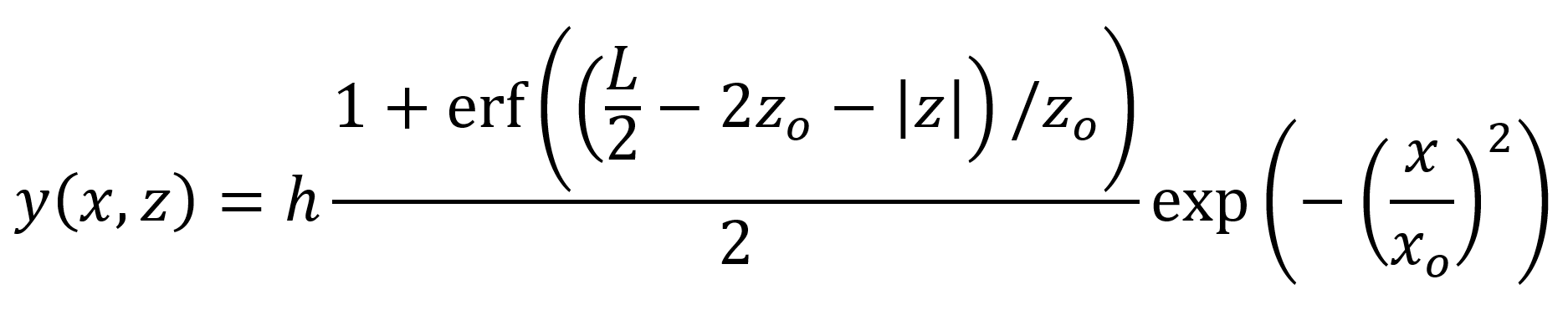

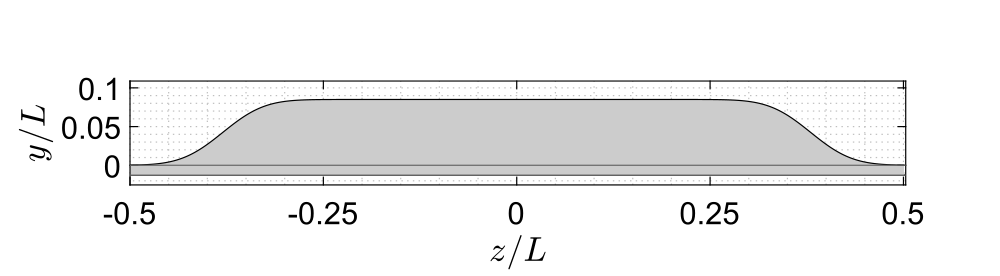

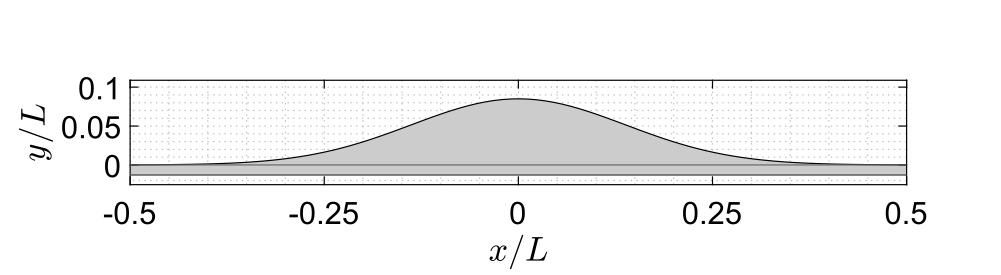

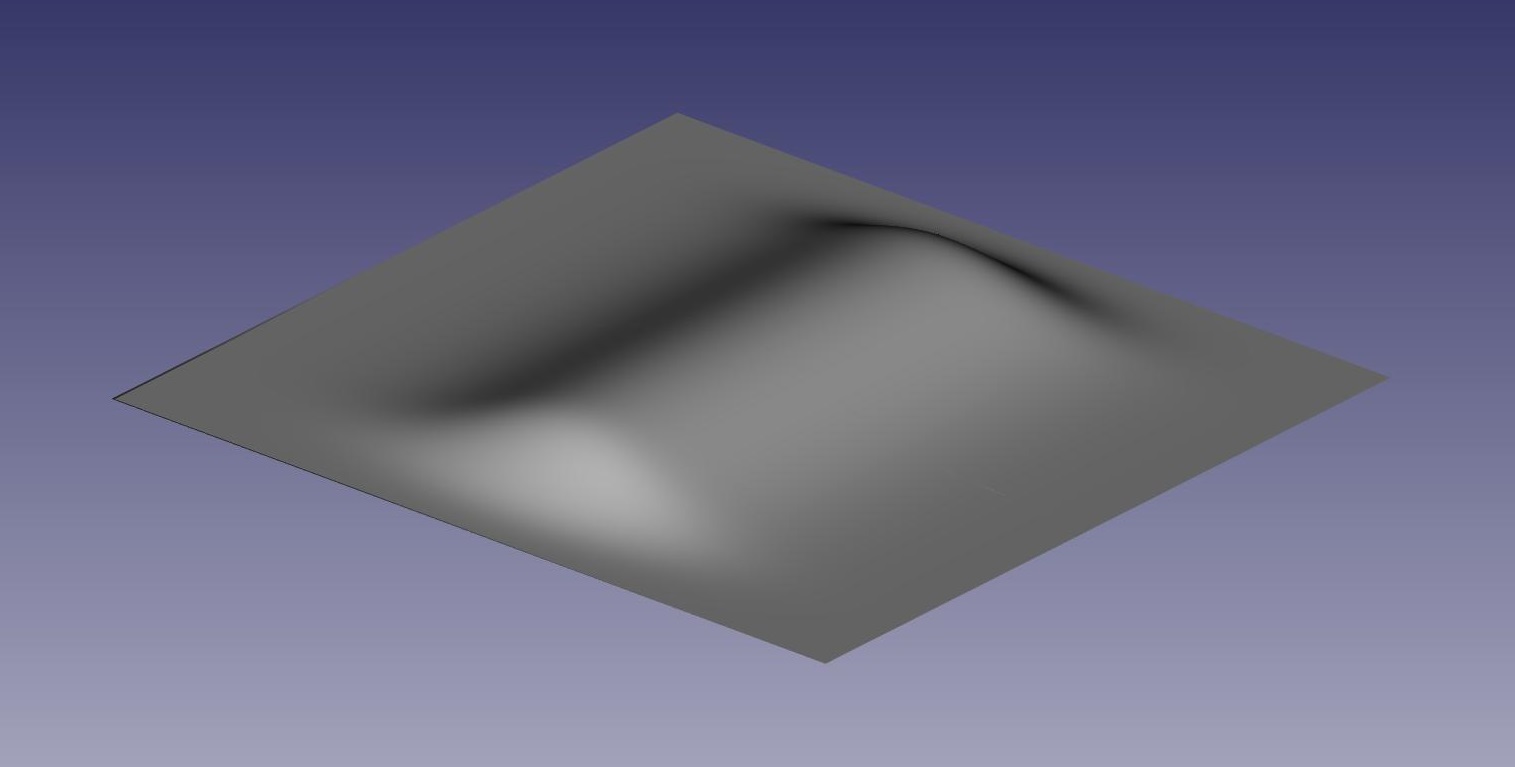

3.1. Bump Model Parametric Representation

The Boeing Bump geometry consists of a surface whose height is a Gaussian function in the streamwise direction,

x, and is tapered in the spanwise direction, z, by an error function to give the bump its "shoulders."

For the geometric parameters, the model uses L = 36 inches = 0.9144 m (the width of the tunnel), x0/L = 0.195,

z0/L = 0.06, and h/L = 0.085.

Section 2.2

in the test report describes the bump model.

3.2. CAD Definitions

3.2.1. Bump Geometry

The following files provide the definition for the bump alone at the test scale (L=0.9144m).

The two files represent the test model which was fabricated with one half wider that the other

so that the joining seam was off centerline. Therefore, the left-hand side and right-hand side

definitions are not exact halves of the configuration. Files are in IGS format.

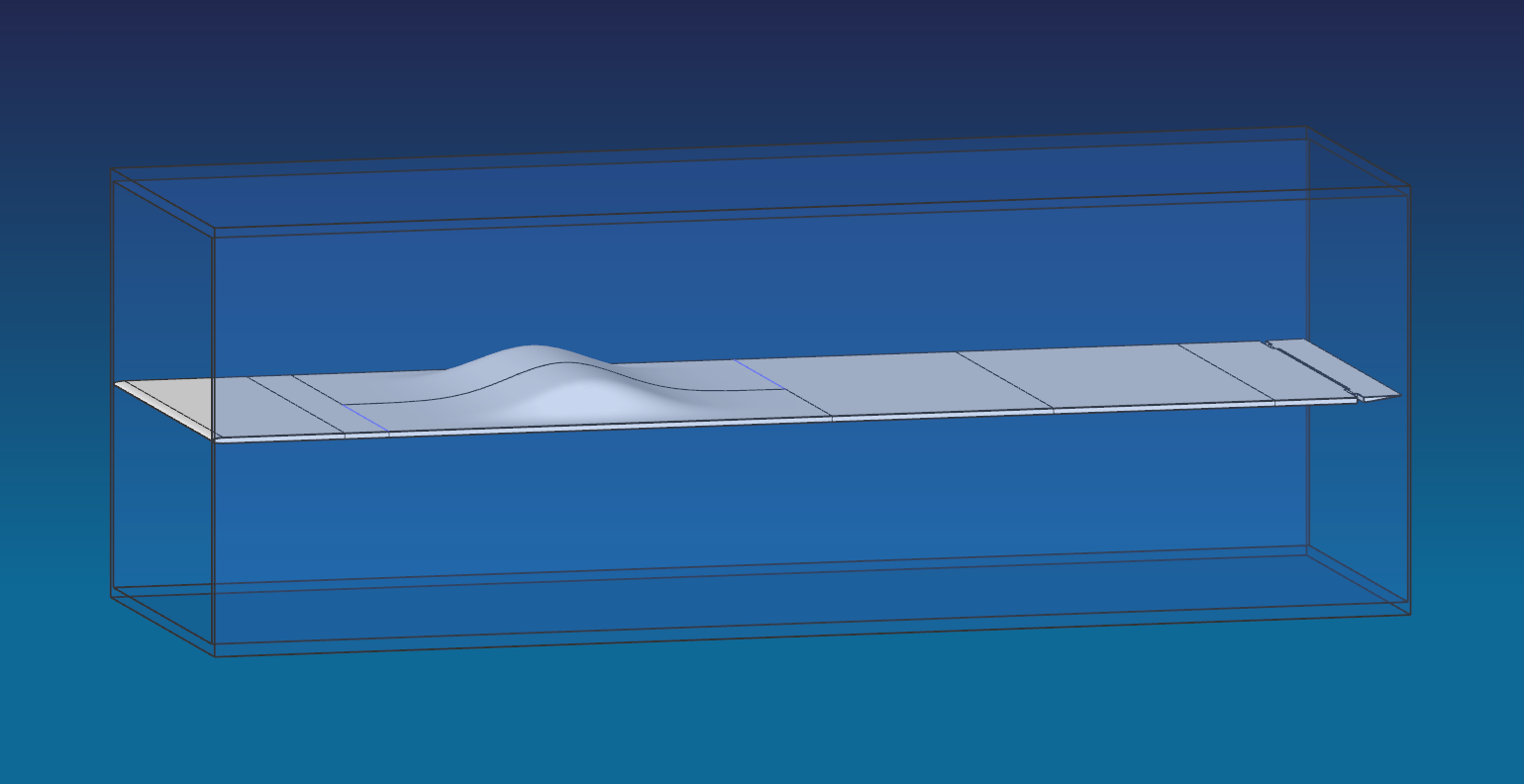

3.2.2. Wind Tunnel Test Section, Splitter Plate and Bump Model

The following assembly includes the test section walls, the splitter plate with the leading edge

ogive and trailing edge flap, the wall seals and the bump installed with its apex 0.9144m

(Xapex/L=1) downstream from the splitter plate leading edge (i.e., Configuration A). Note that the

orientation of this CAD assembly is different than the bump alone files. Like with the CAD of the

bump alone, the bump CAD definition comes in two pieces, with the joining seam offset from the tunnel

centerline. Files are in IGS, X_T, STEP and SLDASM formats.

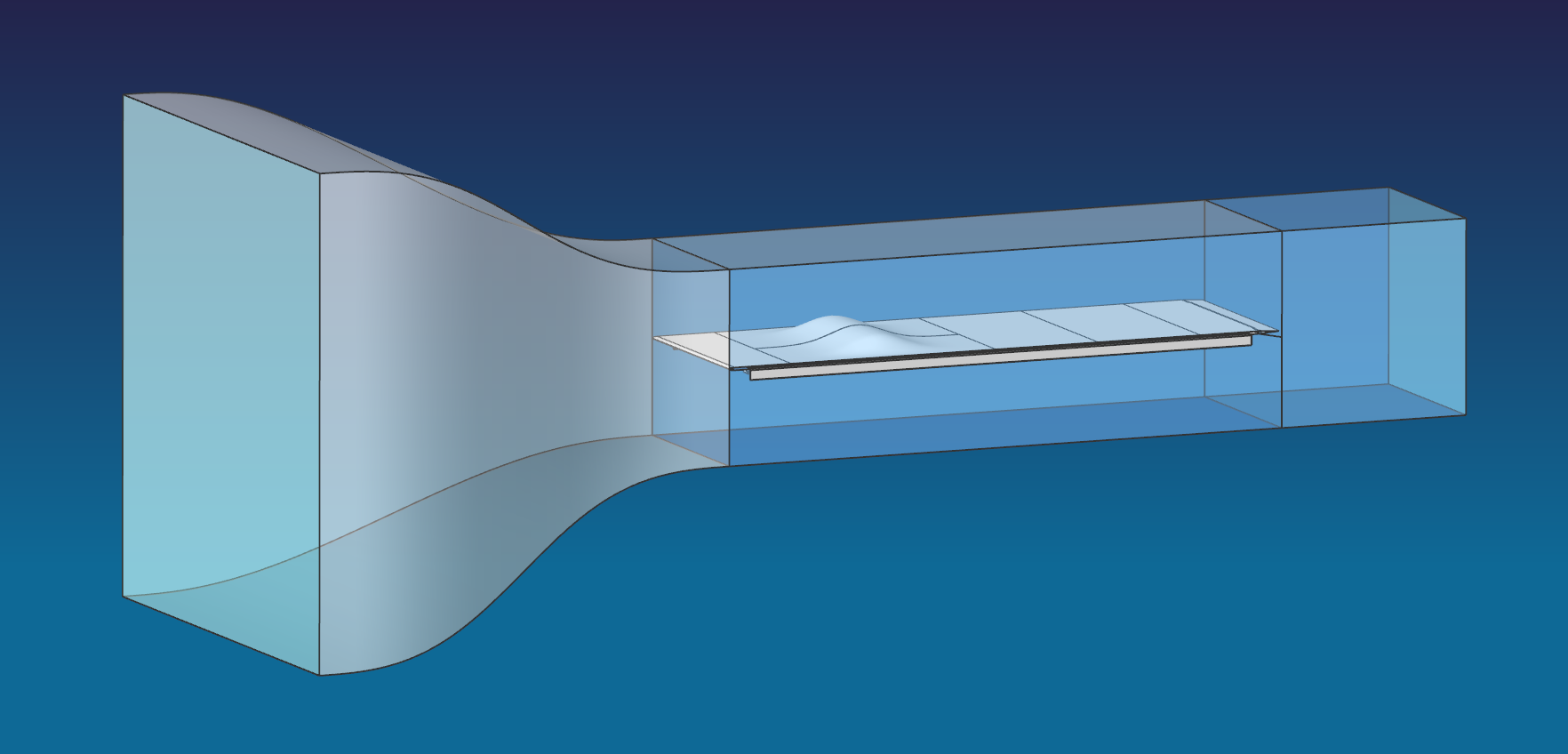

3.2.3. Wind Tunnel Contraction and Downstream Extension

The following assemblies include the wind tunnel contraction, the test section walls and a downstream extension.

In the test section the splitter plate with the leading-edge ogive and trailing edge flap is installed including

the definition for the mounting L-brackets and plate mounting fixtures. In one assembly the bump model apex

is located 0.9144 m (Xapex/L=1) downstream from the splitter plate leading edge (Configuration A) and in the

other the bump apex is located 1.8288 m (Xapex/L=2) downstream from the leading edge (Configuration B).

Files are provided in IGS format.

3.3 CMM Data

The as-manufactured geometry was verified with a coordinate measuring machine (CMM). The measured contours were

confirmed to be within +-0.125 mm of the CAD model for each of the plate sections.

Reports containing the CMM measurements can be downloaded here:

3.4 Steps and Surface Roughness

The test article including the splitter plate and bump sections were fabricated with a surface roughness

RMS approx 305 micrometer. The steps between plates were measured to be < 0.063 mm.

A more detailed report of the panel step and surface finish measurements can be downloaded here:

4. Experimental Conditions

The wind tunnel experiments were conducted in air at ambient conditions. Although cooling via the turning

vanes was utilized during the experiments its purpose was to hold air temperature to within a 1 degree

C band within the wind tunnel. Details on the reference conditions within the test section during a

specific measurement are documented in the header section of the corresponding data file.

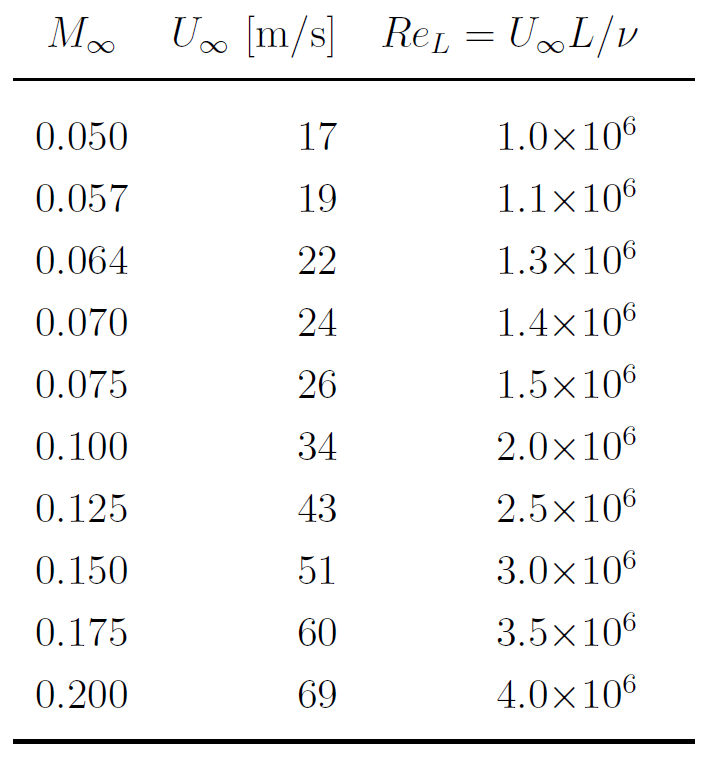

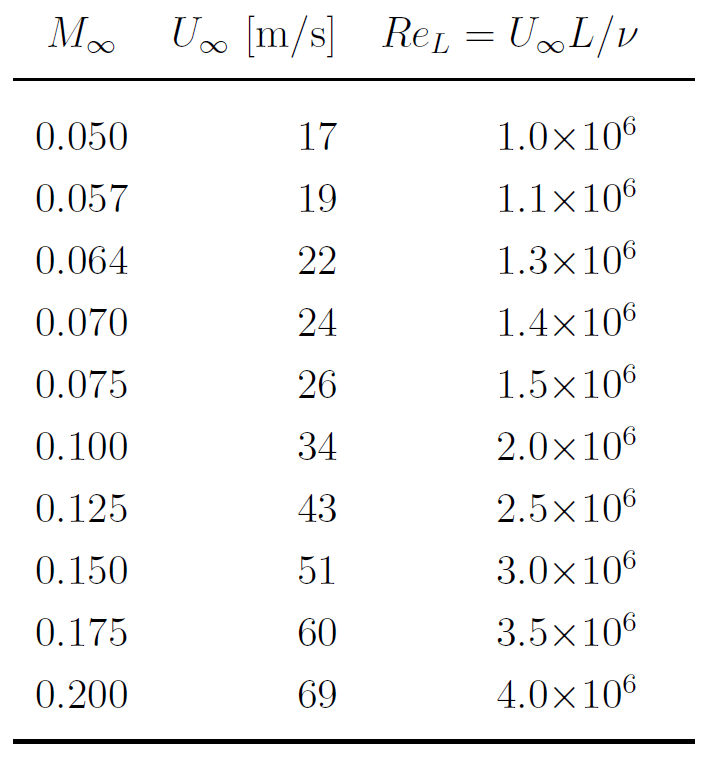

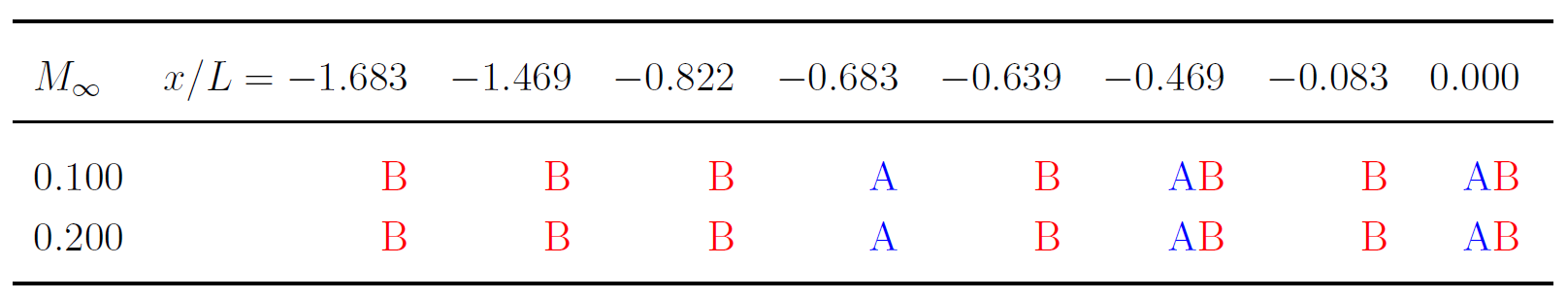

Two aerodynamic parameters were varied in the experiments to understand their influence on smooth

body separation. The first was the flow Mach number or Reynolds number which was varied by changing the

air speed via the fan RPM. For most measurements the emphasis was on M=0.1 and M=0.2, however, in several

cases data were obtained across a larger set of conditions. The following table lists all Mach numbers

tested along with the corresponding free steam velocity and Reynolds number (based on the test section width).

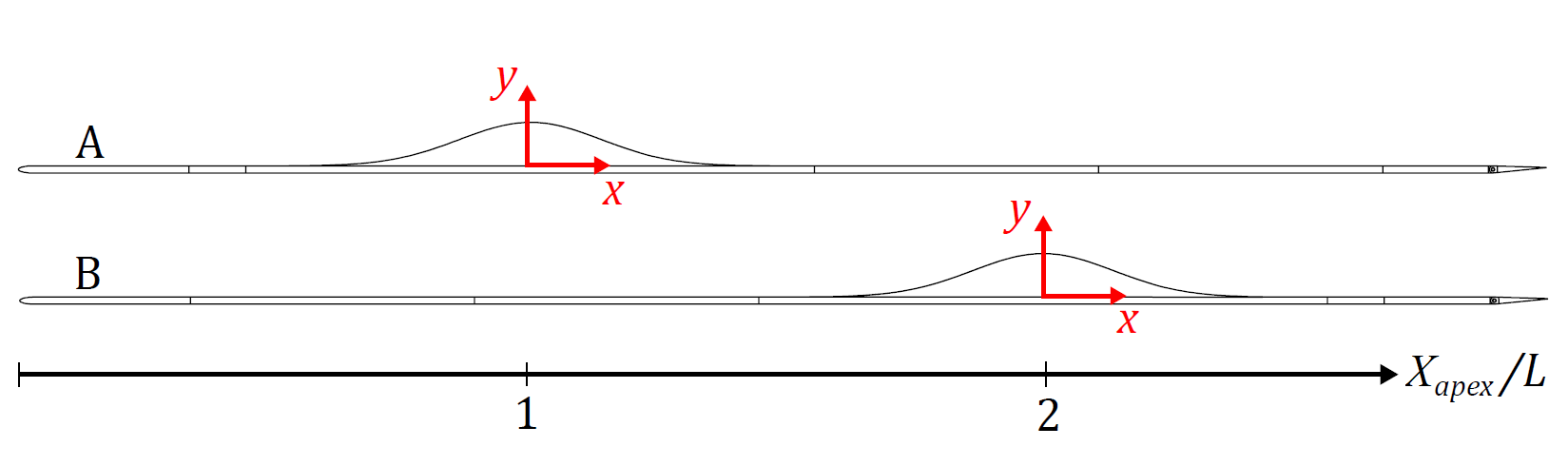

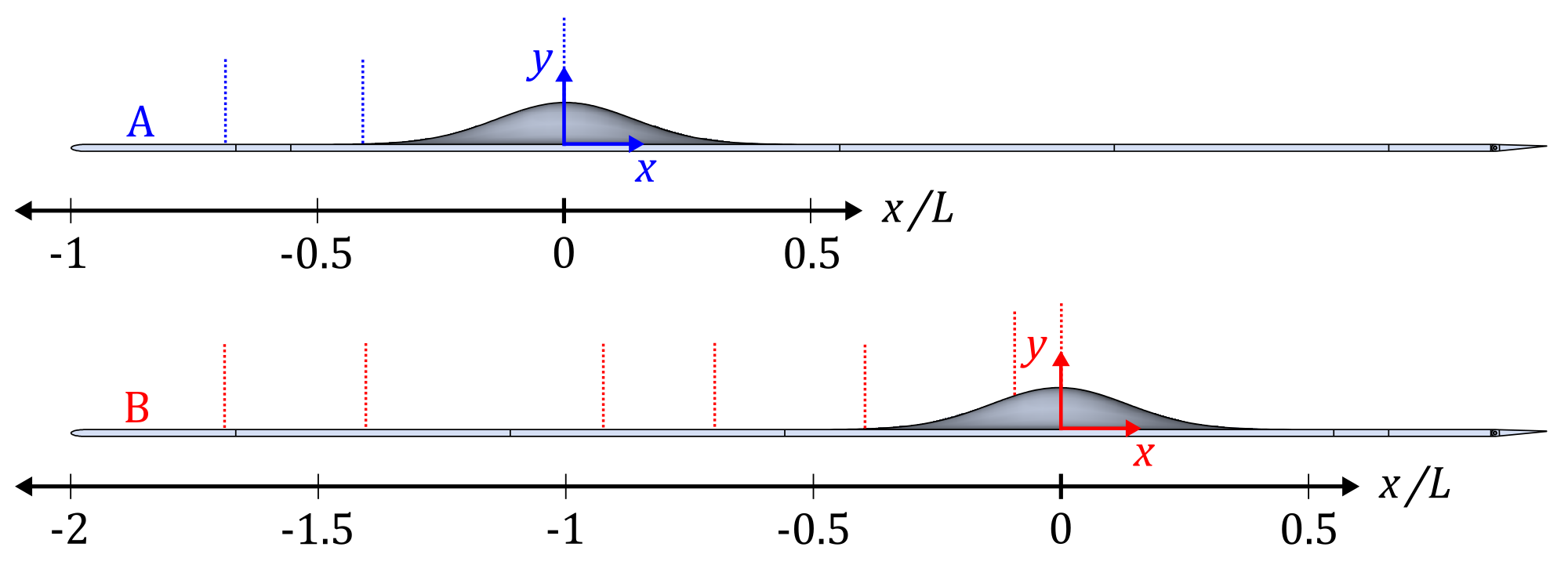

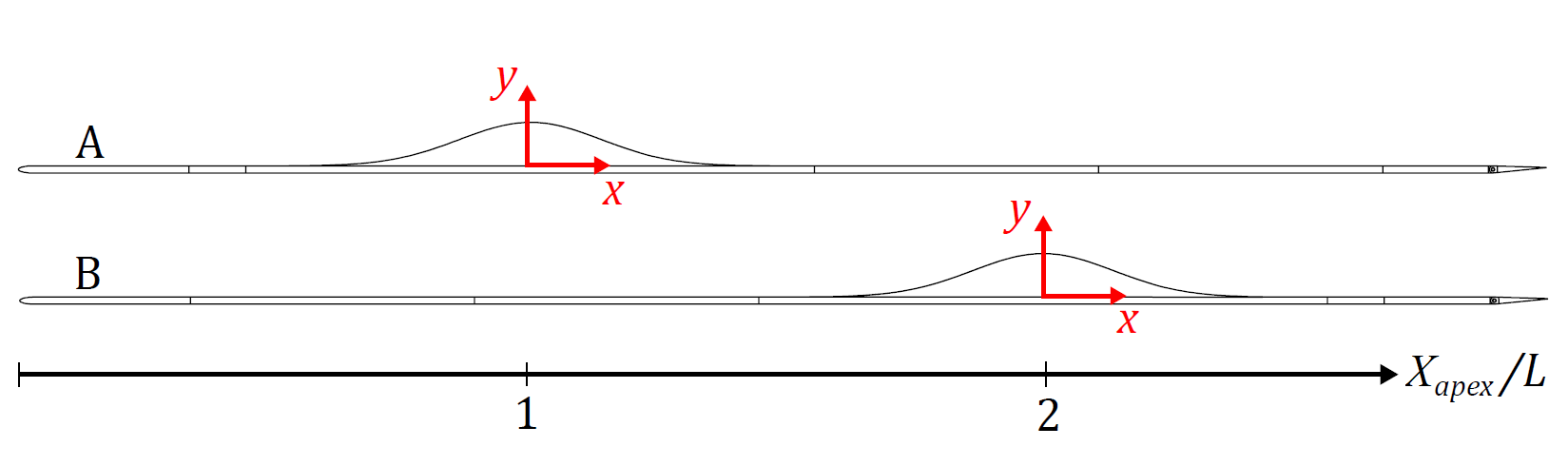

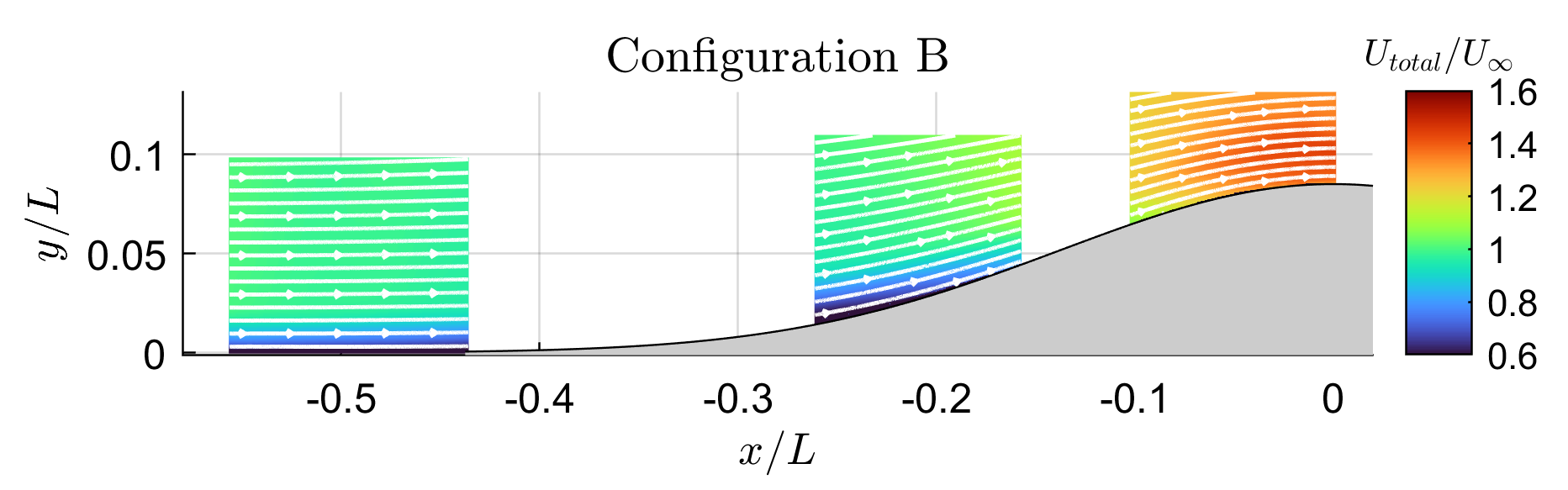

The second aerodynamic parameter varied was the boundary layer thickness upstream of the bump.

This was varied independently of freestream velocity by placing the bump at different locations on the

splitter plate so that the boundary layer had more or less distance to develop. Accordingly,

two bump configurations were tested in this experimental study: configuration A where the bump

apex was postitioned one test section width downstream from the splitter plate leading edge and

configuration B where the bump apex was two test section widths downstream from the leading edge.

An emphasis was placed on obtaining data with the bump in configuration A.

Section 2.3

of the test report provides information on the coordinate systems and notation for the bump configurations tested.

See Section 4.1

of the test report for details on the experimental test conditions.

5. Experimental Data

5.1. Notes on Data Format

All experimental data are provided in human-readable ASCII DAT file format (.dat). The beginning of these

files includes a commented block of text which specifies the bump geometry, test configuration, references

conditions, derived quantities and variable name descriptions, with units. The data table consists of a

single uncommented line with the parameter names followed by the data itself. These DAT files are readable

by Microsoft Excel, MATLAB, Python and Tecplot. Additionally, the PIV and Kulite data are also provided

in binary MATLAB MAT file format (.mat). The MAT files have smaller file sizes than the DAT files and

for the PIV data the MAT file format preserves the 2D array structure whereas the DAT files store the

2D data as 1D arrays which have to reshaped after import. The MAT files can be read by MATLAB and Python.

Two coordinate systems are utilized in the data files. First, a right-handed global coordinate system

with respect to the test section is denoted using capital X, Y, and Z to represent streamwise, vertical,

and spanwise distances from its origin, respectively. The origin of the global coordinate system is

located at the inlet of the test section, on the bottom wall, and at the center span between the left

and right side walls. Second, a right-handed bump-based coordinate system is implemented when distances

with respect to the bump are referenced, regardless of the global position of the bump apex. Here,

lower case symbols x, y, and z represent streamwise, vertical, and spanwise directions, respectively.

The origin of the bump-centric coordinate system is in the same streamwise plane as the bump apex, and

located vertically at the top surface of the flat plate, and at the center span of the tunnel between

the left and right side walls. For data files where the filename includes the position of the measurement

the global coordinate system (X,Y,Z) is used. Within the data files the data coordinates are provided

in both the global (X,Y,Z) and bump-centric (x,y,z) coordinate systems.

5.2. Guide to Importing the Data

5.2.1. Importing .dat files into MATLAB

Generally, the .dat files can be imported into MATLAB by simply entering data=readtable('filename.dat'); in

the command window. For some files MATLAB does not correctly handle the commented header section and

throws an error. Therefore, a more robust way to import the data is to use the following commands in an m-file.

infile = 'EmptyTunnel_TotalPressureBL_X486mmProfileB_M0p10.dat';

comment= '%';

S=readlines(infile);

ch = S{1};, line=1;

while ch(1) == comment

line = line + 1;

ch = S{line};

end

clear S

data=readtable(infile,'NumHeaderLines',line-1);

Data are then accessed from the structure using data.variablename, e.g., data.U.

PIV data which are obtained as a 2D array will import from DAT files as 1D vectors. The following is an example of how to

reshape and plot the SPIV data:

data = readtable('BumpConfigA_SPIVcrossplanes_X1143mm_M0p200.dat');

ydim = length(unique(data.y_L)); zdim = length(unique(data.z_L));

zL = reshape(data.z_L,ydim,zdim);

yL = reshape(data.y_L,ydim,zdim);

U = reshape(data.U,ydim,zdim);

figure

contourf(zL,yL,U,256,'EdgeColor','none')

c = colorbar;

title(c,'$U$ [m/s]','interpreter','latex');

axis equal

xlabel('$z/L$','interpreter','latex')

ylabel('$y/L$','interpreter','latex')

5.2.2. Importing .mat files into MATLAB

MAT files are imported into MATLAB by entering load('filename.mat') in the command window.

Data are then accessed from the structure using data.variablename, e.g., data.U.

5.2.3. Importing .dat files into Python

The following commands will import the data in the .dat file and preserve parameter names while ignoring commented lines in the header.

import numpy as np

from io import StringIO

infile = 'EmptyTunnel_TotalPressureBL_X486mmProfileB_M0p10.dat'

input_data = open(infile,'r')

input_text = ''

comment = '%'

for line in input_data:

if not line[0] == comment:

input_text += line

data = np.genfromtxt(StringIO(input_text),delimiter='\t',names=True)

Data are then accessed from the structure using data['VariableName'], e.g. data['U'].

5.2.4. Importing .mat files into Python

import scipy.io

mat = scipy.io.loadmat('filename.mat')

5.2.5. Importing .dat files into Tecplot

Open the .dat file in a text editor and note the line number with the variable names and the line number of the first row of the data table.

Within Tecplot click File > Load Data... and navigate to the .dat file. Under Files of type

select All Files (*) if not already in that mode and click on the .dat file and then Open.

Under loader type select General Text Loader and then OK. Click Variables button and in the variables

window select Scan for Variable Names radio button and enter the line number of the variables in both the

Start Line and End Line boxes then press OK (the delimiter can be left as Auto).

Next click the Data button and in the data window enter the line number of the first row of the data table under

Start Line and select End of File radio button for the end line then click OK

(delimited can be left as Auto). Under Data Preview select the View Processed Data

radio button and then click Scan File. The data table should appear in the display window. Click OK.

The data should now be available for plotting in Tecplot under the Mapping Style dialog.

5.2.6. Importing .dat files into Microsoft Excel

Within Excel click File > Open and navigate to the .dat file location. Change the file type drop down from

All Excel Files to All Files (*.*). Click on the desired .dat file and click Open.

Under Original data type select Delimited then click Next. Under Delimiters check only the

Tab box then click Next. Under Column data format leave the radio button on General then click Finish.

Alternatively, the .dat file can be opened in a text editor (e.g. notepad, notepad++, etc) and the contents selected and copied.

Next within Excel, right click in the cell A1 and select paste. Excel will automatically apply a

tab delimiter when pasting the .dat file contents.

5.3. Empty Test Section Data

Prior to installation of the test article, an investigation of the empty test section was conducted to

quantify incoming flow quality. See

Section 3.1

in the test report for more information on this test phase.

5.3.1. Pitot-Static Rakes: Freestream Velocity

A traversing Pitot-static probe was used to investigate the uniformity of the empty test section

flow prior to installation of the test model or fixtures. Measurements were made at M=0.2. See

Section 3.1.1

in the test report for more information on the data obtained.

A zip file containing the flow velocity data obtained with the pitot-static probe in the empty test section can be downloaded here:

5.3.2. X-Wire: Three-Component Freestream Velocity and Turbulence Intensity

A traversing X-wire probe was used to investigate the freestream angularity and turbulence intensities within the

empty test section prior to installation of the test model or fixtures. The measurements were made at

M=0.1 and 0.2. See

Section 3.1.2

in the test report for more information on the data obtained.

A zip file containing the flow velocity data obtained with the X-wire probe can be downloaded here:

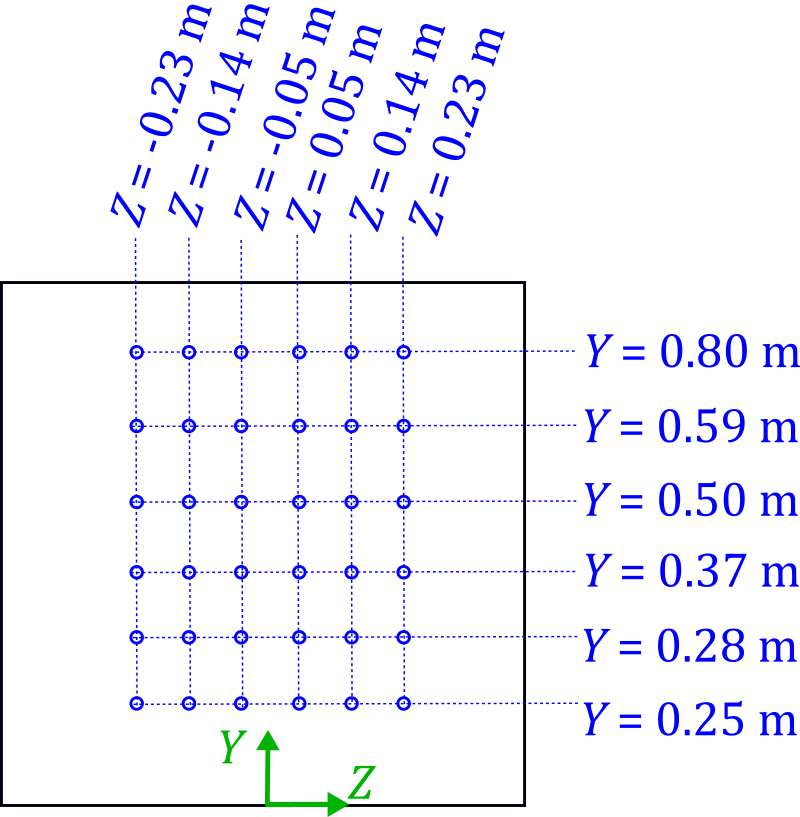

5.3.3. Total Pressure Probe: Test Section Wall Boundary Layer Measurements

A traversing total pressure boundary layer style probe was used to investigate the boundary layer development

on each of the four test section walls prior to the installation of the test model or fixtures. The

measurements were made at M=0.05, 0.1 and 0.2. See

Section 3.1.3

in the test report for more information on the data obtained. The

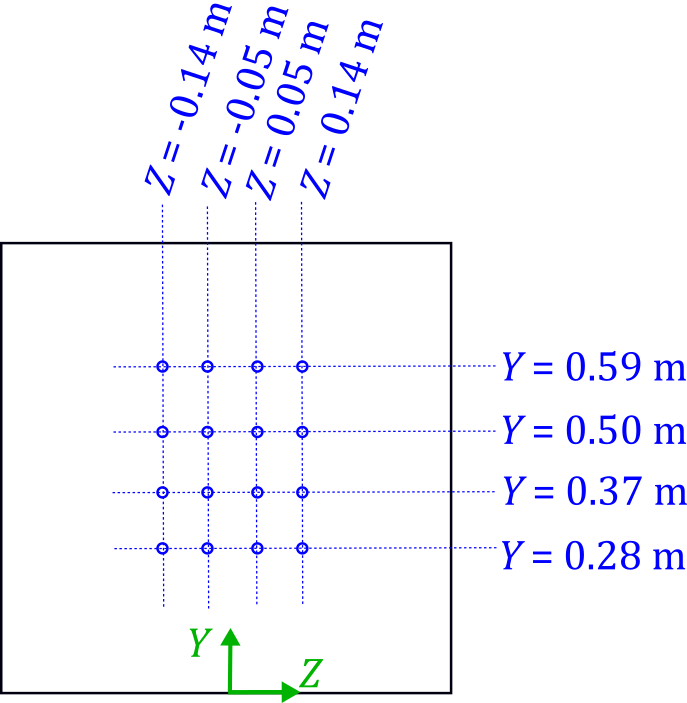

following figure visually depicts where the boundary layer profiles were measured within the empty test section.

A zip file containing the boundary layer profiles obtained on the empty test section walls using a total pressure probe can be downloaded here:

5.4. Splitter Plate Only Data (No Bump)

After the first test phase investigating the flow quality within the empty test section, the

splitter plate and associated fixtures were inserted into the test section. Without the bump installed, the

test bed consisted only of flat plate sections which allowed canonical boundary layer development with near

zero pressure gradient. See

Section 3.2

in the test report for more information on this test phase.

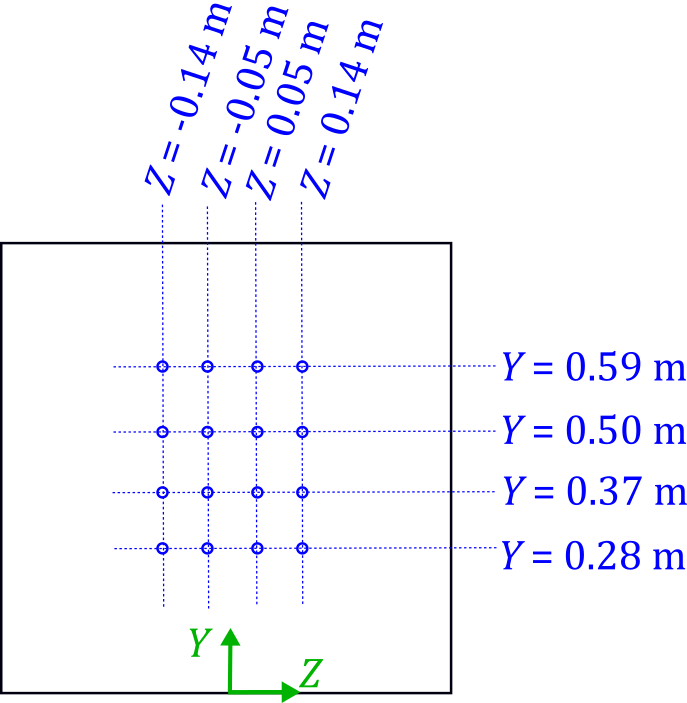

5.4.1. Hot-wire: Splitter Plate Boundary Layer Profiles

The hot-wire anemometry and traversing system described in

Section 2.4.3 in the

test report was used to obtain mean velocity profiles of the boundary layer on the splitter plate. The measurements were

made at M=0.1 and 0.2 for the splitter plate only configuration. See

Section 3.2.2

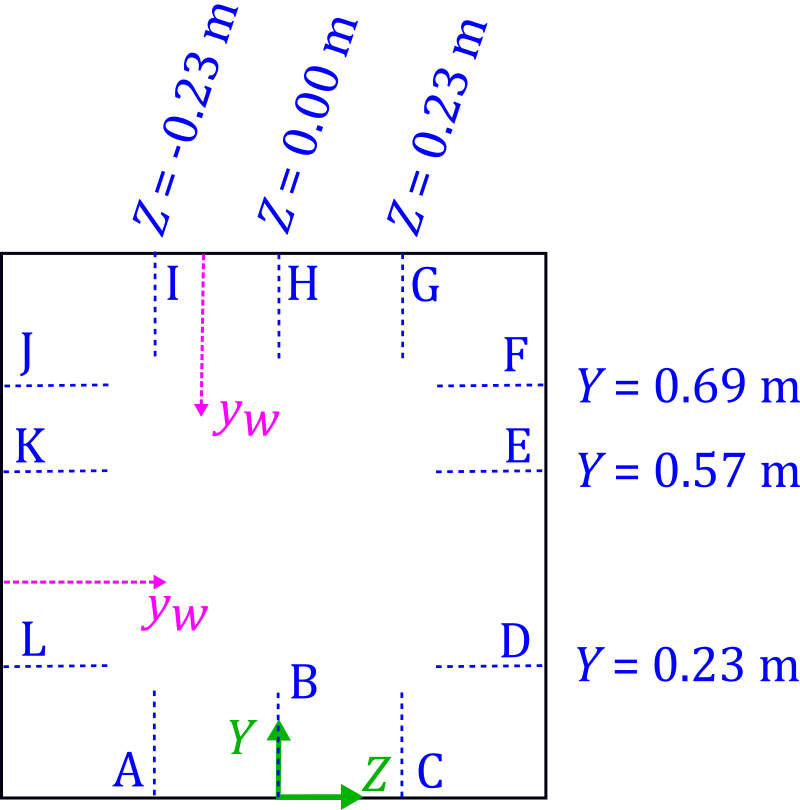

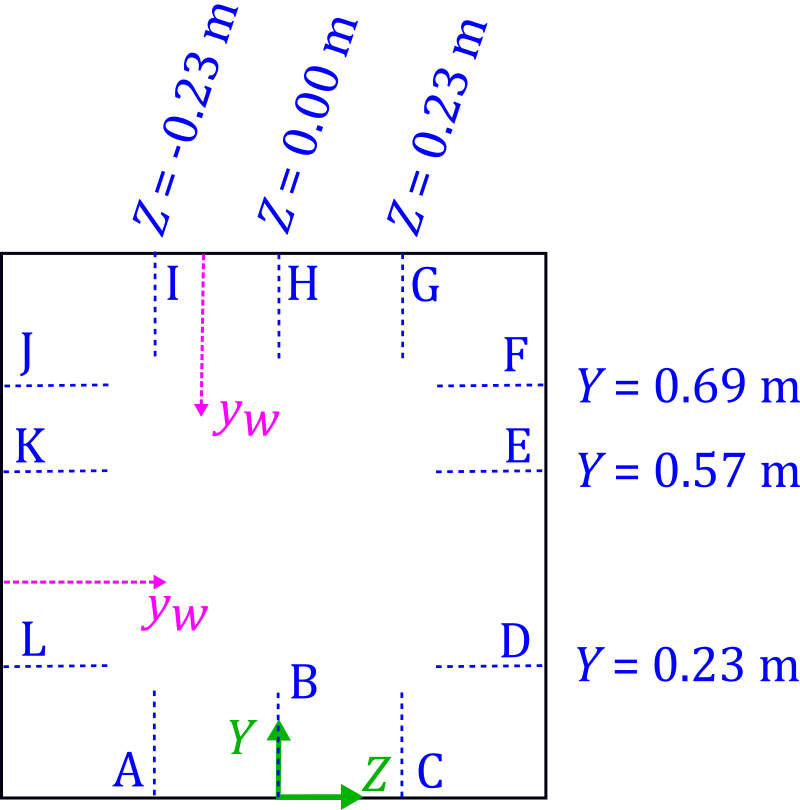

in the test report for more information on the data obtained. The following figure visually depicts

where the hot-wire data were obtained within the test section.

A zip file containing the boundary layer profiles obtained on the splitter plate using hot-wire anemometry can be downloaded here:

5.4.2. Oil Film Interferometry (OFI): Splitter Plate Skin Friction

The photogrammetric OFI technique described in

Section 2.4.4

in the test report was used to measure skin friction on the splitter plate prior to bump installation.

The measurements were made at M=0.2 for the splitter plate only configuration. See

Section 3.2.3

in the test report for more information on the data obtained. A zip file containing the skin friction

measurements obtained on the splitter plate using OFI can be downloaded here:

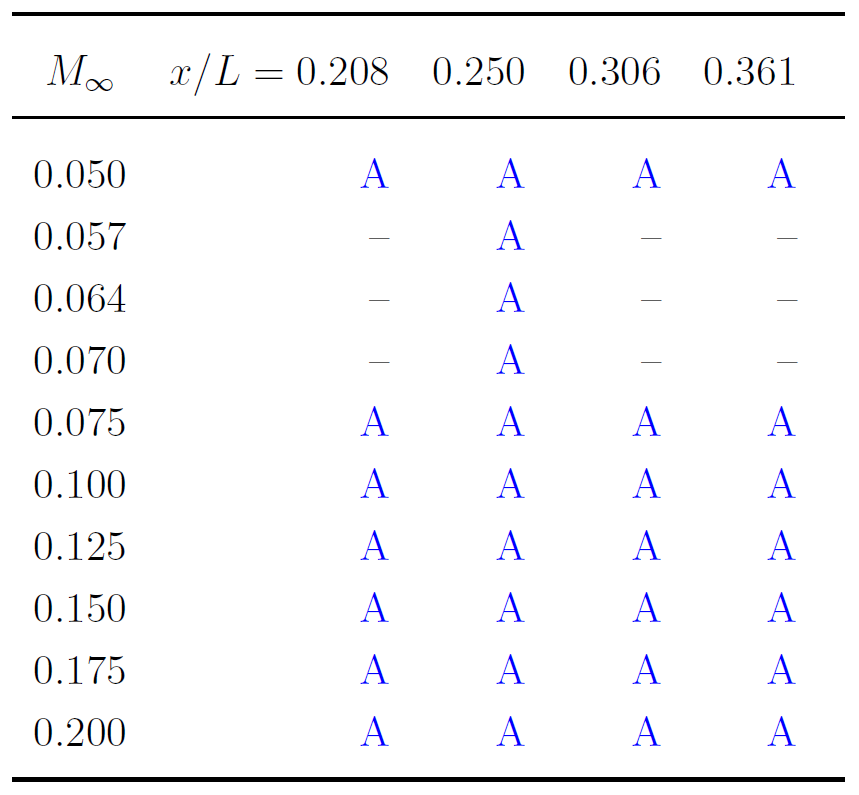

5.5. Bump Installed Data

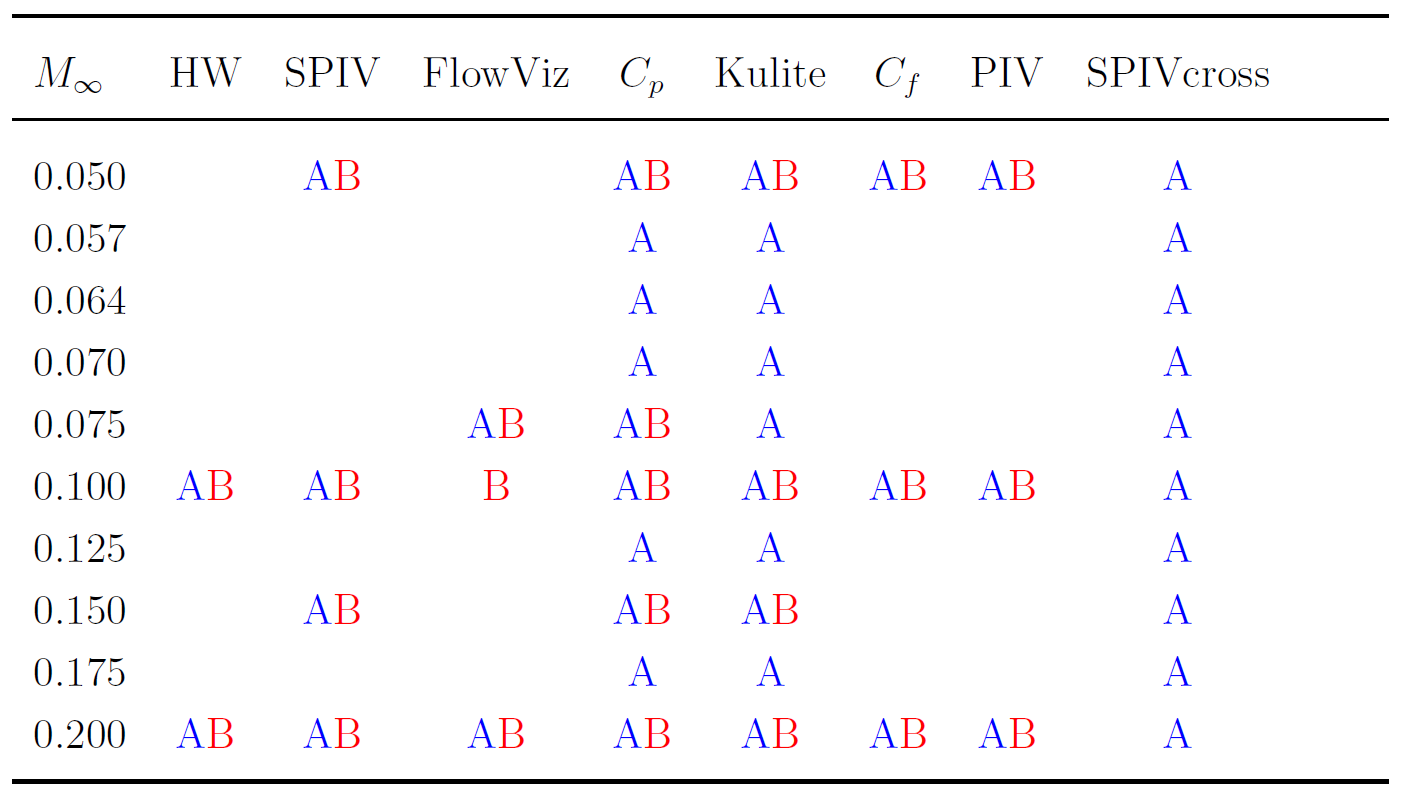

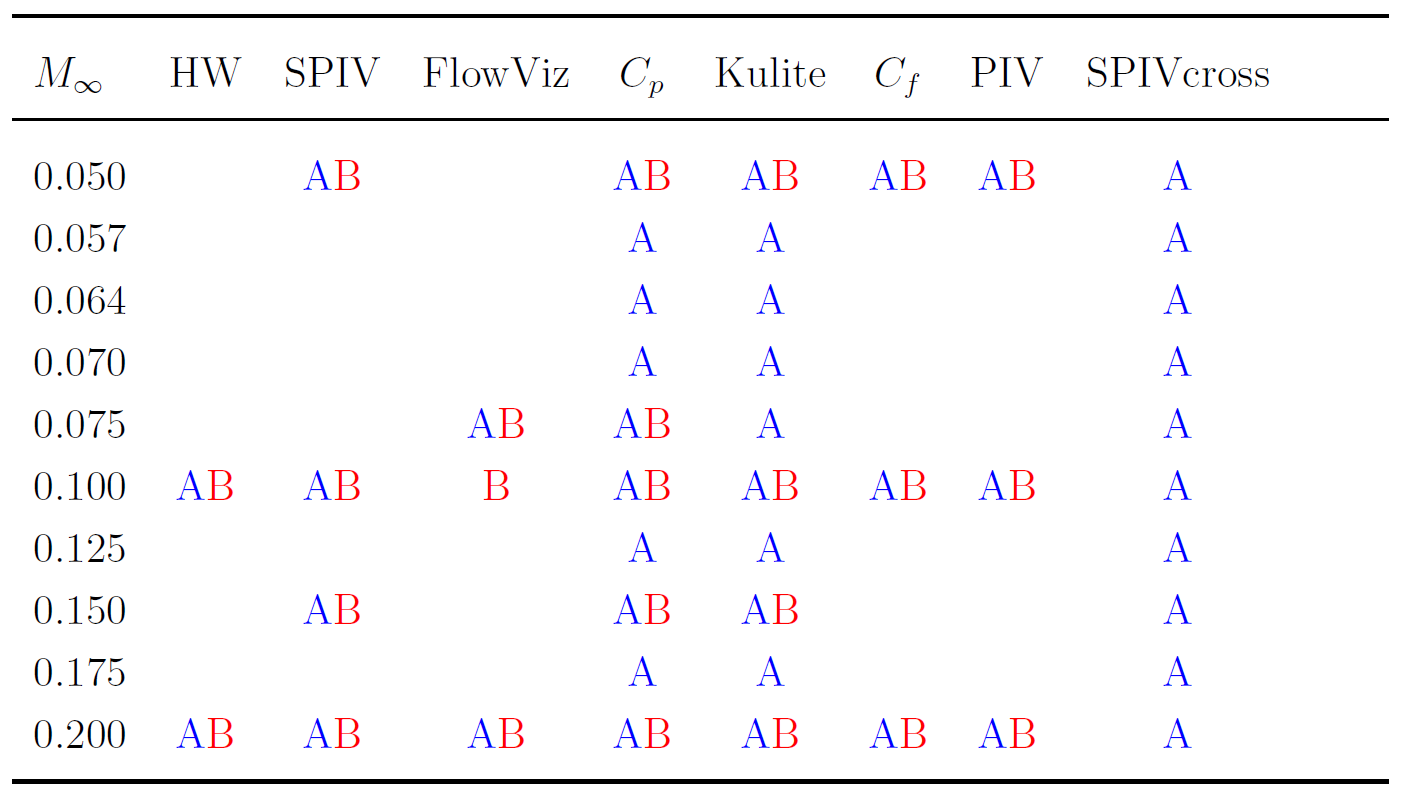

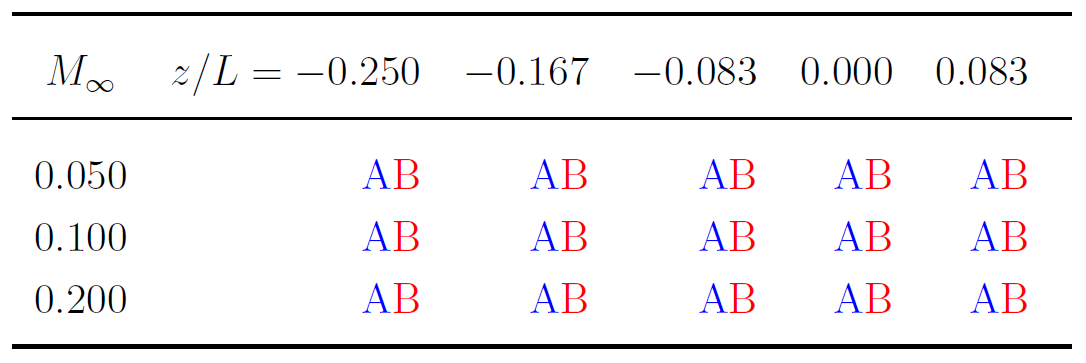

To achieve the core objective of this program, a series of flow diagnostics were conducted with the

speed bump model installed in the splitter plate. A high-level tabular summary of all experimental data

obtained with the bump model installed is provided in the following table which shows the flow speeds tested

using each of the diagnostic tools. The table also specifies the bump configuration tested at the reference

condition (A, B, or both). The quantities measured and corresponding experimental techniques employed

include: the boundary layer profiles using the hot-wire anemometry system (HW), the flow fields upstream

of the bump using SPIV (SPIV), the surface streamlines in the separated flow region using flow visualization

oil (FlowViz), the mean and instantaneous static pressure over the bump (Cp and Kulite, respectively),

the mean skin friction over the bump (Cf ), the separated flow field downstream of the bump using PIV (PIV),

and the separated flow field downstream of the bump in cross-planes using SPIV (SPIVcross). Additional data

summary tables are provided at the start of each of the following subsections which indicate the specific

locations where data were obtained within the flow field for the measurement type being discussed.

Section 2.3

of the test report provides information on the coordinate systems and notation for the bump configurations tested.

See Section 4.1

of the test report for details on the experimental test conditions.

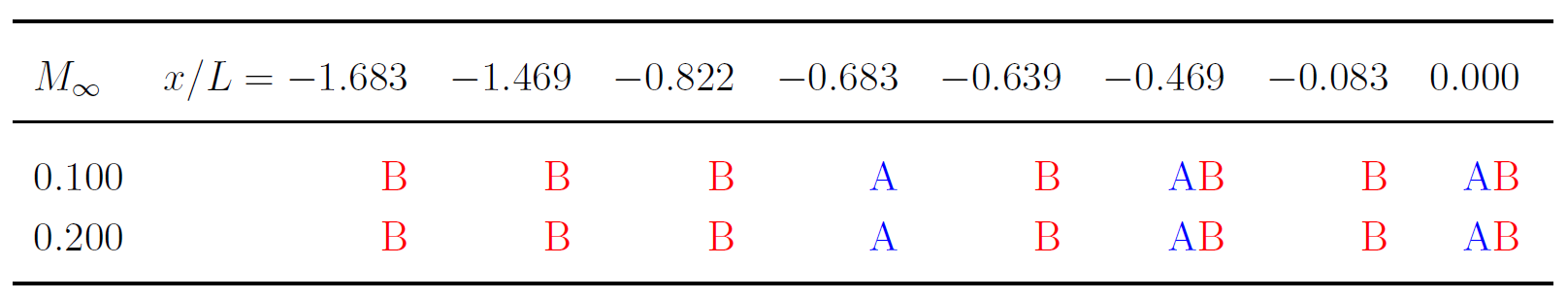

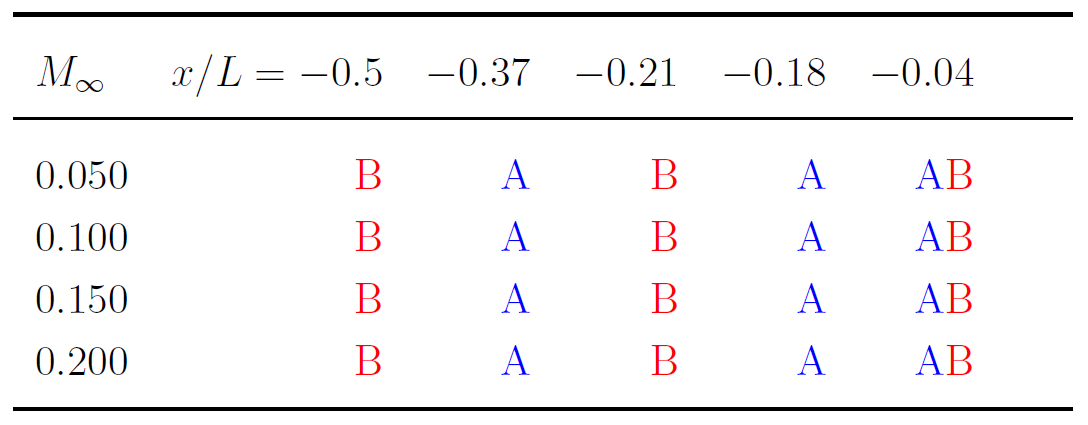

5.5.1. Hot-wire: Upstream Boundary Layer Profile Development

The hot-wire anemometry and traversing system described in

Section 2.4.3 of the

test report was used to obtain mean velocity and turbulence profiles of the boundary layer upstream of the bump apex on centerline.

See Section 4.2.1

in the test report for more information on the data obtained.

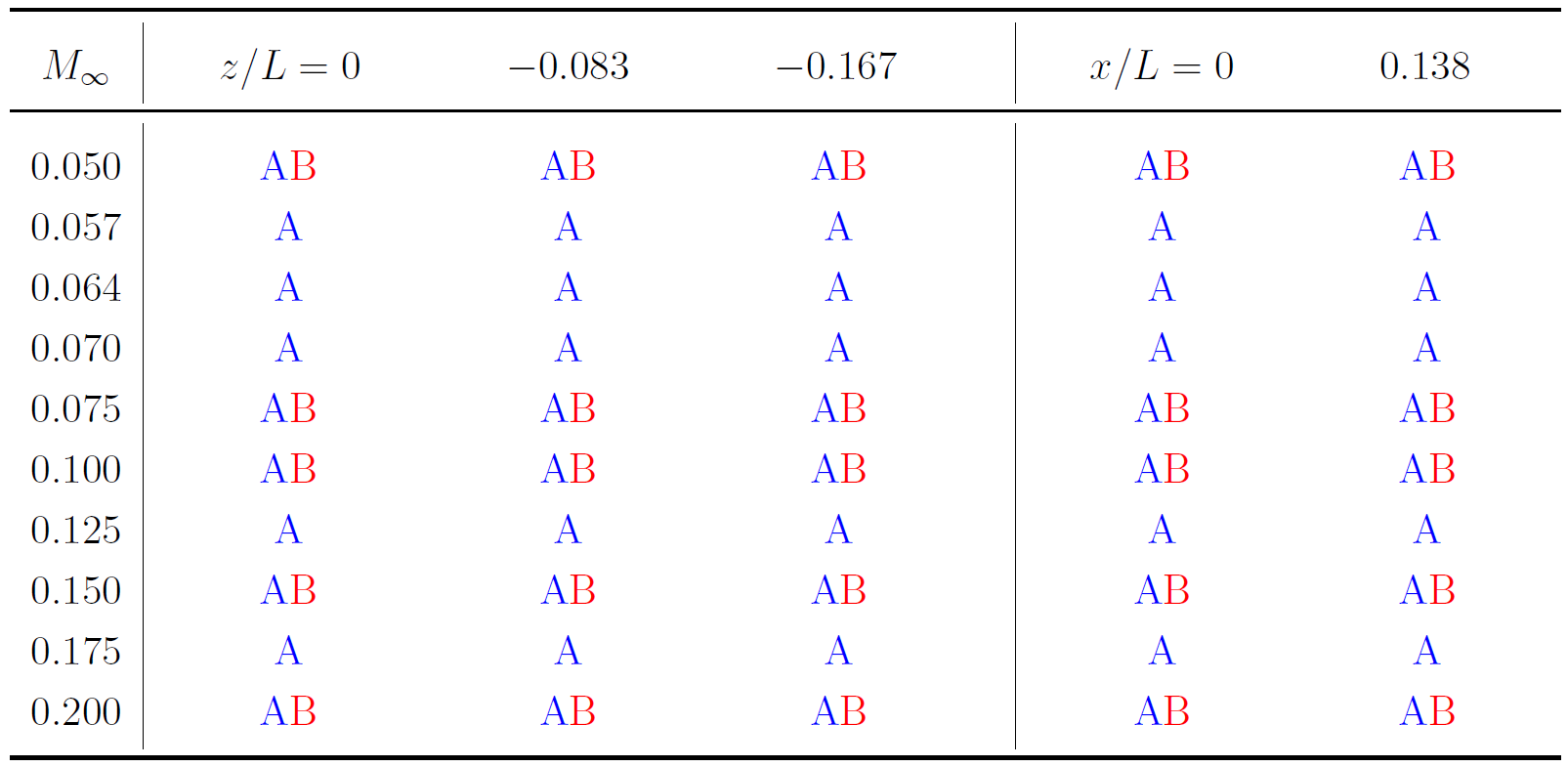

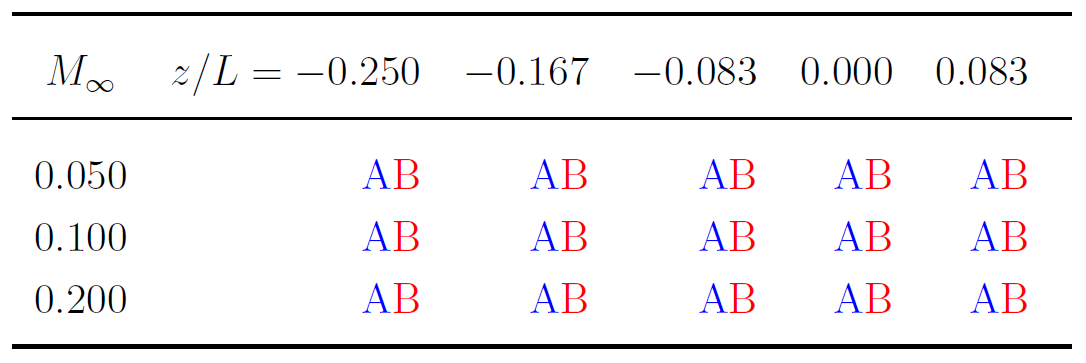

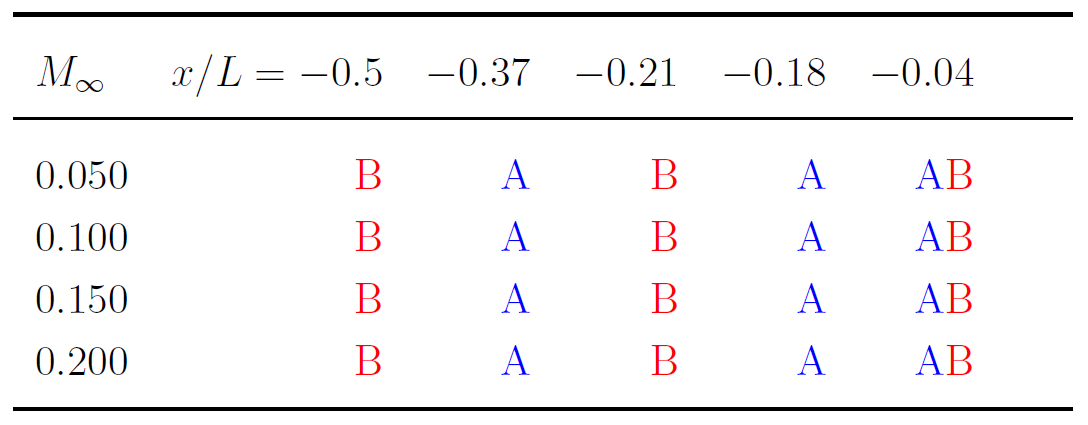

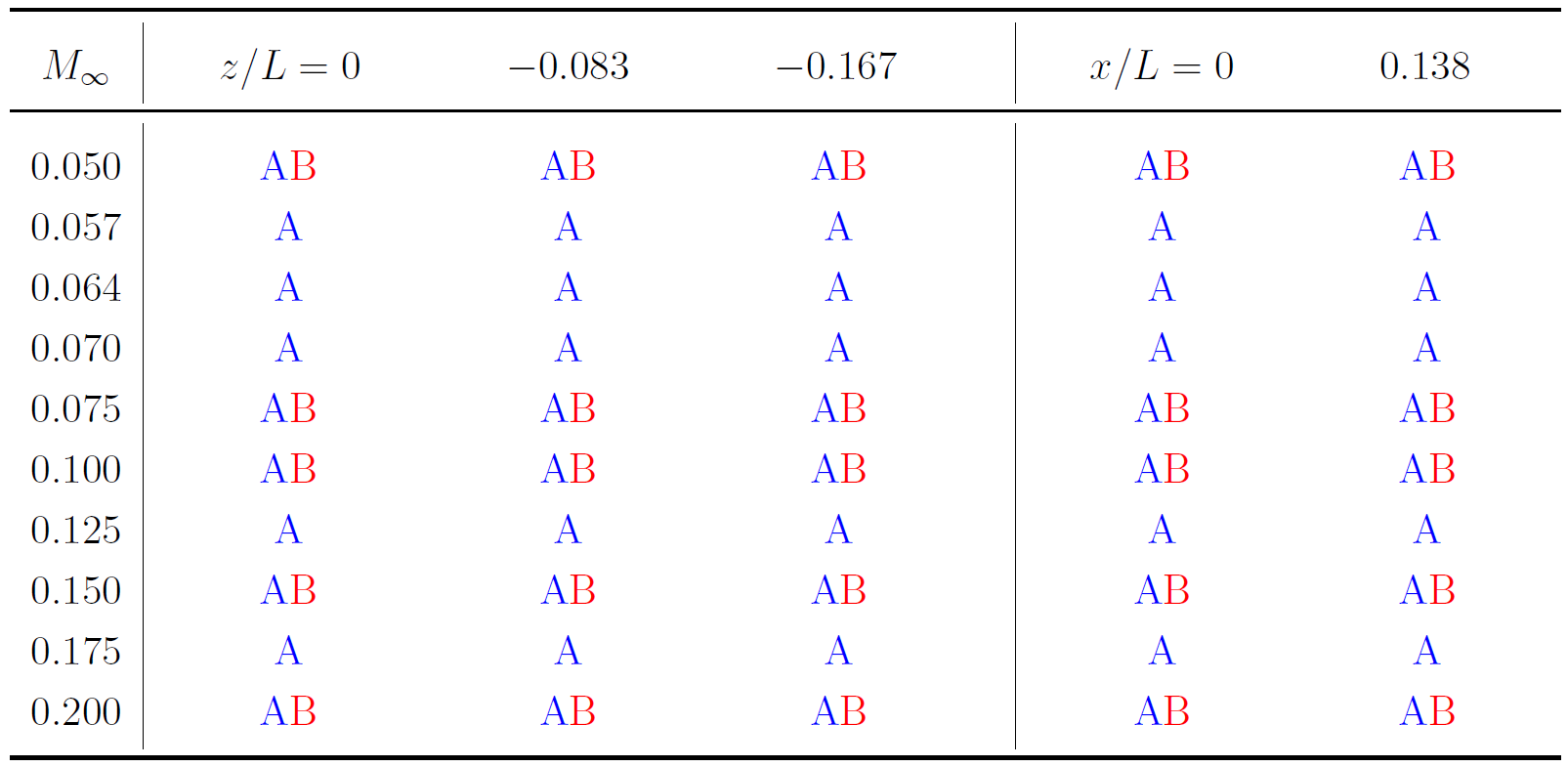

The following table outlines where hot-wire data were obtained and for what conditions:

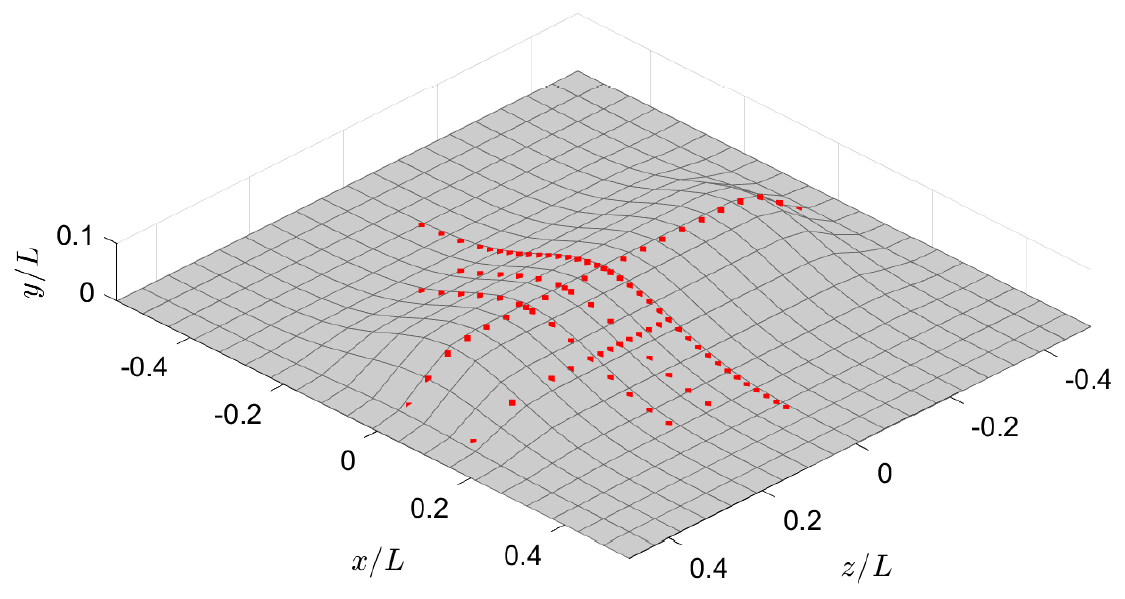

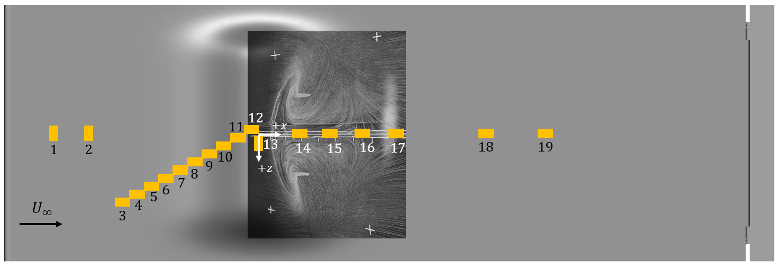

The following figure visually depicts where the hot-wire data were obtained relative to the bump:

A zip file containing the hot-wire data obtained upstream of the bump can be downloaded here:

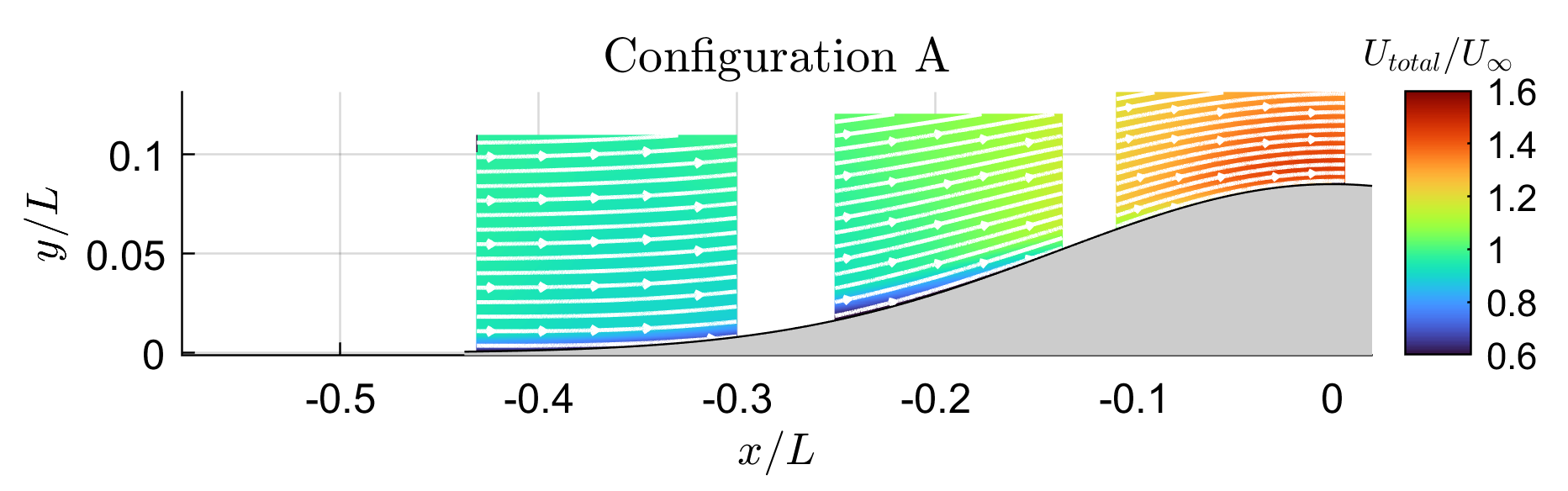

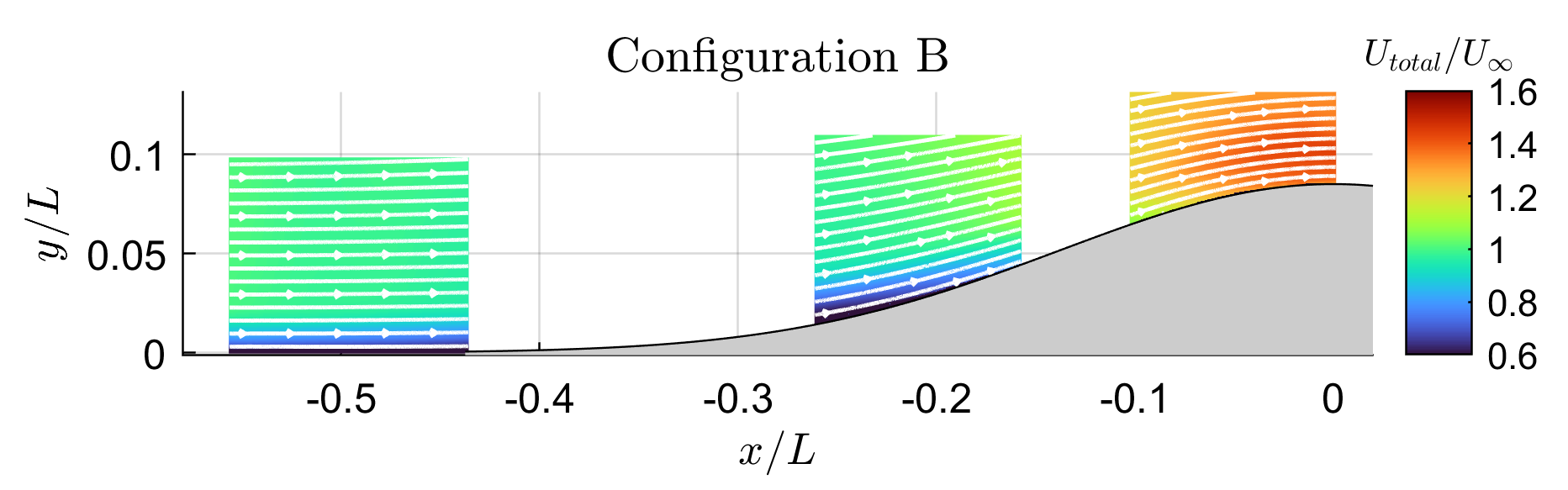

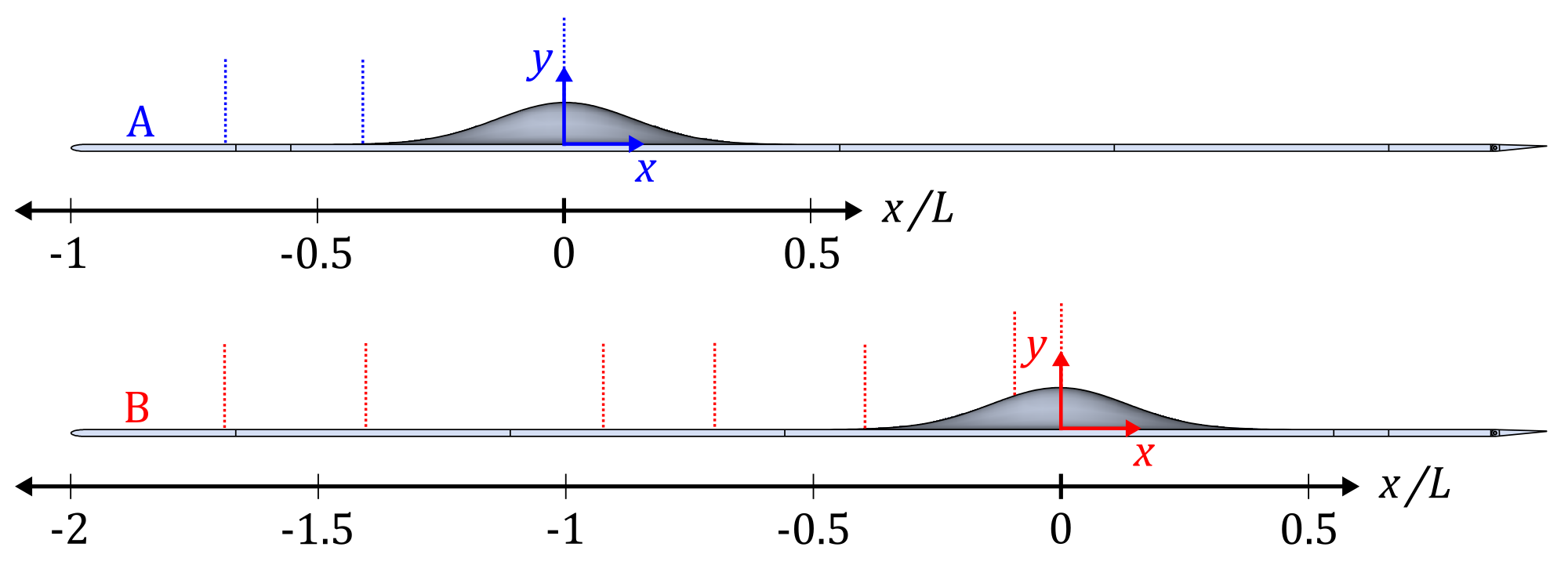

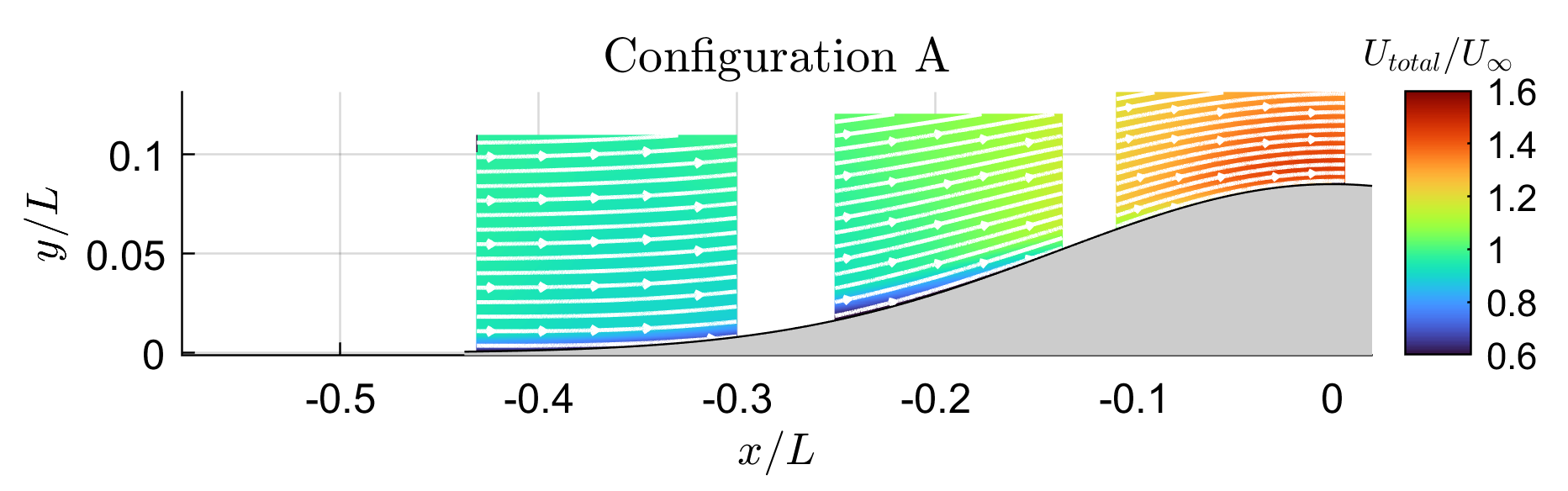

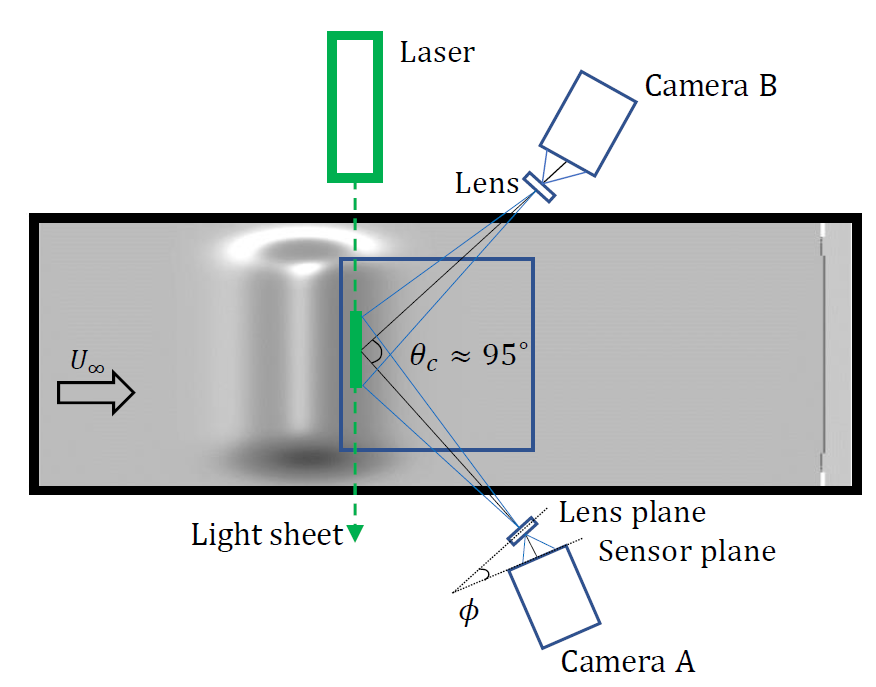

5.5.2. Stereoscopic PIV (SPIV): Upstream Flow Field Development on Centerline

The upstream SPIV setup described in

Section 2.4.6.2 of the

test report was used to measure the mean velocities and Reynolds stresses upstream of the bump apex. See

Section 4.2.2

in the test report for more information on the data obtained.

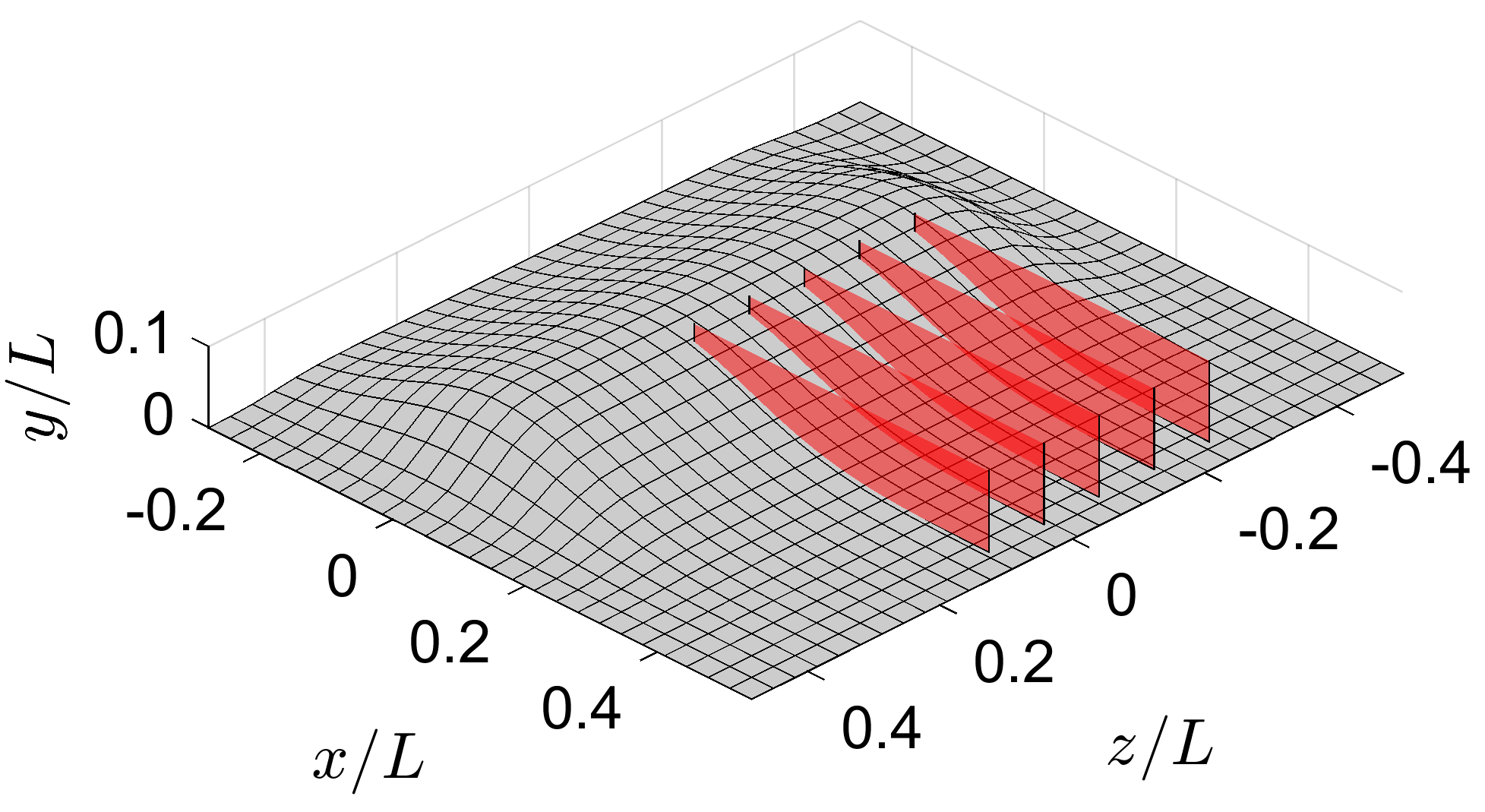

The following table outlines where SPIV data were obtained and for what conditions.

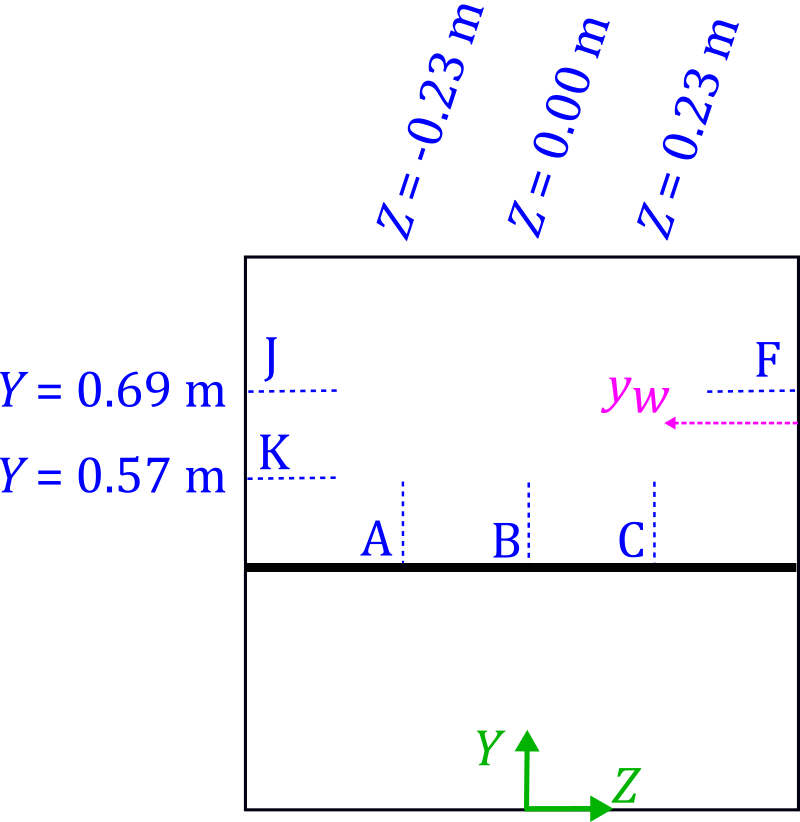

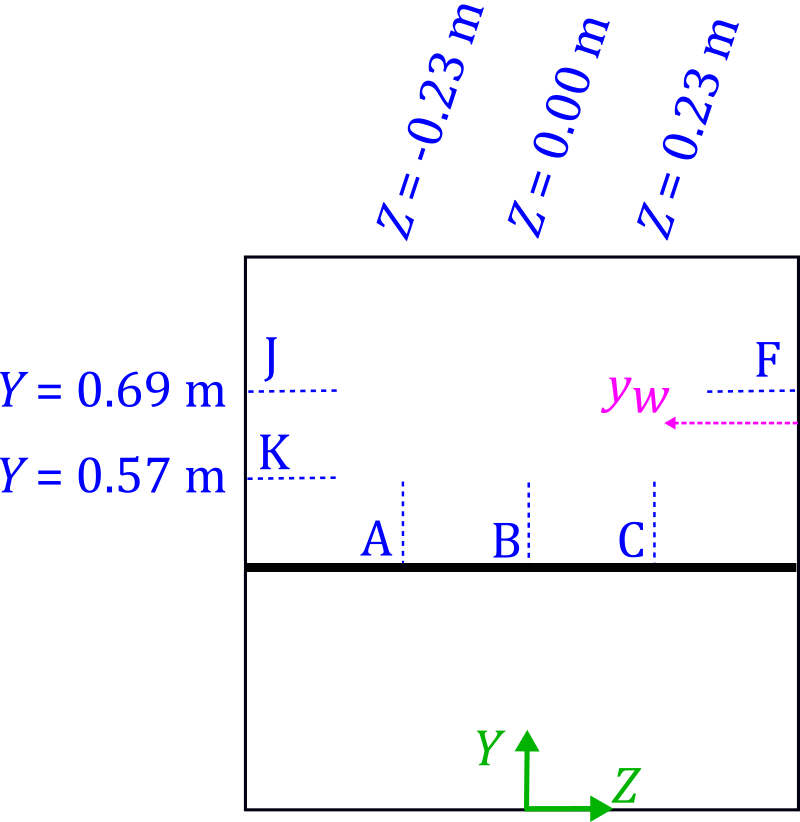

The following figures visually depict where the SPIV data were obtained relative to the bump.

A zip file containing the SPIV data obtained upstream of the bump can be downloaded here:

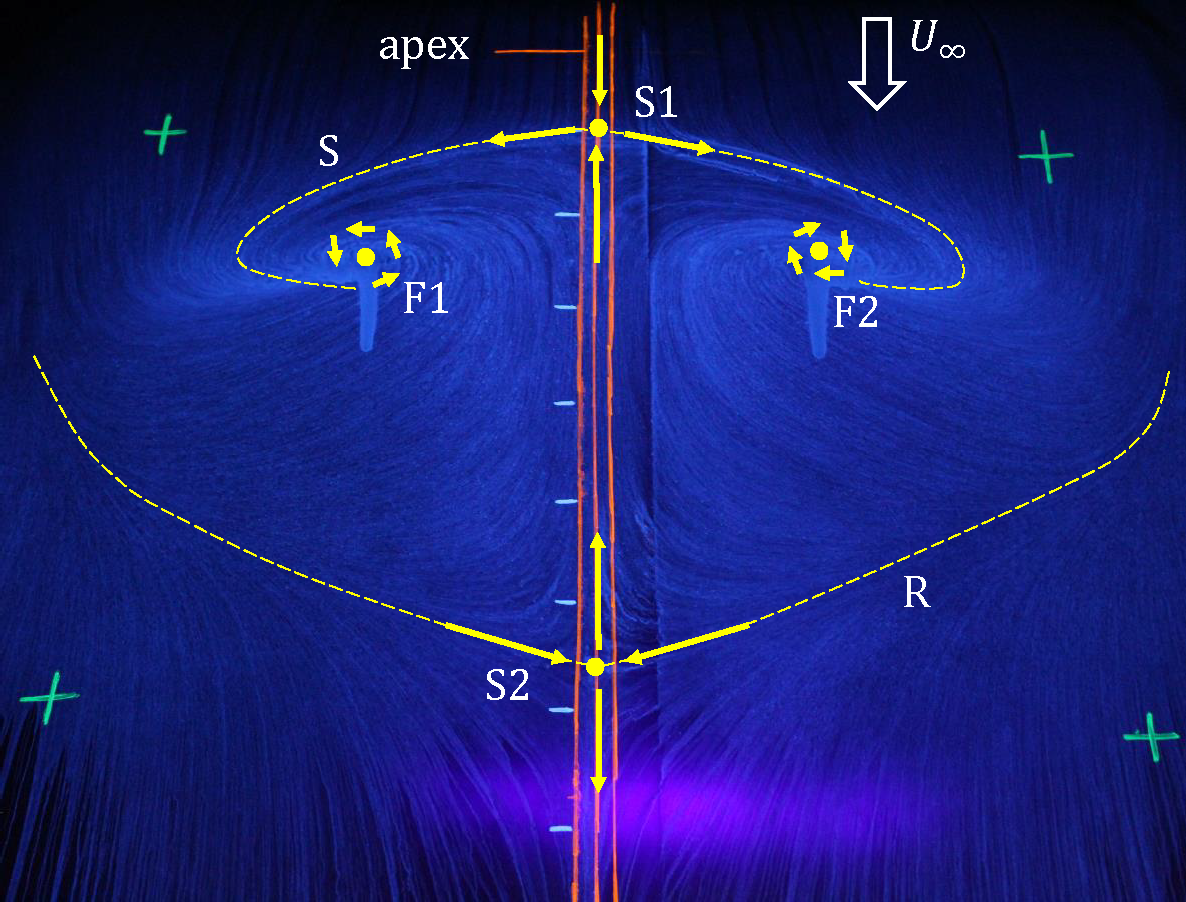

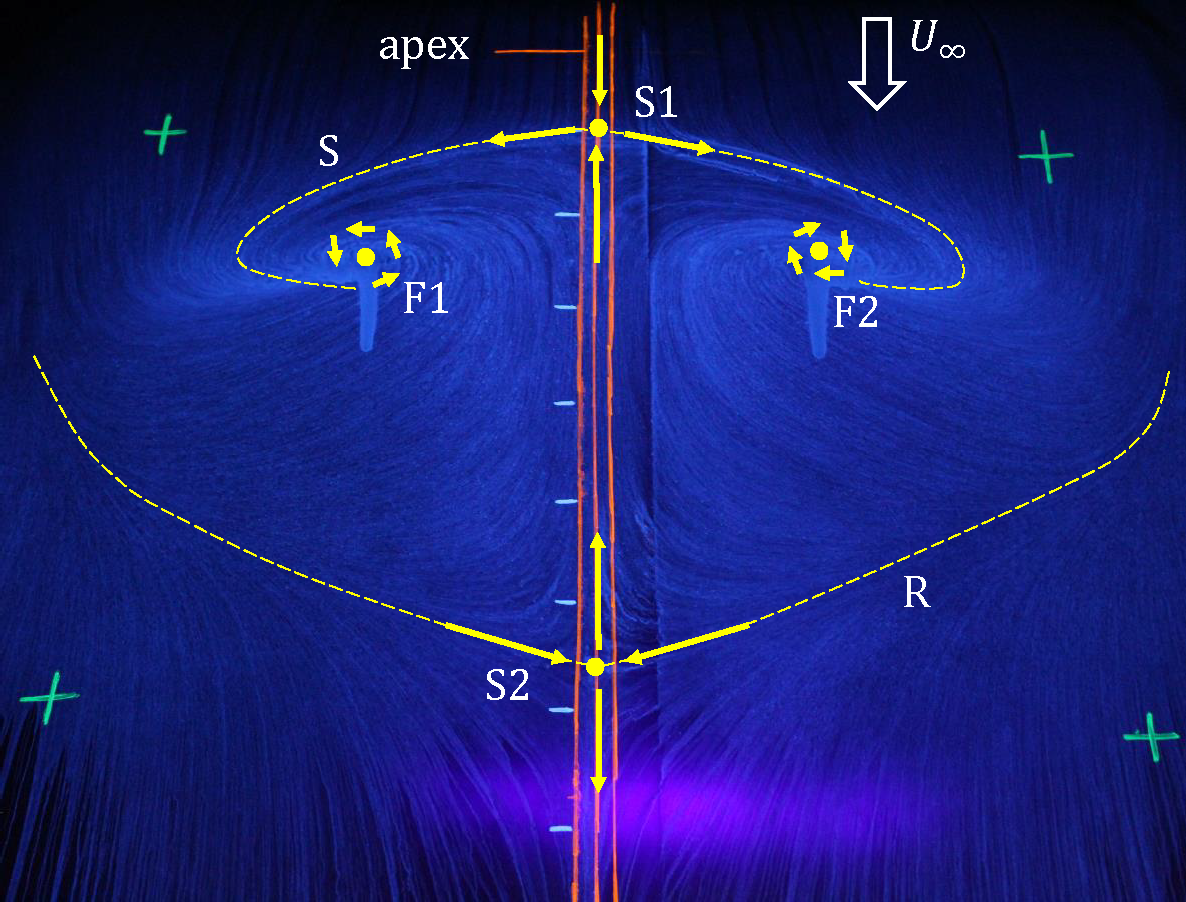

5.5.3. Fluorescent Oil Flow Visualization: Bump Surface Streamlines Within the Separation

The fluorescent oil mixture described in

Section 2.4.1

was applied to the downstream region of the bump to visualize the time-mean surface streamlines produced by the separated flow.

See Section 4.3

in the test report for more information on the images obtained.

The following figure is an example fluorescent oil flow image obtained at M=0.2 for Configuration A.

In the image the apex of the bump is indicated by the annotation and the bump centerline is delineated with three parallel orange lines.

The location of the surface foci at M=0.2 for Configuration A were extracted by applying a

photogrammetry technique to map the fluorescent oil flow image onto the 3D bump surface.

The foci locations are provided below in local bump-relative coordinates and have an

estimated uncertainty of +/-2mm, based on how the center of the foci were visually identified.

F1: (x,z) = (124.7, 113.8) mm

F2: (x,z) = (129.3, -109.6) mm

Fluorescent oil flow images are provided for both configuration A and B at M=0.1 and M=0.2.

A zip file containing the images can be downloaded here:

5.5.4. Pressure Taps: Bump Surface Static Pressure

The static pressure taps described in

Section 2.4.7.1

of the test report were used to measure the mean surface pressure field along the bump.

The ports were aligned on five arrays, three arrays in the streamwise direction and two arrays in the spanwise direction.

See Section 4.4.1

in the test report for more information on the data obtained.

The following table outlines where the static pressure data were obtained and for what conditions.

The following figure visually depicts where the static pressure data were obtained on the bump.

A zip file containing the static pressure data obtained on the bump can be downloaded here:

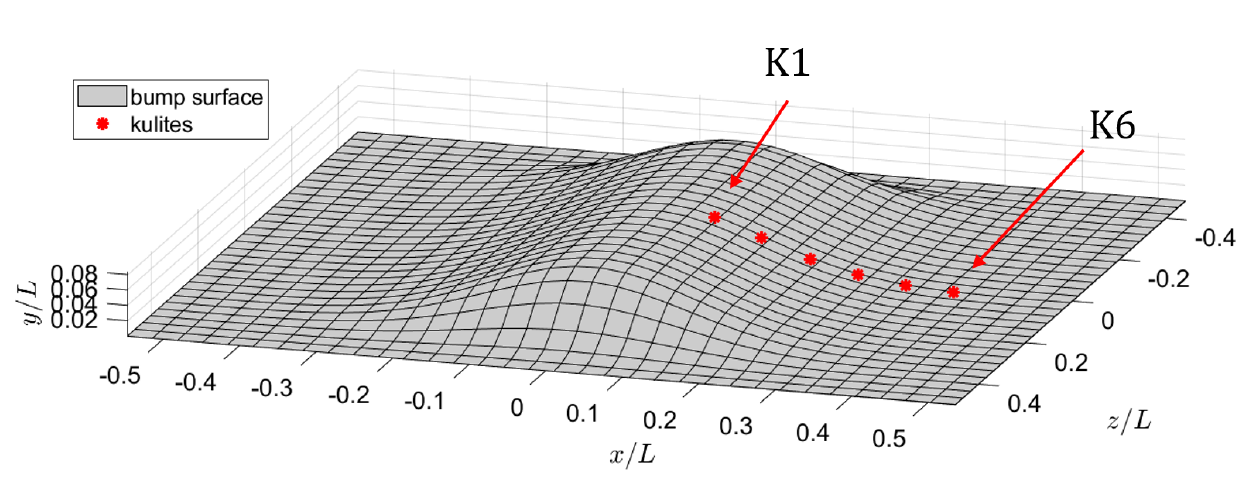

5.5.5. Kulites: Bump Surface Dynamic Pressure

The Kulite dynamic pressure sensors described in

Section 2.4.7.2

of the test report were used to measure instantaneous pressure fluctuations downstream of the bump apex.

See Section 4.4.2

in the test report for more information on the data obtained.

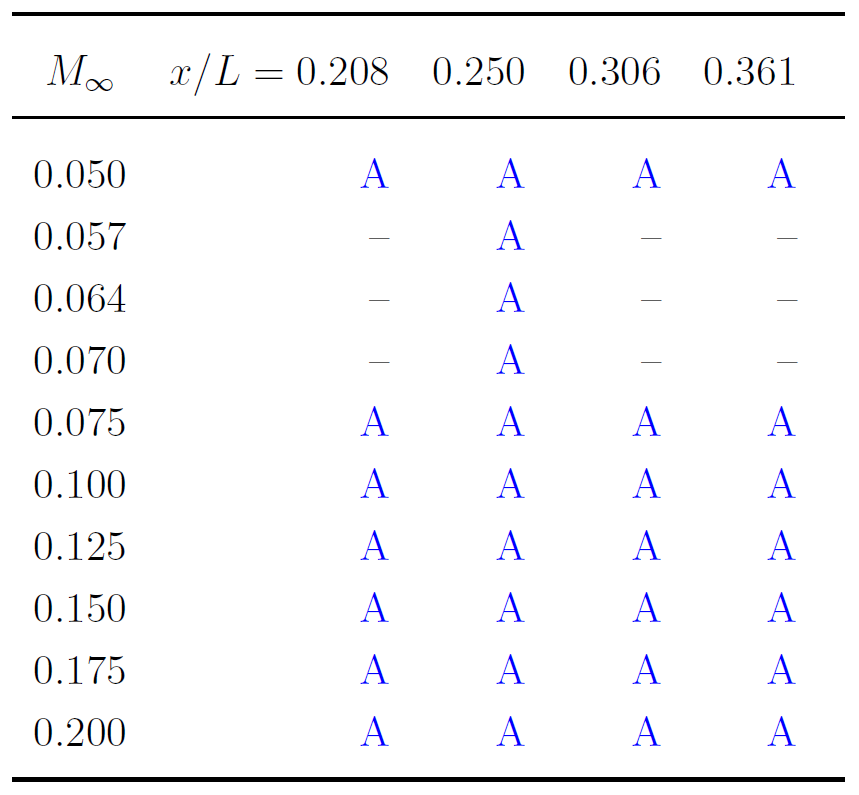

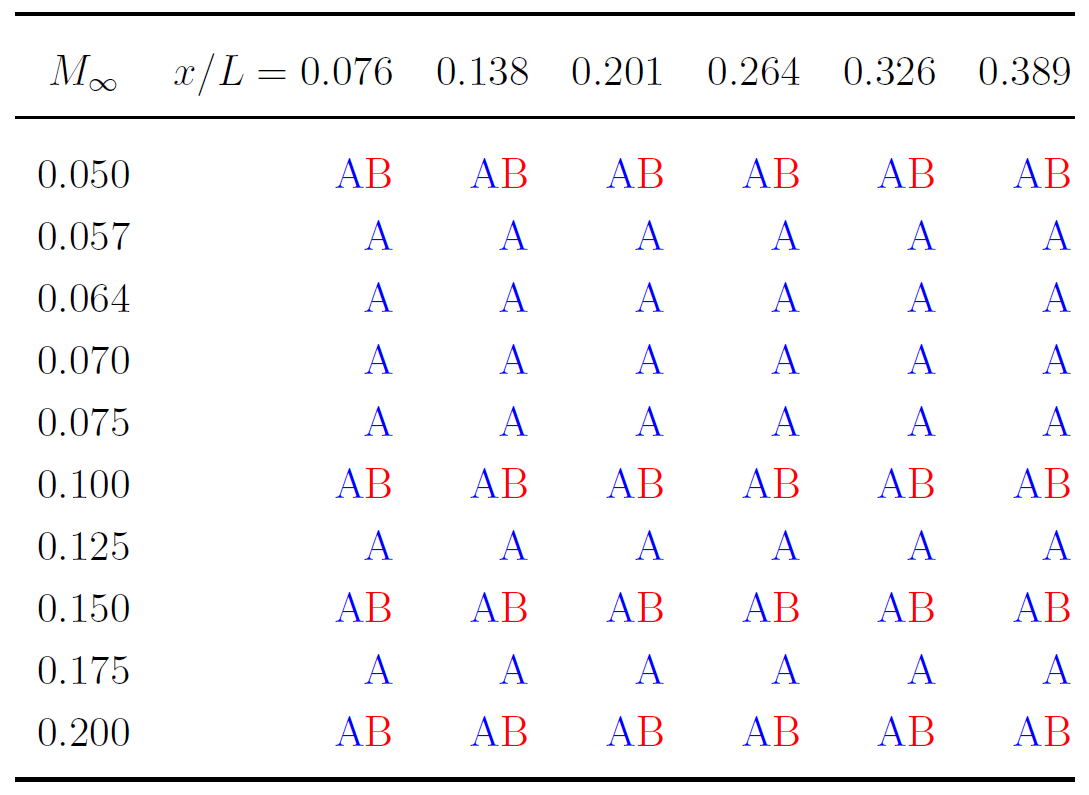

The following table outlines where the dynamic pressure data were obtained and for what conditions.

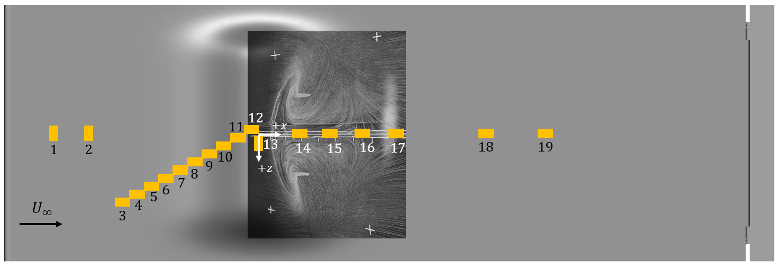

The following figure visually depicts where the Kulite sensors were installed on the bump.

A zip file containing the dynamic pressure data obtained on the bump can be downloaded here:

5.5.6. Oil Film Interferometry (OFI): Bump Surface Skin Friction

The photogrammetric OFI technique described in

Section 2.4.4

in the test report was used to measure the skin friction coefficient along the bump.

See Section 4.5

in the test report for more information on the data obtained.

The following figure depicts an example distribution of OFI measurements along the splitter plate and bump.

The OFI measurements were made at M=0.05, 0.1 and 0.2 for bump configurations A and B.

A zip file containing the skin friction measurements obtained on the bump using OFI can be downloaded here:

5.5.7 Particle Image Velocimetry (PIV): Downstream Flow Field on Streamwise Planes

The PIV setup described in

Section 2.4.5

of the test report was used to measure two-component mean velocity and

Reynolds stresses in the separated flow region downstream of the bump apex.

See Section 4.6

in the test report for more information on the data obtained.

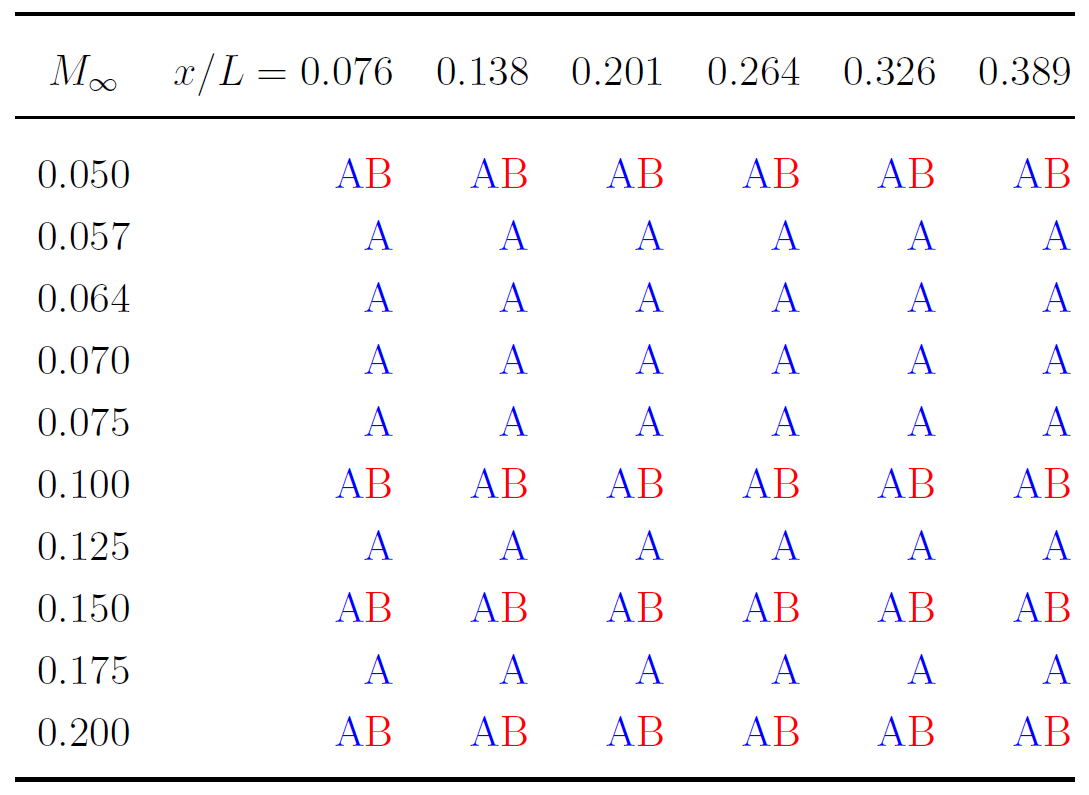

The following table outlines where the downstream PIV data were obtained and for what conditions.

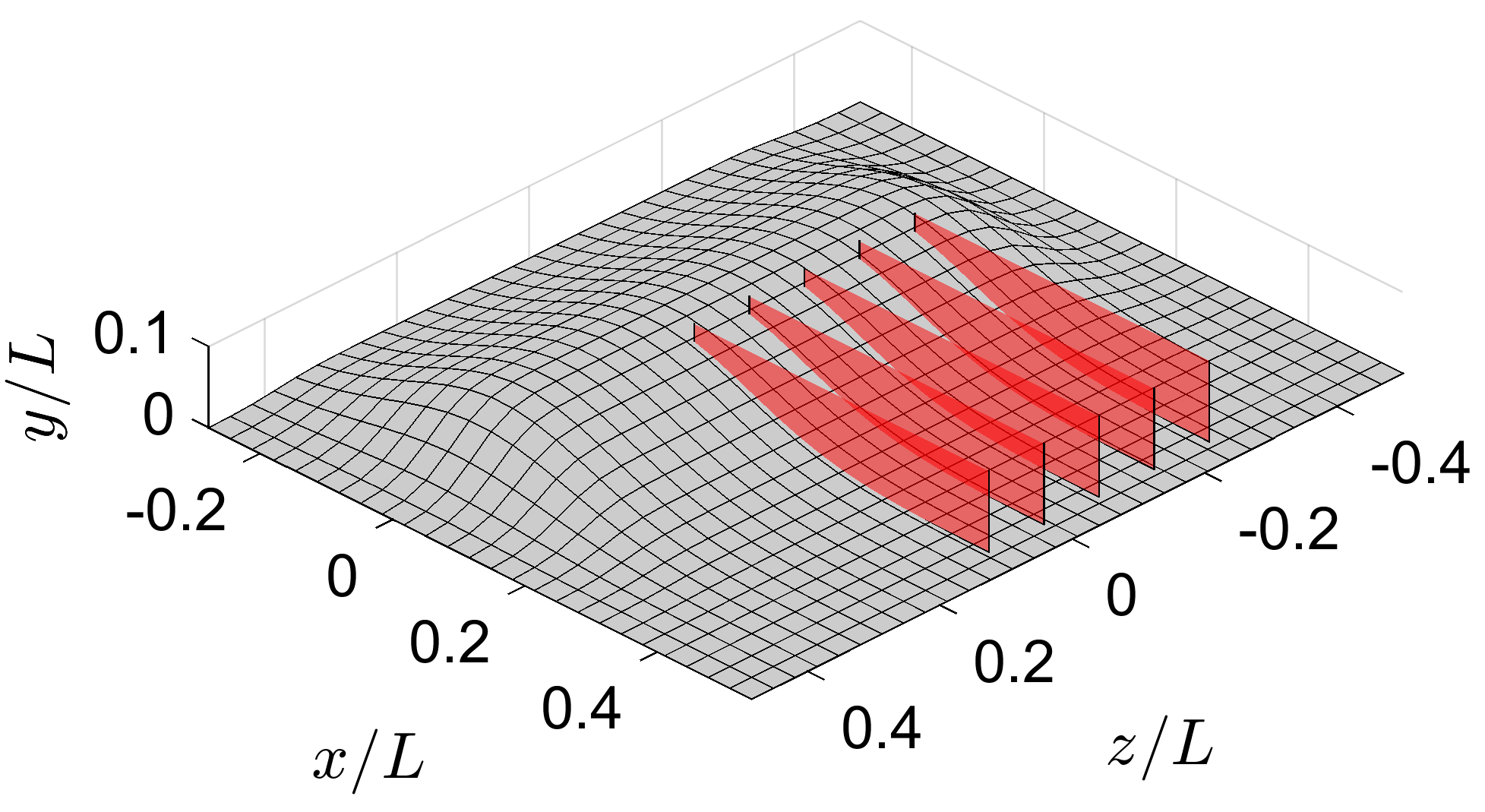

The following figure visually depicts on what planes PIV data were obtained on the downstream side of the bump.

A zip file containing the downstream PIV data can be downloaded here:

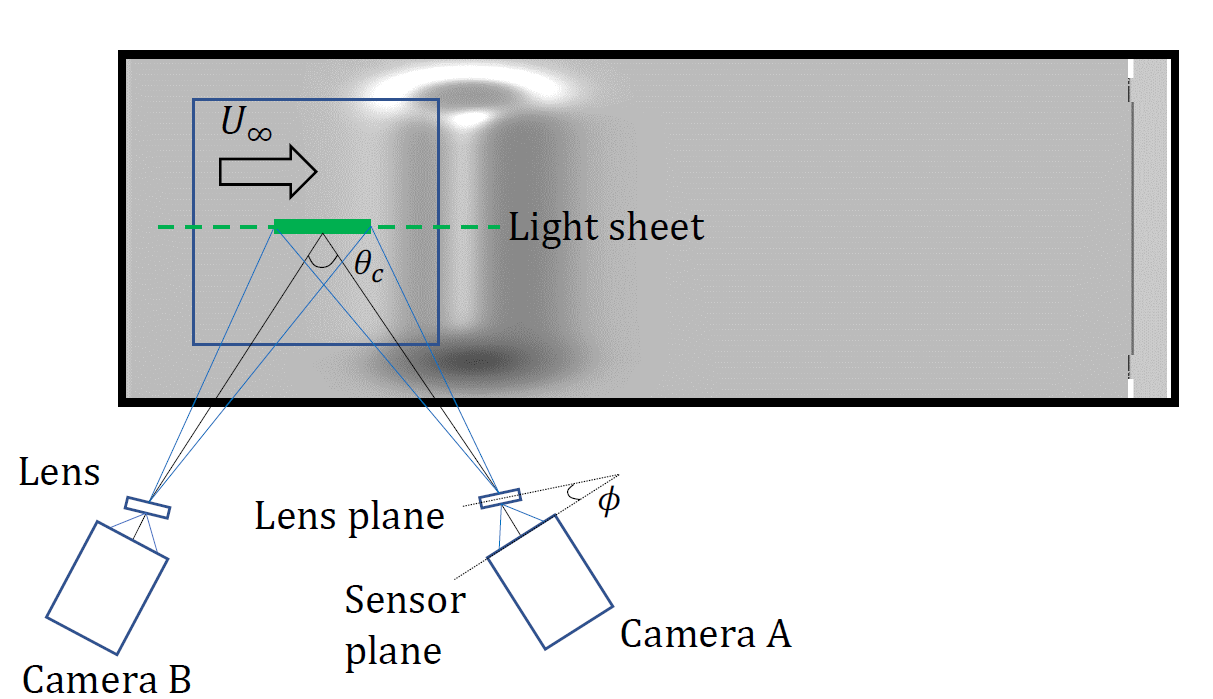

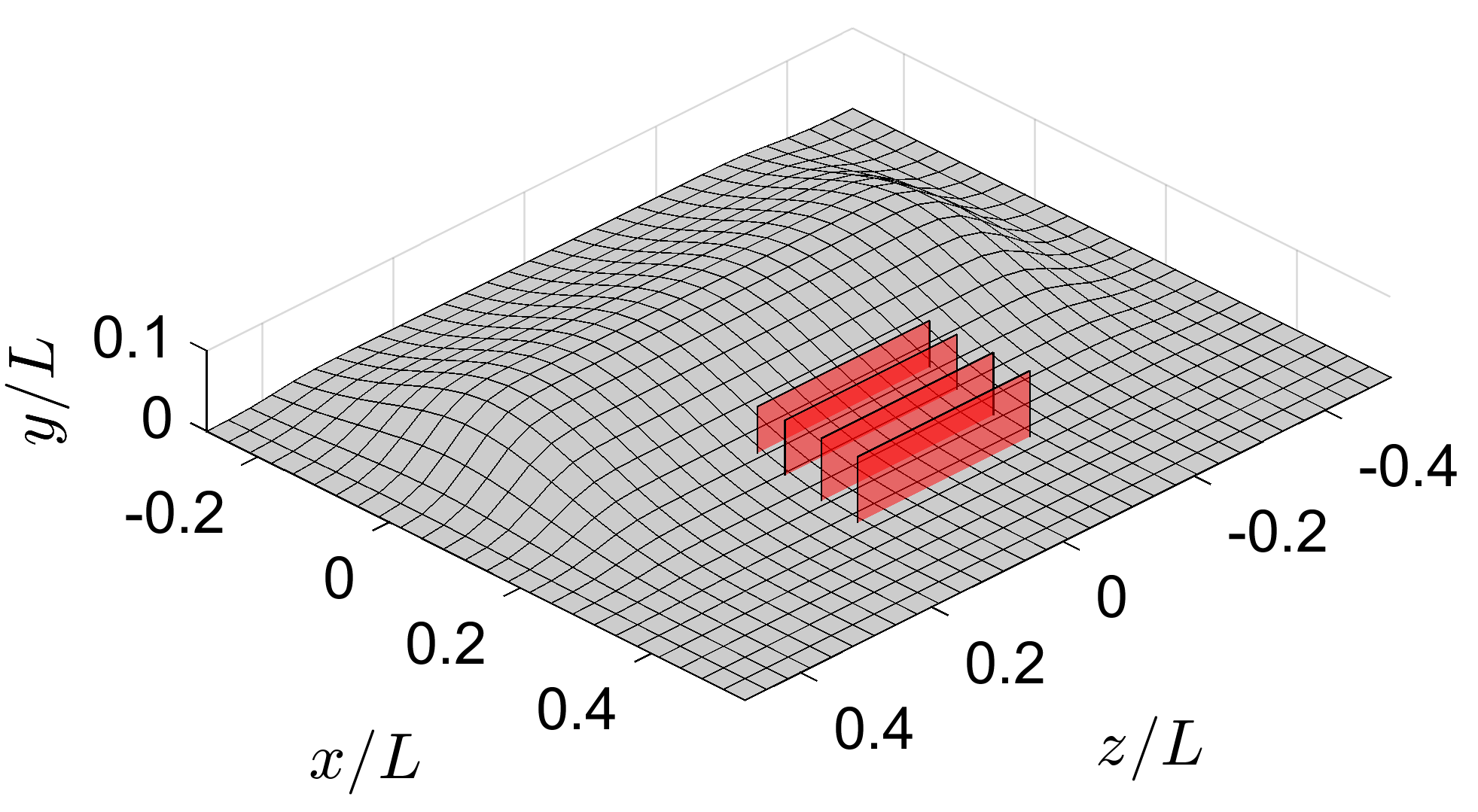

5.5.8 Stereoscopic PIV (SPIV): Downstream Flow Field on Cross-Planes

The cross planar SPIV setup described in

Section 2.4.6.1

was used to measure three-component mean velocity and Reynolds stresses downstream of the bump apex.

See Section 4.7

in the test report for more information on the data obtained.

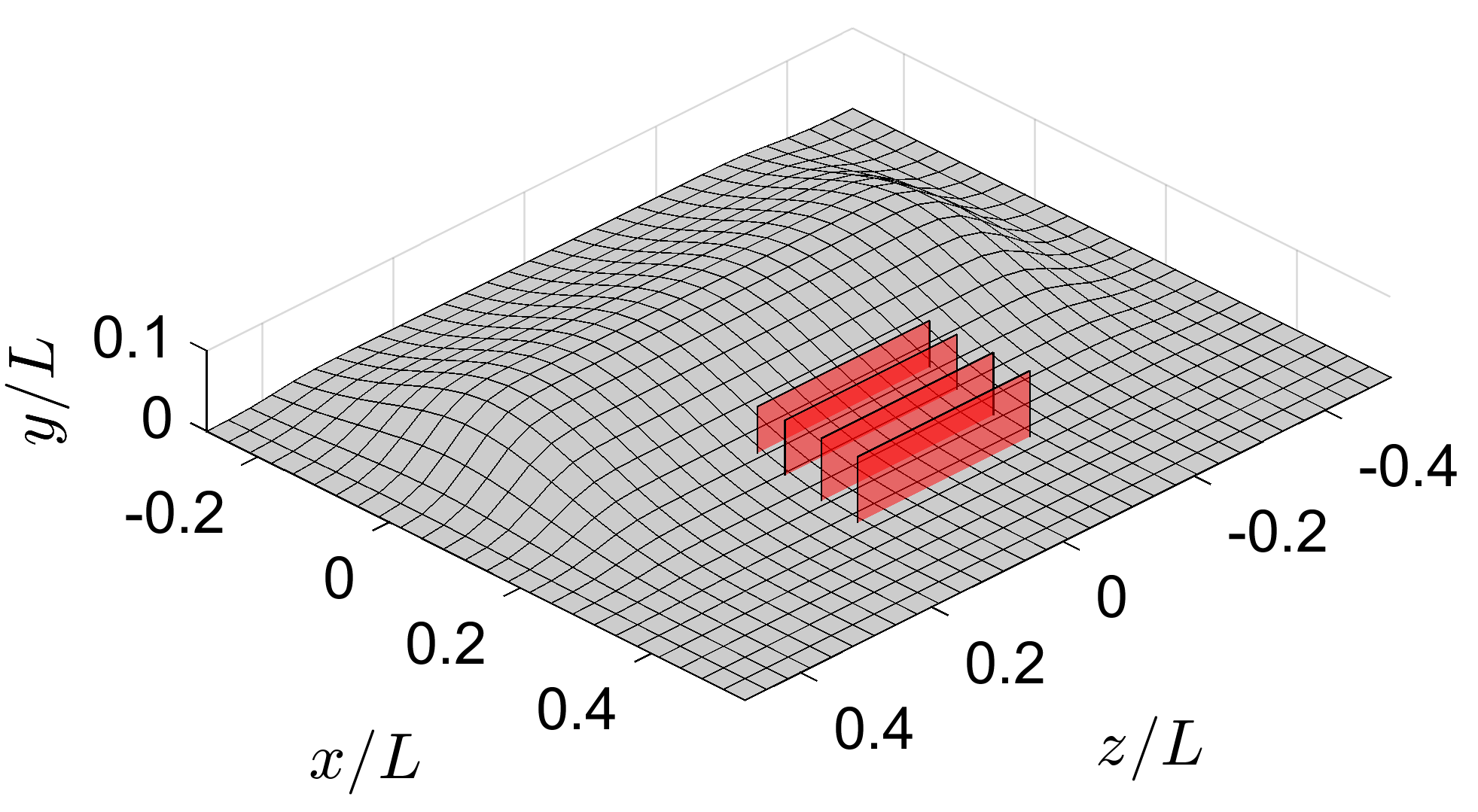

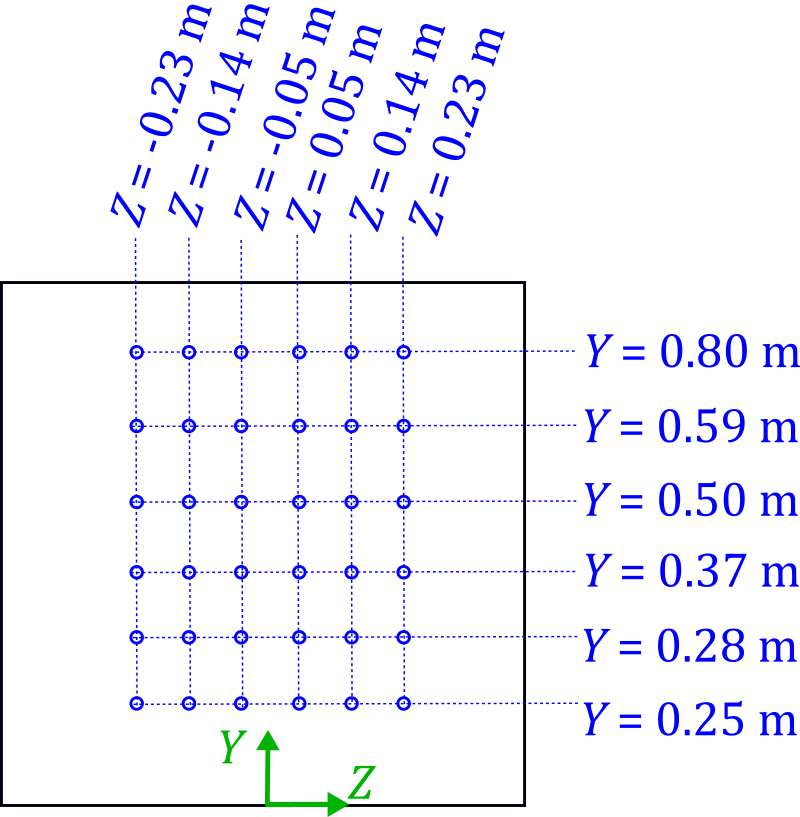

The following table outlines where the downstream SPIV data were obtained and for what conditions.

The following figure visually depicts on what planes SPIV data were obtained on the downstream side of the bump.

A zip file containing the downstream SPIV data can be downloaded here:

6. List of Related CFD Papers

The following is a list of known CFD papers that report scale-resolving computations of the SBSE configuration (including

both the full configuration as well as a centerplane or center-region "slice").

DNS (Direct Numerical Simulation) Papers:

- Uzun, A., Malik, M. R. (2021). Simulation of a turbulent flow subjected to favorable and adverse pressure gradients.

Theoretical and Computational Fluid Dynamics, 35, 293-329,

https://doi.org/10.1007/s00162-020-00558-4.

DNS data from this paper is provided on the page:

DNS: Gaussian Bump at Two Reynolds Numbers

- Shur, M. L., Spalart, P. R., Strelets, M. K., Travin, A. K. (2021). Direct numerical simulation of the

two-dimensional speed bump flow at increasing Reynolds numbers. International Journal of Heat and Fluid Flow, 90, 108840,

https://doi.org/10.1016/j.ijheatfluidflow.2021.108840.

- Balin, R., Jansen, K. E. (2021). Direct numerical simulation of a turbulent boundary layer over a bump with

strong pressure gradients. Journal of Fluid Mechanics, 918, A14,

https://doi.org/10.1017/jfm.2021.312.

- Uzun, A., Malik, M. R. (2022). High-fidelity simulation of turbulent flow past Gaussian bump.

AIAA Journal, 60(4), 2130-2149,

https://doi.org/10.2514/1.J060760.

DNS data from this paper is provided on the page:

DNS: Gaussian Bump at Two Reynolds Numbers

WRLES (Wall-Resolved Large-Eddy Simulation) Papers:

- Wright, J. R., Balin, R., Jansen, K. E., Evans, J. A. (2021). Unstructured LES_DNS of a turbulent boundary

layer over a Gaussian bump. In AIAA Scitech 2021 Forum (AIAA-2021-1746),

https://doi.org/10.2514/6.2021-1746.

- Uzun, A., Malik, M. R. (2022). A Dynamic Nonlinear Subgrid-Scale Model for Large-Eddy Simulation

of Complex Turbulent Flows, NASA/TM-20220013891,

https://ntrs.nasa.gov/citations/20220013891.

- Rizzetta, D. P., Garmann, D. J. (2023). Wall-resolved large-eddy simulation of flow over a

three-dimensional gaussian bump. In AIAA SCITECH 2023 Forum (AIAA-2023-0286),

https://doi.org/10.2514/6.2023-0286.

- Rizzetta, D. P., Garmann, D. J. (2023). Wall-Resolved Large-Eddy Simulation of Flow over a Parametric

Set of Gaussian Bumps. In AIAA AVIATION 2023 Forum (AIAA-2023-3983),

https://doi.org/10.2514/6.2023-3983.

- Rizzetta, D. P., Garmann, D. J. (2023). Arch Vortex in Flow over a Three-Dimensional Gaussian Bump.

AIAA Journal, 61(11), 5176-5179,

https://doi.org/10.2514/1.J062876.

WMLES/DDES (Wall-Modeled Large-Eddy Simulation/Delayed Detached Eddy Simulation) Papers:

- Balin, R., Jansen, K. E., Spalart, P. R. (2020). Wall-modeled LES of flow over a Gaussian bump with

strong pressure gradients and separation. In AIAA Aviation 2020 Forum (AIAA-2020-3012),

https://doi.org/10.2514/6.2020-3012.

- Iyer, P. S., Malik, M. R. (2021). Wall-modeled LES of flow over a Gaussian bump.

In AIAA Scitech 2021 Forum (AIAA-2021-1438),

https://doi.org/10.2514/6.2021-1438.

- Gray, P. D., Gluzman, I., Thomas, F., Corke, T., Lakebrink, M., Mejia, K. (2021). A new validation

experiment for smooth-body separation. In AIAA Aviation 2021 Forum (AIAA-2021-2810),

https://doi.org/10.2514/6.2021-2810.

- Whitmore, M. P., Griffin, K. P., Bose, S. T., Moin, P. (2021). Large-eddy simulation of a Gaussian

bump with slip-wall boundary conditions. Center for Turbulence Research Annual Research Briefs, 45-58,

https://web.stanford.edu/group/ctr/ResBriefs/2021/06_Whitmore.pdf.

- Agrawal, R., Whitmore, M., Griffin, K., Moin, P. (2021). Dynamic modeling of non-Boussinesq

subgrid-scale models for large-eddy simulations. Center for Turbulence Research Annual Research Briefs, 31-43,

https://web.stanford.edu/group/ctr/ResBriefs/2021/05_Agrawal.pdf.

- Prakash, A., Balin, R., Evans, J. A., Jansen, K. E. (2022). Wall-modeled large eddy simulations of a

turbulent boundary layer over the Boeing speed bump at ReL= 2 million. In AIAA SciTech 2022 Forum (AIAA-2022-0338),

https://doi.org/10.2514/6.2022-0338.

- Iyer, P. S., Malik, M. R. (2022). Wall-modeled LES of turbulent flow over a two

dimensional Gaussian bump. ICCFD11 Paper, 204, 2022,

https://www.iccfd.org/iccfd11/assets/pdf/papers/ICCFD11_Paper-0204.pdf.

- Agrawal, R., Bose, S. T., Moin, P. (2022). Wall modeled LES of the Boeing speed bump using a

non-Boussinesq modeling framework. Center for Turbulence Research, Annual Research Briefs, 43-58,

https://web.stanford.edu/group/ctr/ResBriefs/2022/06_Agrawal.pdf.

- Agrawal, R., Whitmore, M. P., Griffin, K. P., Bose, S. T., Moin, P. (2022). Non-Boussinesq subgrid-scale

model with dynamic tensorial coefficients. Physical Review Fluids, 7(7), 074602,

https://doi.org/10.1103/PhysRevFluids.7.074602.

- Iyer, P. S., Malik, M. R. (2023). Wall-modeled LES of the three-dimensional speed bump

experiment. In AIAA SCITECH 2023 Forum (AIAA-2023-0253),

https://doi.org/10.2514/6.2023-0253.

- Gray, P. D., Lakebrink, M. T., Thomas, F. O., Corke, T. C., Gluzman, I., Straccia, J. (2023). Experimental

and Computational Evaluation of Smooth-Body Separated Flow over Boeing Bump. In AIAA AVIATION 2023 Forum (AIAA-2023-3981),

https://doi.org/10.2514/6.2023-3981.

- Arranz, G., Ling, Y., Lozano-Duran, A. (2023). Wall-modeled LES based on building-block flows:

Application to the Gaussian Bump. In AIAA AVIATION 2023 Forum (AIAA-2023-3984),

https://doi.org/10.2514/6.2023-3984.

- Zhou, D., Whitmore, M. P., Griffin, K. P., Bae, H. J. (2023). Large-Eddy Simulation of Flow over Boeing

Gaussian Bump Using Multi-Agent Reinforcement Learning Wall Model. In AIAA AVIATION 2023 Forum (AIAA-2023-3985),

https://doi.org/10.2514/6.2023-3985.

- Iyer, P. S., Malik, M. R. (2023). Assessing Reynolds Number Effects for flow over a Gaussian bump

using Wall-modeled LES. In AIAA AVIATION 2023 Forum (AIAA-2023-3982),

https://doi.org/10.2514/6.2023-3982.

Acknowledgements

The Boeing bump model geometry was developed by Philippe Spalart

(Senior Technical Fellow, the Boeing Company, Retired) in close

collaboration with Jeffrey Slotnick (Technical Fellow, the Boeing Company)

and the New Technologies and Services (NTS) group under Professor Strelets

in St. Petersburg. The wind tunnel experiments were conducted by the

University of Notre Dame. Program oversight and accompanying CFD analysis

performed by Boeing Research & Technology.

This work was funded through a cooperative agreement between the

Office of Naval Research, the National Aeronautics and Space Administration,

the Army Research Office, the Air Force Research Lab, and The Boeing Company.

Government funding for the work was provided through ONR Cooperative

Agreement No. N00014-20-2-1002. Any opinions, findings, and conclusions

or recommendations expressed in this material are those of the authors

and do not necessarily reflect the views of the Office of Naval Research.

Return to: Data from Experiments - Intro Page

Return to: Turbulence Modeling Resource Home Page

Recent significant updates:

02/09/2024 - updated the experimental test report, and added the CFD test report

08/28/2023 - posted final data

Privacy Act Statement

Accessibility Statement

Responsible NASA Official:

Ethan Vogel

Page Curator:

Clark Pederson

Last Updated: 10/08/2024